Mig Welding Gun Accessory Kit Review

Discover the essential features of the Mig Welding Gun Accessory Kit that could transform your welding experience—find out what makes it a must-have!

Discover the essential features of the Mig Welding Gun Accessory Kit that could transform your welding experience—find out what makes it a must-have!

Get ready to discover why the Bar Clamps 4-Pack is the essential tool for your next project; you'll be amazed at their performance.

Perfect for tight spaces, the YESWELDER Tig Welding Torch WP-17FV offers exceptional maneuverability and durability—discover what seasoned welders love about this model!

Looking for the perfect soldering aid? Discover how the Magnetic Helping Hands Soldering Holder can transform your projects in ways you never imagined.

Sleek design and impressive features make the M-T Helping Hands Soldering Station a must-have tool—discover what sets it apart from the competition.

Observe the exceptional features of IRWIN VISE-GRIP Locking Pliers that promise durability and control—discover what makes them a must-have tool.

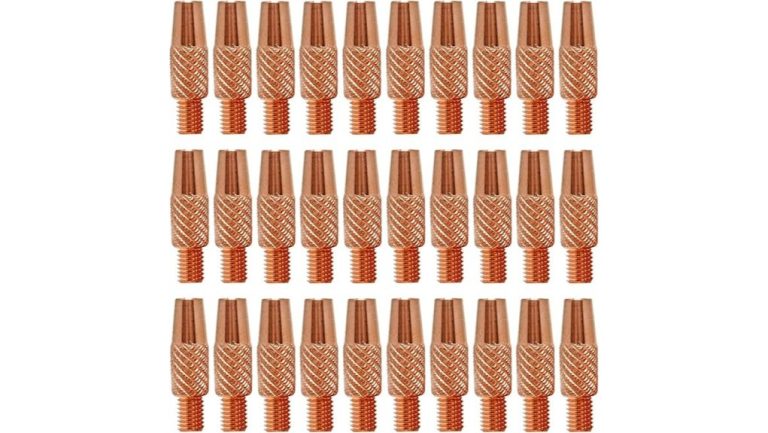

Keep your welding projects seamless with the Mig Welding Contact Tips 186406, but discover why these tips are a game changer for your welder.

Sleek and multifunctional, MIG Welding Pliers offer unmatched versatility for welders—discover how they can elevate your welding experience.

Outstanding performance and reliability define the T-Style Welding Ground Clamp—discover how it stands up in real-world welding scenarios.

Looking for a durable solution for your gardening and DIY projects? Discover how SEBOSS hardware cloth can transform your outdoor space.