You want a plasma cutter that saves time, gives cleaner cuts and expands what you can build in your garage or shop. Choosing the right Yeswelder model matters because these machines vary in power, portability and features like pilot arc or a built‑in compressor, and the right pick makes your projects easier, faster and often cheaper in the long run. This guide highlights the models worth considering so you can match a cutter to your workflow and budget.

Top Picks

|

Category |

Product |

Score |

|---|---|---|

|

🏆 Best Overall |

92/100 |

|

|

💰 Best Value |

82/100 |

|

|

🔰 Best Multi-Process |

90/100 |

|

|

🚀 Best Compact Power |

89/100 |

|

|

🎯 Best Workhorse |

87/100 |

|

|

💼 Best For Jobsite |

84/100 |

|

|

⚡ Best With Built-In Compressor |

88/100 |

|

|

🛠️ Best All-In-One |

91/100 |

|

|

🎛️ Best For CNC |

95/100 |

|

|

🏅 Best Rated |

94/100 |

How We Picked

You need a cutter that fits your projects and shop setup, so we focused on a few practical factors. We evaluated power and output (amps, severance vs clean cut), whether the unit runs on 110V and 220V, and the presence of pilot arc or blowback start for painted or rusty metal. Portability, build quality and useful extras like a built‑in compressor or multi‑process capability matter if you move between jobs or want one box for many tasks.

We also weighed real user feedback on reliability, consumable life and vendor support so you get a machine that performs day after day.

You get a surprisingly capable, portable cutter that feels at home in a garage or a small shop. It runs on 110V or 220V so you can use it where you work and the non-touch pilot arc helps when you’re cutting painted or rusty metal. The four modes cover most jobs from simple plate cuts to grid work and light gouging, so it’s useful for daily maintenance and larger DIY projects. If you want a versatile tool that expands what you can tackle without adding a bunch of extra gear, this is one to consider.

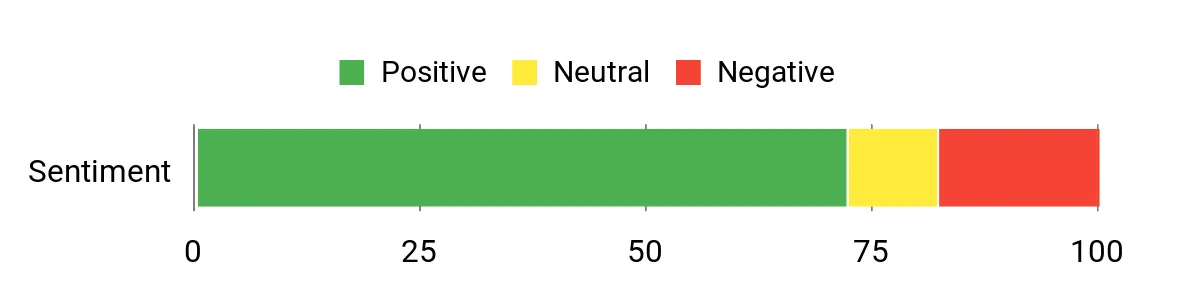

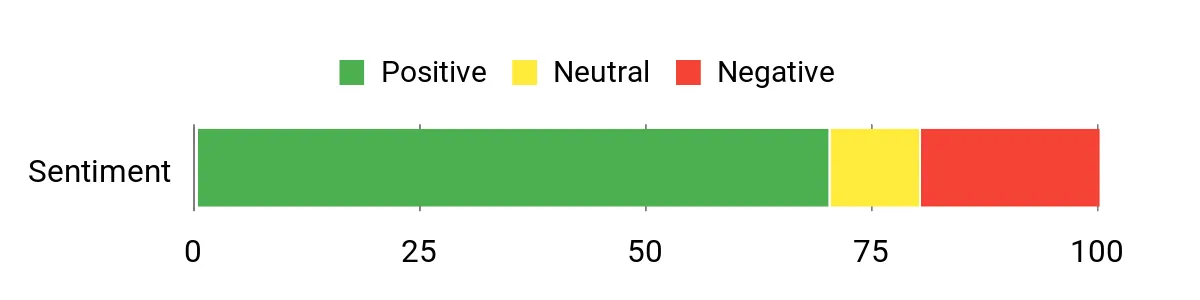

What People Say

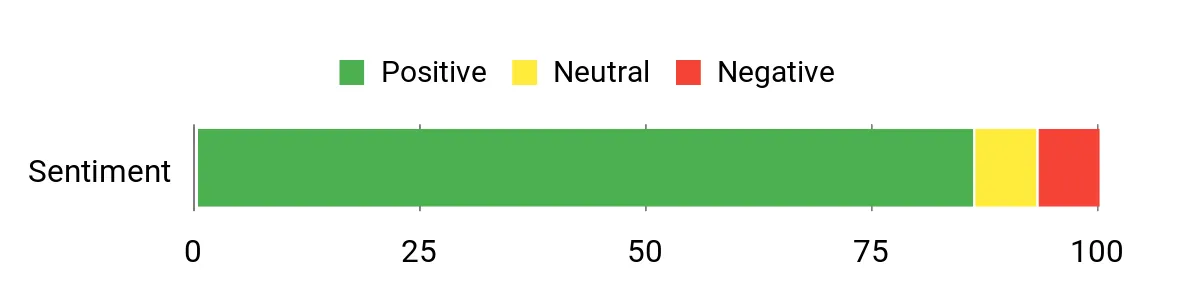

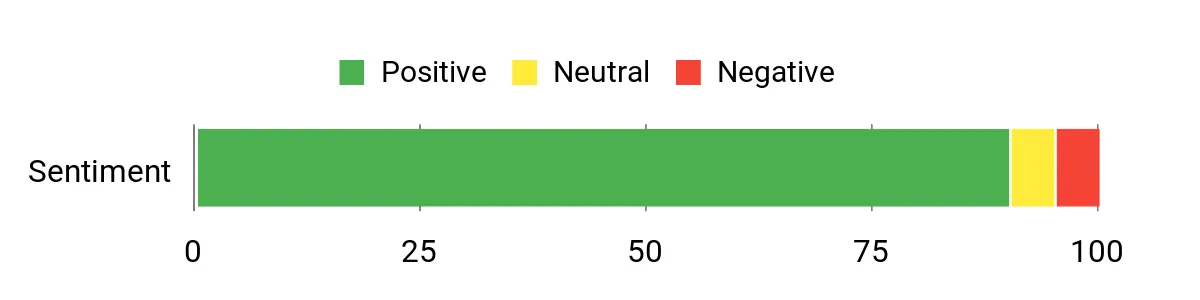

You’ll find most users praise the cutter for raw cutting power, ease of use and the flexibility of 110V/220V operation. People often note clean cuts on common thicknesses and that the pilot arc extends consumable life when cutting dirty metal.

At the same time some buyers report occasional quality control or early failure issues, so experiences vary and replacement parts or support can come into play.

Overall Sentiment: Neutral

Versatility

Versatile enough for hobbyists and light pros, it handles plate cutting, mesh/grid work, marking and some gouging without swapping machines. You’ll appreciate the multiple modes when switching between fabrication and repair tasks.

Durability

Build quality is generally solid for the price and the unit’s compact frame stands up to workshop use, but a minority of users report early faults or consumable wear if the cutter is pushed hard. Expect to keep spare tips on hand and to check fittings after transport.

Key Benefits

- Dual‑voltage flexibility for different outlets and job sites

- Non-touch pilot arc improves starts on painted or rusty surfaces

- Four cutting modes add real versatility for shop projects

- Portable 22 lb design makes it easy to move around

Rating: 4.3 (total: 84+)

You get a compact, user-friendly cutter that’s easy to move around the garage and simple to set up on either 110V or 220V. The large digital display makes dialing in settings straightforward, and it handles common shop tasks like plate cutting and pipe work without a lot of fuss. It’s a solid pick if you want a dependable tool for DIY projects, maintenance, or light fabrication, and keeping a spare tip kit on hand will help avoid downtime.

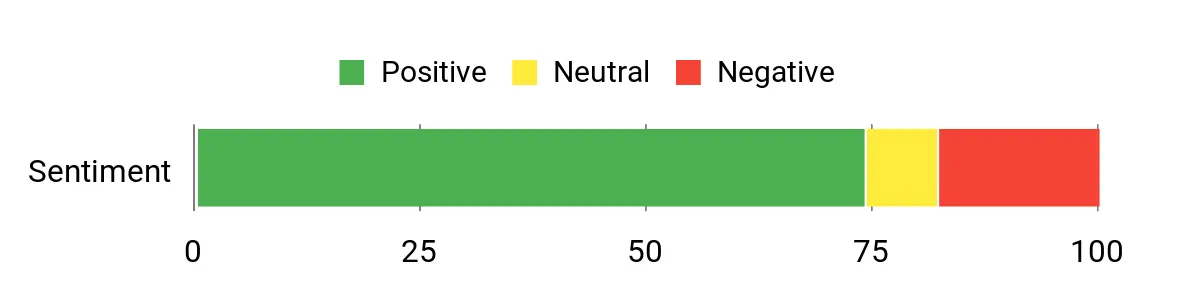

What People Say

Most users like how easy the cutter is to use and move, praising the dual‑voltage capability and clear digital display. People often mention reliable cuts on typical shop materials and that it’s a great fit for hobbyists or weekend fabricators. A subset of buyers report quality control issues or early failures, so experiences can vary and having support or spare parts available helps.

Overall Sentiment: Neutral

Versatility

Handles plate cutting, basic pipe work and general shop repairs well, and the dual‑voltage support means you can switch between garage outlets and a proper 240V circuit when you need more power.

Durability

Generally solid for light to medium use, though a minority of owners report early unit failures or blown components when pushed hard. Plan to replace consumables regularly and check fittings after transport.

Key Benefits

- Dual‑voltage flexibility for more jobsite options

- Large display simplifies setup and adjustments

- Lightweight and portable for small shops or mobile work

- Good performance on common thicknesses like 1/4 inch

Rating: 4.3 (total: 137+)

You get an all‑in‑one machine that lets you switch between welding and cutting without hauling multiple boxes around. The MCT‑520 covers MIG, flux‑core, TIG, stick and a 50A plasma cutter, plus spool gun support for aluminum, so it’s useful whether you’re doing regular shop repairs or a weekend restoration.

Controls and presets are friendly enough that you can get productive quickly, and the unit’s portability makes it easy to move between the garage and a jobsite. If you want one tool that handles a wide range of metalwork tasks, this is a practical choice.

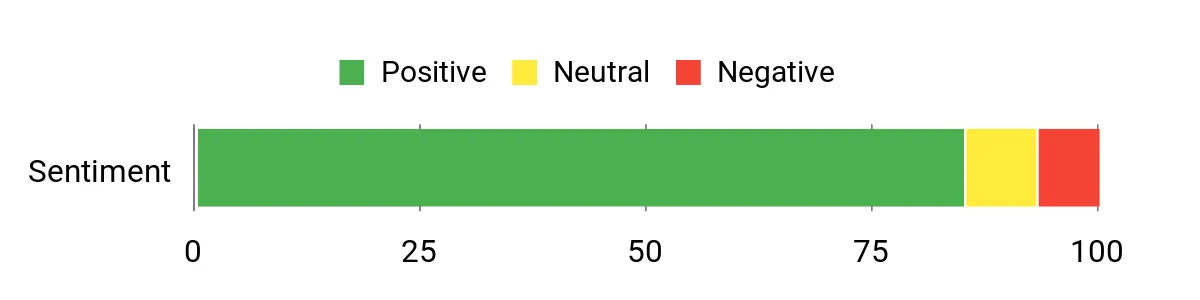

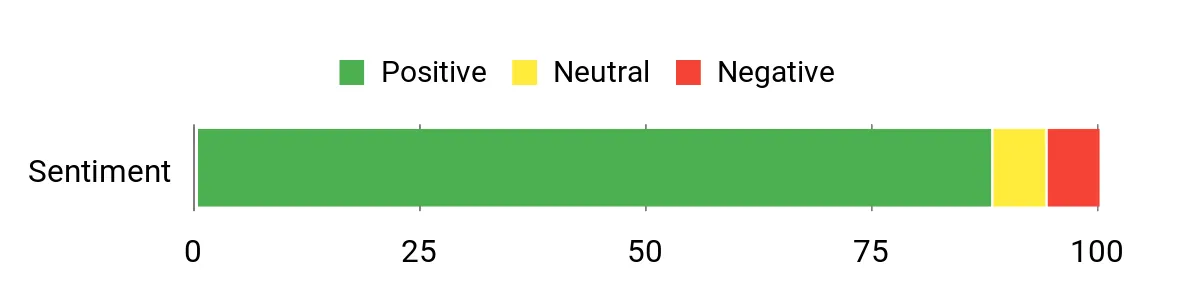

What People Say

Users commonly praise the MCT‑520 for being a true all‑in‑one solution that handles everyday fabrication and occasional heavy tasks. People highlight how easy the settings are to follow and how the plasma cutter and MIG work well for typical shop projects.

A few buyers mention quality quirks like thinner cables or small accessory issues, but many report solid long‑term use after minor tweaks or upgrades.

Overall Sentiment: Positive

Versatility

Extremely versatile for hobbyists and small pros, it switches between six processes and accepts a spool gun, so you can move from bodywork to structural repairs without another machine.

Durability

Overall build feels good for a multifunction unit and many owners report reliable performance over months of use; some users upgrade consumables or cables for heavier duty work to improve longevity.

Key Benefits

- Multi‑process flexibility lets you tackle welding and cutting without extra machines

- Spool gun compatibility makes aluminum work accessible

- Straightforward controls and presets flatten the learning curve

- Portable enough for home workshops and occasional jobsite use

Rating: 4.6 (total: 155+)

You get a compact, punchy cutter that’s easy to move around yet delivers serious cutting power for common shop jobs. It auto‑senses voltage so you can plug into 110V or 220V and get started quickly, and the digital display helps you fine‑tune settings without guesswork. It’s great for everyday maintenance, fabricating brackets and frames, and even occasional heavier work when you need clean, fast cuts. If you want a balance of portability and capability that fits a busy garage or small shop, this model is worth a close look.

What People Say

Buyers often highlight how well the cutter rips through typical shop materials and how simple it is to set up thanks to the digital interface and auto voltage sensing. Many users praise its portability and consistent cuts on 1/4″ plate, while a smaller group reports fitment or connector issues that needed a quick fix.

Overall people appreciate the performance for workshop tasks but recommend keeping spare consumables and checking connections after unboxing.

Overall Sentiment: Positive

Versatility

Handles plate cutting, repair work, and light fabrication comfortably; some users also integrate it into CNC tables with minor adjustments, though it’s primarily aimed at handheld shop work.

Durability

Generally sturdy with a tough finish and reliable operation for routine use, but expect to replace consumables periodically and verify internal connectors if you get a unit that needs a quick tweak.

Key Benefits

- Compact, lightweight design for easy transport and jobsite use

- Digital display and auto voltage sensing simplify setup

- Non‑touch pilot arc improves starts on painted or rusty metal

- Blowback start and robust cutting performance for common thicknesses

Rating: 4.3 (total: 660+)

You get a compact, easy-to-move cutter that works well in a garage or jobsite trailer. The large LED display makes dialing in air pressure and amperage less guesswork, and dual-voltage support means you can use standard outlets or a proper 240V feed when you need more punch.

It’s solid for routine shop tasks like plate cutting, pipe work and quick repairs, and the non-touch pilot arc helps when you’re cutting painted or rusty surfaces. If you want a dependable, straightforward cutter for everyday metalwork, this model hits the sweet spot.

What People Say

Users frequently praise how cleanly it cuts common materials and how straightforward the controls are, especially when running on 220V. Many owners like its portability and how useful the pilot arc is on painted or rusted parts.

At the same time some buyers report occasional reliability or connector issues and note the 110V mode is limited, so experiences vary and a quick check of fittings after unboxing is a good idea.

Overall Sentiment: Neutral

Versatility

Good for everyday fabrication, maintenance and light production work; works nicely for sheet metal, trailer repairs and piping tasks where a handheld cutter is more practical than larger equipment.

Durability

Build feels solid for routine use, though a notable minority report early failures or loose connectors; plan to keep spare consumables and inspect air fittings and plugs during setup.

Key Benefits

- Large LED display simplifies setup and adjustments

- Dual‑voltage flexibility for garage or shop circuits

- Non‑touch pilot arc improves starts on dirty metal

- Portable 19 lb-ish design for easy handling

Rating: 4.3 (total: 903+)

You get a compact, feature‑packed cutter that’s easy to move between the garage and a jobsite. It auto‑senses 110V/220V, offers a clear digital display for quick setup, and the non‑touch pilot arc makes starting on painted or rusty metal less fiddly.

The four dedicated modes cover most shop tasks, so you can switch from sheet metal to grid cutting without swapping tools. It’s a practical choice if you want capability without hauling industrial equipment.

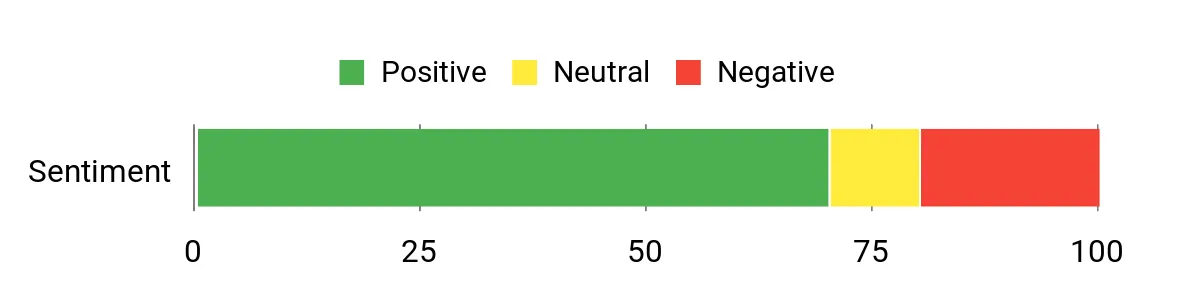

What People Say

Most owners celebrate the cutter’s power and versatility, noting clean cuts and easy setup thanks to the display and auto voltage sensing. People also highlight the pilot arc for cutting painted or rusty pieces and appreciate the portability.

A few users mention occasional quality control hiccups and recommend checking connections and keeping spare consumables on hand.

Overall Sentiment: Positive

Versatility

This unit adapts well to fabrication, repair and artistic metalwork thanks to its dedicated modes; you’ll find it useful for trailer repairs, brackets, mesh work and light gouging without needing separate machines.

Durability

The build feels robust for workshop use and the finish holds up to regular handling, but some buyers report early defects or consumable wear when pushed hard; inspect fittings after unboxing and plan for routine tip replacements.

Key Benefits

- Dual‑voltage flexibility for garage outlets or 240V circuits

- Non‑touch pilot arc for cleaner starts on dirty or painted metal

- 4‑in‑1 modes handle plate, mesh, gouging and marking

- Portable ~22 lb design with a bright, readable display

Rating: 4.8 (total: 16+)

You’ll find this cutter fits nicely in a garage or jobsite trailer thanks to its manageable weight and clear LED interface. It auto‑switches between 110V and 220V so you can use standard outlets for light tasks and a 240V feed when you need more power. The non‑touch pilot arc helps when you’re cutting painted or rusty metal, and the display makes dialing in air pressure and amperage less of a guess.

It’s a practical option for routine repairs, trailer work and general fabrication, though you should expect to keep spare consumables and check fittings after unboxing.

What People Say

You’ll see many buyers praise clean cuts and the straightforward controls, especially when running on 220V. People like the portability and the pilot arc for painted or rusted pieces, but a number of reviewers report occasional connector or reliability issues, so checking connections and having spare tips helps avoid downtime.

Overall Sentiment: Neutral

Versatility

Good for sheet metal, trailer repairs and everyday fabricating tasks; performs best handheld but can handle a range of shop jobs.

Durability

The unit generally holds up under normal shop use, though some owners experience early faults or moisture/connector problems; routine consumable replacement and a quick post‑unbox inspection are recommended.

Key Benefits

- Large LED display for easier setup and adjustments

- Dual‑voltage flexibility for more outlet options

- Non‑touch pilot arc eases starts on dirty metal

- Portable form factor suitable for small shops and jobsite use

Rating: 4.3 (total: 903+)

You get a convenient, all‑in‑one cutter that removes the need to rig a separate air supply for many jobs. The fused design pairs a readable LED display and non‑touch pilot arc with an onboard compressor so you can move between the driveway, garage and jobsite with less setup. It handles routine sheet metal work, trailer repairs and light fabrication with fewer accessories to manage, and the straightforward controls help you get productive quickly.

What People Say

Buyers frequently mention how handy the integrated compressor is for reducing gear and simplifying setup, and many like the clear display and easy controls. People note it cuts common shop materials reliably and that the pilot arc helps with dirty or painted surfaces.

A few reviewers point out the compressor pressure can be limited for heavier tasks and recommend checking consumables availability.

Overall Sentiment: Positive

Versatility

Well suited for everyday fabrication, auto repair and hobby projects where an internal air source and simple controls speed up the work; works best for handheld cutting and light production tasks.

Durability

The unit feels solid for regular shop use, but some users report compressor pressure limits or the need to replace consumables more often; plan to inspect fittings after delivery and keep spare tips handy.

Key Benefits

- Built‑in compressor reduces the need for an external air source

- Large LED display makes setup and adjustments quick

- Non‑touch pilot arc helps with painted or rusty metal

- Portable design suitable for mobile and garage work

Rating: 4.4 (total: 29+)

You’re looking at a true all‑in‑one machine that lets you switch between welding and cutting without hauling separate gear. The MP‑200 handles MIG, flux core, TIG, stick and includes a plasma cutter and spool gun support for aluminum, so it works for bodywork, restorations and classroom learning alike. Controls are approachable, which helps if you’re teaching someone or getting back into welding after a long break. It’s a great option when you want one box that covers most shop tasks and keeps your workspace less cluttered.

What People Say

Most users appreciate how the MP‑200 consolidates welding and cutting tasks into one compact package, praising its ease of setup and how well the MIG and plasma functions handle common shop work. Buyers note it’s forgiving for learners and useful for teaching, though some people swap a few accessories or upgrade cables for heavier duty use. Overall the impression is that it delivers a lot of capability for home shops and hobbyists.

Overall Sentiment: Positive

Versatility

Extremely flexible for weekend fabricators and small shops, covering everything from light structural work and trailer repairs to hobby projects and aluminum with a spool gun.

Durability

Build quality is solid for typical home and hobby usage, but some owners replace thinner cables or tweak accessories for long‑term heavy duty work; routine consumable swaps are expected.

Key Benefits

- Multi‑process capability reduces the need for separate machines

- Spool gun compatibility makes aluminum jobs much easier

- User‑friendly controls help beginners get productive quickly

- Relatively portable for a full‑feature multi‑process unit

Rating: 4.6 (total: 155+)

You get a compact, no‑nonsense cutter that’s easy to move around the shop and capable of clean cuts on common steel thicknesses. It supports 110V and 220V so you can work from a garage outlet or a proper 240V feed, and the non‑touch pilot arc helps when you’re dealing with painted or slightly rusty material.

Whether you’re running a CNC table or doing handheld repairs, this model offers a straightforward interface and reliable performance that makes routine cutting faster and less frustrating.

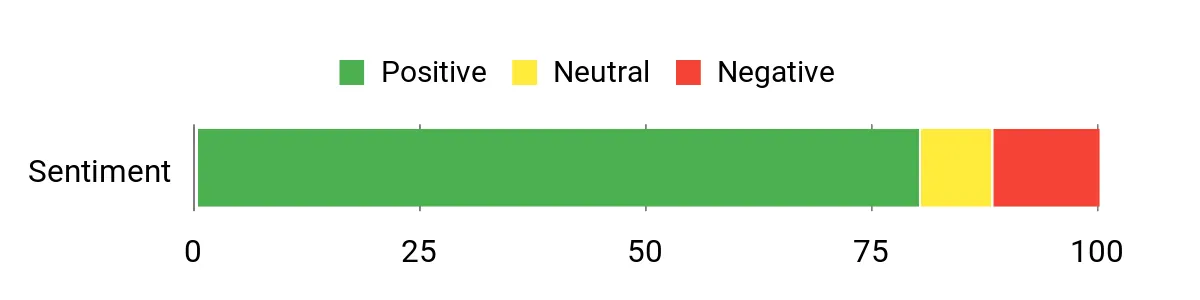

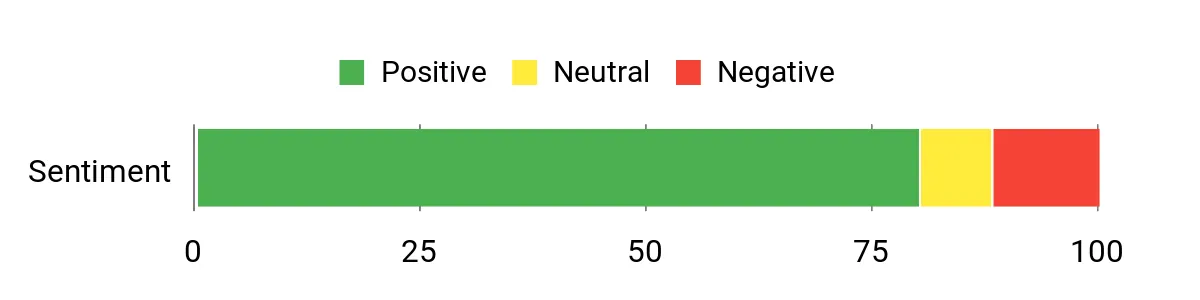

What People Say

Buyers commonly note the unit cuts cleanly through thicker plate and holds up well in daily shop use. People appreciate the clear display and non‑touch start for reducing consumable wear, and several users report success both handheld and installed on CNC tables. A few mention checking grounding and fittings to get the best, most consistent results.

Overall Sentiment: Positive

Versatility

Well suited to both handheld shop work and CNC table setups; you can switch between fabrication, repair and production tasks without changing platforms.

Durability

Build quality feels solid for regular use and many owners report consistent operation over time; maintain consumables and confirm proper grounding to avoid intermittent issues.

Key Benefits

- Strong cutting performance on 3/8″–1/2″ steel

- Non‑touch pilot arc for cleaner starts on dirty surfaces

- Large digital display simplifies adjustments

- Compact and light enough for handheld or CNC use

Rating: 5 (total: 10+)

FAQ

Power And Air Requirements?

You can run many Yeswelder cutters on 110V for light tasks, but you’ll get the best cutting power on 220V when working thicker metal. For air, aim for a stable pressure around 60–90 psi and a compressor that can keep up with your cut times; add a moisture trap or dryer and an auxiliary tank if you want longer continuous cuts.

When you unpack the machine check all fittings and connectors and bleed the air filter before first use to avoid startup headaches.

How Thick Will These Cut?

Most models in this roundup cut 1/4″ easily, while higher‑amp units commonly deliver clean cuts in the 3/8″–9/16″ range and can sever up to about 1″ with multiple passes. For the cleanest edges use 220V, the right air pressure and a steady travel speed, and rely on the non‑touch pilot arc when you’re working on painted or rusty material to reduce consumable wear.

Maintenance And Consumables?

Expect to replace tips, electrodes and nozzles periodically and keep a small spares kit on hand so you don’t sit idle. Regularly drain moisture from the air filter, check torch leads and ground clamp connections, and inspect internal push fittings after transport; if something looks loose or the display doesn’t power up, verify connectors before extensive troubleshooting and contact support if you find obvious factory defects.

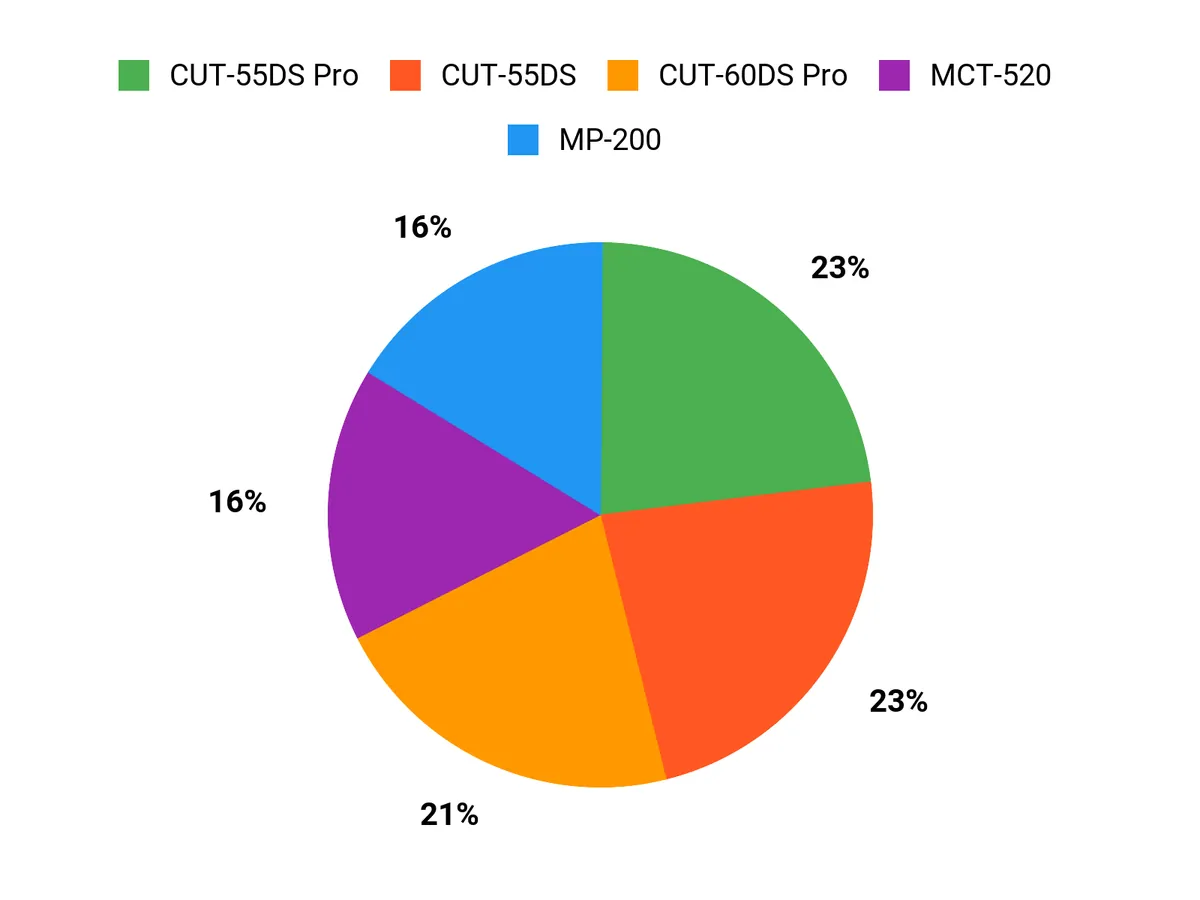

What Buyers Prefer

When choosing between the CUT‑65DS Plus, CUT‑50DS and the MCT‑520 you typically weigh cutting power and dedicated features against portability and multi‑process flexibility. Pick the CUT‑65DS Plus for higher amps and the 4‑in‑1 modes when you need heavier severance, the CUT‑50DS if you want a lighter, easy‑to‑move cutter for everyday shop work, and the MCT‑520 when you prefer one machine that covers MIG, TIG, stick and plasma so you can switch tasks without extra gear.

Wrapping Up

You can use this list to quickly narrow choices based on how and where you work. If you want raw cutting power and versatility, pick a higher‑amp model like the CUT‑65DS variants; if budget matters, the CUT‑50DS delivers solid performance for light projects. Multi‑process machines such as the MCT‑520 or MP‑200 are smart if you want welding plus cutting in one cabinet, while the Fusion model removes the need for an external compressor. Pay attention to voltage requirements, air supply and consumable availability, and plan for regular tip replacements and basic maintenance so the cutter keeps performing.

With the right match to your needs you will cut faster, spend less time on cleanup and open up new projects you might otherwise avoid.

| Product Name | Image | Rating | Power Source | Cutting Amp | Weight |

|---|---|---|---|---|---|

| YESWELDER CUT-65DS PLUS Plasma Cutter |

|

4.3/5 (84 reviews) | Hand Powered | 65 Amp | 22 pounds |

| YESWELDER CUT-50DS Plasma Cutter |

|

4.3/5 (137 reviews) | DC | 50 Amp | 18.08 pounds |

| YESWELDER Multifunctional Welders Combo & Plasma Cutter |

|

4.6/5 (155 reviews) | DC | 50 Amp | 47.3 pounds |

| YESWELDER CUT-60DS PRO Plasma Cutter |

|

4.3/5 (660 reviews) | Power Supply | 60 Amp | 21.4 pounds |

| YESWELDER CUT-55DS PRO NEW Plasma Cutter |

|

4.3/5 (903 reviews) | DC | 55 Amp | 19.41 pounds |

| YESWELDER Plasma Cutter with Built In Air Compressor |

|

4.4/5 (29 reviews) | Hand Powered | 55 Amp | 25 pounds |

| YESWELDER Plasma Cutter Welder Combo |

|

4.6/5 (155 reviews) | DC | N/A | 49.1 pounds |

| YESWELDER CUT-55NHF Plasma Cutter |

|

5.0/5 (10 reviews) | DC | 55 Amp | 20.2 pounds |

| YESWELDER Plasma Cutter, 65Amp 110V/220V |

|

4.8/5 (16 reviews) | Hand Powered | 65 Amp | 22.3 pounds |

This Roundup is reader-supported. When you click through links we may earn a referral commission on qualifying purchases.