You rely on a plasma cutter to make accurate cuts, save time, and keep projects on schedule. This list focuses on machines that deliver on power, reliability, and real-world value so you can pick a tool that matches your workflow, whether you need portable convenience, shop-level duty cycles, or CNC compatibility.

Read on and you’ll know which models are worth your investment and why they might fit your shop or jobsite.

Top Picks

|

Category |

Product |

Score |

|---|---|---|

|

🏆 Best for Heavy-Duty |

96/100 |

|

|

💼 Best for Field Work |

92/100 |

|

|

🚀 Best Portable |

94/100 |

|

|

🎯 Best for CNC |

80/100 |

|

|

💰 Best Budget Multi-Process |

86/100 |

|

|

⭐ Best for Precision |

90/100 |

|

|

🔰 Best All-in-One |

93/100 |

|

|

🎨 Best Combo Welder |

88/100 |

|

|

⚡ Best High-Amp Value |

85/100 |

|

|

🔧 Best for Garage Fabricators |

89/100 |

Selection Criteria

You need a cutter that matches how and where you work, so we weighted factors that matter most to pros. Cutting capacity and duty cycle determine whether a machine can handle daily shop loads or weekend repairs.

Portability, dual-voltage support and whether a machine includes a compressor affect where you can use it and what extra gear you must buy. Consumable cost, ease of use features like pilot arc or drag cutting, and CNC compatibility round out the choices because they influence running cost, cut quality, and how fast you get repeatable results.

You get a workstation-ready plasma cutter that focuses on versatility and uptime. The SYNC version automates torch setup so you spend less time fiddling with consumables and more time cutting. It handles drag, fine, flush and mechanized cutting plus aggressive gouging, so whether you’re doing detailed shop work or heavy metal removal it adapts to the task.

If you want a unit geared toward professional workflows and repeatability, this one aims to reduce setup fuss and keep you moving.

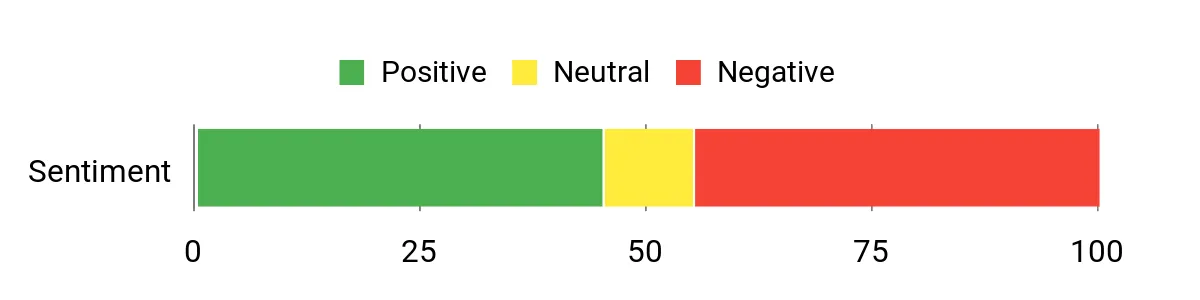

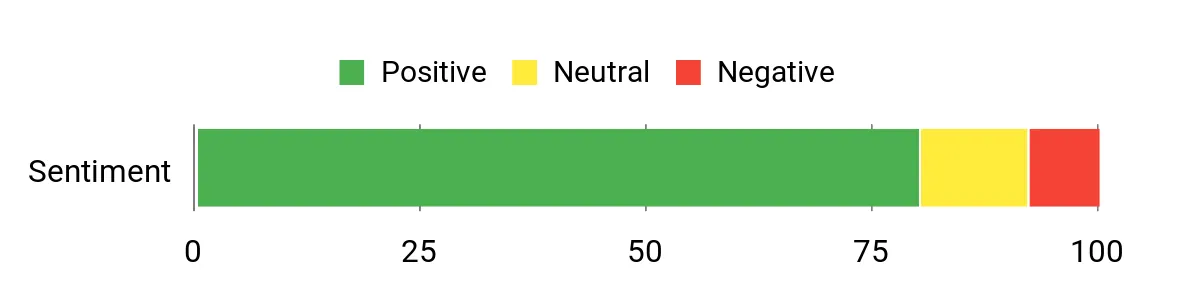

What People Say

Customers commonly highlight the Powermax 45 SYNC’s versatility and the convenience of its sync torch features. People appreciate the longer-lasting cartridge and consistent cut quality across different cut styles, though a small sample of reviewers notes mixed overall satisfaction, so experiences can vary depending on use case and expectations.

Overall Sentiment: Neutral

Situational Benefits

|

Situation |

How It Helps |

|---|---|

|

Shop Production |

Automated setup and durable consumables keep cycle times down and reduce interruptions during repetitive cutting tasks. |

|

On-Site Repairs |

Portable torch options and robust cut modes let you handle quick repairs and patch work without complex reconfiguration. |

|

Heavy Gouging |

Max removal gouging delivers aggressive metal removal when you need to reshape or clean up weld joints fast. |

|

Mechanized Cutting |

Advanced torch communication supports automated tables and portable automation for repeatable, accurate cuts. |

Problem Solving Ability

This unit addresses common shop headaches by cutting setup time, stretching consumable intervals, and offering a range of cut modes so you don’t need separate tools for detail work and heavy removal. The result is fewer interruptions and more consistent results across jobs.

Key Benefits

- Longer consumable life reduces downtime and running cost

- Automated torch communication speeds setup and ensures consistent performance

- Multiple cutting modes cover fine detail, flush cuts and heavy gouging

Rating: 3.0/5 (total: 2+)

You get a compact inverter plasma that balances portability with real cutting power. It runs on 120V or 240V and handles common shop tasks like sheet metal, framing repairs, and light fabrication.

The Spectrum 375 is easy to carry and approachable if you’re newer to plasma, but it also performs well for experienced users who need a reliable, everyday cutter in the shop or out on the ranch. If you plan to cut stainless or heavier plate regularly, plan to run it on 240V and consider an inline filter and longer leads for the best results.

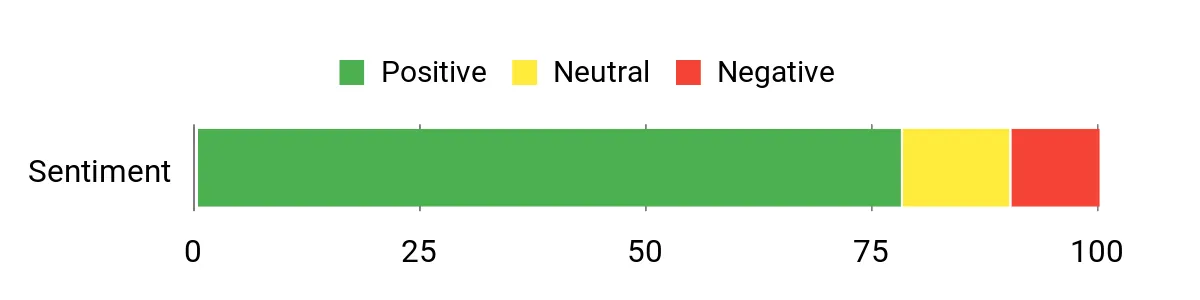

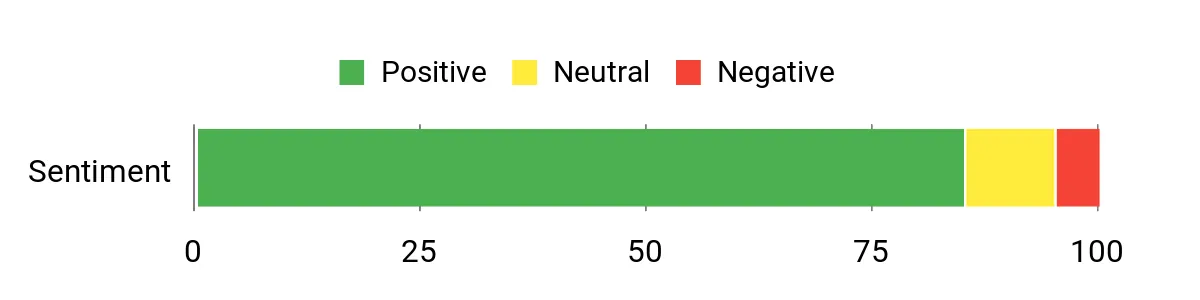

What People Say

Buyers often praise how dependable and versatile this Miller unit is, noting it cuts everything from thin sheet to truck frames when set up properly. People like that it’s lightweight and easy to learn on, though some mention the torch hose stiffness and the need for 240V or accessories like filters and adapters to get optimal performance on thicker or stainless materials.

Overall Sentiment: Positive

Situational Benefits

|

Situation |

How It Helps |

|---|---|

|

Hobby Fabrication |

Lightweight build and simple controls make it easy to learn and take on small projects without a lot of setup. |

|

Mobile Repairs |

Portable inverter design lets you move between job sites and tackle vehicle or farm equipment repairs. |

|

Shop Production |

Reliable cut quality and steady performance keep repetitive tasks moving when you run it on proper 240V power. |

|

Stainless Cutting |

Performs acceptably when dialed in, but benefits from 240V, a good compressor, and an inline filter for cleaner results. |

Problem Solving Ability

This cutter replaces slower methods like cut-off wheels for most shop tasks, gives you a portable option for field repairs, and reduces setup friction with an easy-to-use interface. It doesn’t eliminate the need for proper power and air prep, but once those are in place it reliably tackles a broad range of cutting jobs.

Key Benefits

- Portable inverter design that’s easy to move around your shop or jobsite

- Solid cut quality on a variety of metals for everyday fabrication tasks

- User-friendly operation that helps you get productive quickly

- Proven reliability for long-term shop use

Rating: 4.3/5 (total: 42+)

You get a compact workhorse that’s easy to move and ready to cut as soon as you hook up power and air. The two‑in‑one design means you can switch between high‑power cutting for thicker plate and fine‑cut consumables for detailed work without needing multiple torches.

The Duramax LT torch and 15′ lead stand up to shop use, and the one‑knob interface makes settings straightforward. If you want a portable unit that still gives you clean edges and reliable repeatability, this is a practical choice.

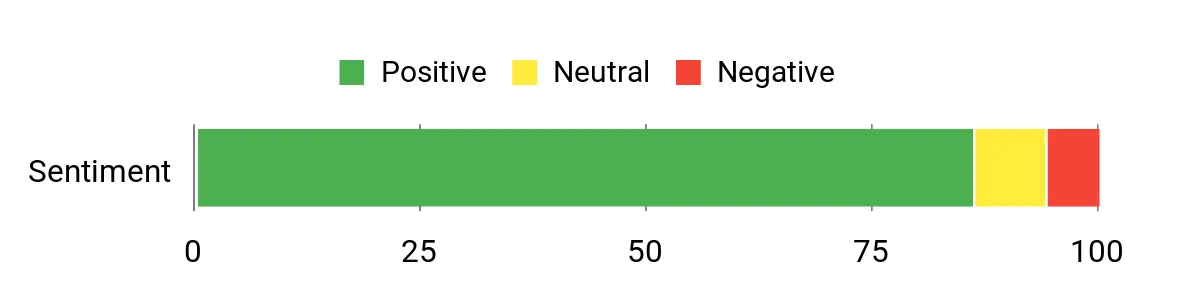

What People Say

You’ll notice most users praise how much this little machine can do for its size, especially the clean cuts with fine consumables and the rugged torch. Many people point out how easy it is to pack up and move between jobs, while a few note that commercial, nonstop use can reveal small durability issues like a water separator leak that may need replacement over time.

Overall Sentiment: Positive

Situational Benefits

|

Situation |

How It Helps |

|---|---|

|

Hobby Projects |

Lightweight portability and simple controls let you set up in a garage or workshop and get cutting with minimal fuss. |

|

Mobile Work |

Auto‑voltage support and compact size make it easy to take on-site and run from 120V or 240V circuits as needed. |

|

Detail Cutting |

Fine Cut consumables deliver cleaner edges and reduced dross, so you spend less time grinding and finishing. |

|

Small Shop Production |

Durable torch lead and simple interface keep repetitive tasks efficient while remaining easy to train others on. |

Problem Solving Ability

This unit solves the need for a true portable cutter that still delivers shop‑level cut quality, reducing the number of tools you need and cutting setup time for mixed tasks.

Key Benefits

- Two‑in‑one capability for both thick cuts and fine detail

- Compact, lightweight and easy to transport

- Duramax LT torch built for impact and heat resistance

- Simple one‑knob interface for fast setup

Rating: 4.5/5 (total: 97+)

You get a CNC-ready cutter that’s built for table work and portable automation. The 100 amp output gives you the headroom to tackle thicker plates while the blowback start reduces high-frequency interference, which matters if you’re running sensitive electronics nearby.

It’s a heavier unit at about 60 pounds, so plan for a stable workspace, and the combo set approach makes it straightforward to integrate into a small production line. If you want a machine aimed at repeatable cuts and reliable vendor support, this one fits a shop that leans on mechanized workflows.

What People Say

You’ll notice users appreciate the CNC compatibility and the reliable support from the maker, which helps when integrating the unit into a workflow. People also point out that the cutter performs well for mechanized tasks, though a few buyers expect industrial-level polish given its ambitions.

Overall Sentiment: Neutral

Situational Benefits

|

Situation |

How It Helps |

|---|---|

|

CNC Table Work |

Designed to plug into mechanized setups so you get precise, repeatable cuts without extra retrofitting. |

|

Small Production Runs |

100A capacity lets you cut through thicker stock faster, keeping cycle times down for short runs. |

|

Sensitive Electronics Nearby |

Blowback start minimizes high-frequency interference that can upset nearby controls or devices. |

|

Integration & Support |

Responsive technical help makes onboarding and troubleshooting faster when you bring it into a new shop. |

Problem Solving Ability

This cutter solves the need for repeatable, mechanized cutting by combining CNC-ready connectivity with a high-output torch and a start method that’s kinder to nearby electronics. The practical upside is less fiddling with the torch, fewer integration headaches, and quicker recovery when issues arise thanks to responsive support.

Key Benefits

- CNC and table-ready controls for repeatable automated cutting

- 100A output handles heavier plate and faster severance

- Blowback start reduces HF interference near electronics

- Responsive technical support that eases setup and troubleshooting

Rating: 3.7/5 (total: 2+)

If you want a portable cutter that keeps setup simple, this YESWELDER model is built around convenience. The LED panel makes adjustments obvious, the non-touch pilot arc helps you start cleanly on painted or rusty metal, and the built-in compressor option means fewer accessories to haul.

It’s well suited to hobbyists and small shops who need a flexible, multi-task tool you can move around without fuss.

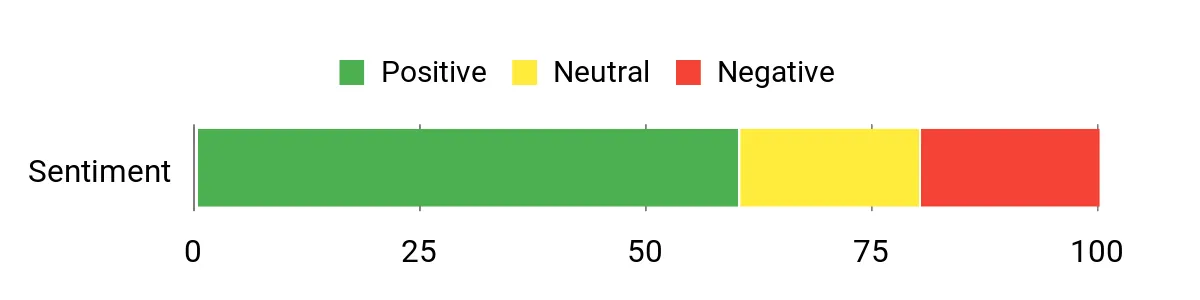

What People Say

Most users like how straightforward this unit is to set up and operate, especially the LED controls and stable arc. People appreciate the portability and multi‑function capability for garage projects and light shop work, while a few note that consumable availability and compressor pressure can affect performance in some setups.

Overall Sentiment: Positive

Situational Benefits

|

Situation |

How It Helps |

|---|---|

|

Beginner Projects |

Simple controls and a forgiving pilot arc make it easier to get clean cuts while you learn the ropes. |

|

Garage Fabrication |

Built-in compressor and compact size reduce the gear you need to move between tasks in a small shop. |

|

Mobile Repair |

Dual‑voltage support and portability let you respond to on‑site repairs without hunting for special equipment. |

|

Mixed Welding/Cutting |

Multi‑process capability and clear digital controls let you switch tasks quickly and keep work flowing. |

Problem Solving Ability

This cutter solves the common need for a compact, easy-to-use machine that reduces setup friction and handles a range of materials, so you spend less time prepping and more time cutting or welding.

Key Benefits

- Built-in compressor for simpler setup and fewer external parts to manage

- Clear LED display that makes settings easy to read and change

- Non-touch pilot arc handles painted or rusty surfaces more reliably

- Dual-voltage flexibility lets you work from 110V or 220V outlets

Rating: 4.4/5 (total: 29+)

You get a surprisingly capable cutter that feels built for garages and small shops that want precise, repeatable cuts. It’s drag‑cut ready for clean edges on thin sheet, but the 63A output also handles heavier gauge work when you run 240V.

The LED controls and front regulator make setup faster, and the torch ergonomics help when you’re doing longer runs. If you want a unit that bridges hobbyist convenience and shop‑level accuracy, this one is a solid match.

What People Say

Most users appreciate the clean cuts and the intuitive controls, noting it’s beginner friendly without feeling underpowered. People like the drag‑cut feature and the comfortable torch, and many say it’s easy to integrate into small production or art projects. A few customers remind you to plan for a good air supply since there’s no built‑in compressor.

Overall Sentiment: Positive

Situational Benefits

|

Situation |

How It Helps |

|---|---|

|

CNC Table Work |

CNC connectors and stable arc give repeatable cuts, so you spend less time calibrating and more time running jobs. |

|

Garage Fabrication |

Dual‑voltage and a long torch lead let you move around the shop and handle a range of frame and repair tasks. |

|

Art & Signmaking |

Drag‑cut capability produces smoother edges on thin sheet and stencils, which reduces finish work and cleanup. |

|

Light Production Runs |

63A output and easy setup keep cycle times predictable for short runs without needing industrial gear. |

Problem Solving Ability

This cutter addresses the need for accurate, repeatable cuts in a compact package by combining drag‑cut support, clear controls and CNC readiness. The practical outcome is less fiddling during setup, fewer trimmed parts, and smoother integration into small mechanized workflows.

Key Benefits

- Drag‑cut support for steadier, cleaner freehand cuts

- Dual‑voltage flexibility so you can work in more locations

- Bright LED interface and front regulator speed setup

- Ergonomic torch and long lead for comfortable, longer sessions

Rating: 4.7/5 (total: 16+)

You get a thoughtfully packed machine that reduces gear and gets you cutting faster. The built‑in compressor removes one external dependency, the non‑touch pilot arc and drag‑cut setup make freehand and painted metal work easier, and the LED panel simplifies adjustments.

It shines when you feed it solid power and an appropriate duty cycle; if you plan heavy continuous work you’ll want to consider how the internal compressor affects runtime. For garage pros and small shops who want a compact, capable cutter with fewer external parts, this one is a strong contender.

What People Say

Users commonly praise how convenient the built‑in compressor makes setup and how clean the cuts can be when the unit is properly powered. Customers also call out the intuitive LED controls and the smooth drag‑cut performance.

A recurring practical note is that the internal compressor draws a lot of power at higher amps, so pairing the machine with the right supply or an external compressor improves consistency.

Overall Sentiment: Positive

Situational Benefits

|

Situation |

How It Helps |

|---|---|

|

Garage Setup |

Built‑in compressor means fewer separate tools to position and plug in, so you can start cutting with less prep. |

|

Stainless Work |

Higher amperage and stable arc give cleaner edges on stainless when you run on a robust circuit. |

|

Portable Jobs |

Compact footprint and onboard air let you move between sites without hauling a separate compressor for light to medium tasks. |

|

Long Runs |

Using an external compressor or a dedicated 240V feed prevents voltage sag and keeps cutting steady during extended sessions. |

Problem Solving Ability

This cutter solves the common friction of matching air and power by including a compressor and clear controls, making setup faster and reducing tool juggling. The tradeoff is power demand at higher amps, which you can mitigate with a dedicated circuit or external compressor to maintain consistent cuts.

Key Benefits

- Built‑in air compressor reduces setup complexity and gear to manage

- Non‑touch pilot arc and drag‑cut deliver cleaner starts and smoother freehand cuts

- App‑style LED panel and clear controls speed configuration and troubleshooting

- Solid performance on stainless and mild steel when supplied with adequate power

Rating: 4.9/5 (total: 18+)

You get a multi‑tool that replaces several standalone machines and lives comfortably in a garage or small shop. The plasma cutter handles routine fabrication and rusted metal with its pilot arc, while the TIG and stick modes let you switch to welding tasks without swapping gear. It’s approachable for hobbyists but stout enough for repeated use, provided you run it on 240V for heavier work.

If you want one machine that covers cutting and multiple welding styles, this is a practical option to streamline your bench.

What People Say

Users frequently praise the machine’s versatility and how it covers both cutting and welding needs in a single unit. Many note reliable performance over years of use and that the TIG/stick functions are solid for non‑industrial work.

Common practical notes mention needing 240V for best results and that some accessories like a longer ground cable or a foot pedal improve usability.

Overall Sentiment: Positive

Situational Benefits

|

Situation |

How It Helps |

|---|---|

|

Home Shop |

Combines cutting and welding so you can handle restoration, fabrication and small builds without multiple boxes cluttering your bench. |

|

Field Repairs |

Portable enough to bring to a job and versatile enough to switch between cutting and welding tasks on the fly. |

|

Mixed Fabrication |

Switching between TIG, stick and plasma lets you finish parts end‑to‑end without waiting on different tools or shops. |

|

Long‑Term Projects |

Durable construction and reliable performance over years mean you get sustained value for recurring maintenance and builds. |

Problem Solving Ability

This combo unit addresses limited shop space and the hassle of buying multiple machines by offering capable cutting plus two welding modes in one chassis. It reduces gear switching and helps you move from cut to weld quickly, though peak performance depends on proper power and a few useful accessories.

Key Benefits

- Three tools in one package — plasma, TIG and stick — so you carry less equipment

- Capable clean cut performance up to 5/8″ for many shop and farm tasks

- Proven long‑term reliability for home workshops and mobile repairs

- Welding modes give flexibility for fabrication and repair without extra machines

Rating: 4.4/5 (total: 1076+)

You’re looking at a feature‑packed cutter that brings surprising capacity to a compact package. It runs on 110/220V, offers a non‑touch pilot arc for cutting painted or rusty metal, and the big digital display makes dialing settings simple. For art projects, hobby fabrication or occasional shop work it gives you real punch without being cumbersome, though you’ll want to practice thin‑metal technique and ensure a steady air supply for best results.

What People Say

Users often highlight how much cutting power this little box delivers and praise the pilot arc and readable display. Many note it’s a great value for occasional and hobby use, but some recommend practicing technique for thin material and ensuring proper air and power to avoid inconsistencies.

Overall Sentiment: Positive

Situational Benefits

|

Situation |

How It Helps |

|---|---|

|

Art & Detail Work |

Pilot arc and steady controls let you focus on curves and stencils without the torch snagging on painted surfaces. |

|

Home Workshop |

Dual‑voltage support and compact size make it easy to move around the bench and plug into common circuits. |

|

Light Fabrication |

High amp output speeds through thicker plates for repairs and structural pieces that typical hobby cutters struggle with. |

|

Learning & Practice |

Clear display and adjustable settings help you experiment and improve technique without a steep learning curve. |

Problem Solving Ability

This cutter solves the gap between small hobby units and bulkier industrial gear by offering high amperage, a forgiving pilot arc, and easy controls, so you can tackle a wider range of tasks without buying multiple machines.

Key Benefits

- High 75A capacity handles thicker materials that smaller hobby units struggle with

- Non‑touch pilot arc makes starting on painted or rusty surfaces easier

- Dual‑voltage flexibility lets you use standard outlets or 220V for full power

- Large digital display and controls are easy to read and adjust while working

Rating: 4.4/5 (total: 71+)

You get a workhorse that sits between hobby gear and heavier industrial units. It’s built to give clean, repeatable cuts on mild steel and stainless while still being portable enough for a garage or small shop. The drag‑cut feature and non‑touch pilot arc make freehand and painted surface work easier, and the long torch lead keeps you flexible around a bench or table.

Run it on 240V when you need top performance, and plan for a solid air supply to get the best cut quality and duty cycle.

What People Say

Users commonly call out how fast and clean this unit cuts for its size, and many appreciate the long torch lead and comfortable handle. People also note it needs a good air supply and a proper 240V feed to perform at its best. A few reviewers mention small practical annoyances like a short ground cable or the need for extra air drying on continuous runs.

Overall Sentiment: Positive

Situational Benefits

|

Situation |

How It Helps |

|---|---|

|

Garage Fabrication |

Dual‑voltage and a compact footprint let you move it around the bench and tackle frame work, repairs, and medium plate without hauling bigger gear. |

|

Freehand Cutting |

Drag‑cut support and the long torch lead let you rest the torch and maintain a steady path for smoother edges and less burr. |

|

Short Production Runs |

Consistent arc and predictable cuts reduce rework on small batches, keeping cycle times reasonable without industrial investment. |

|

On‑Site Repairs |

Portable weight and durable construction make it easy to bring to a jobsite for quick patching and maintenance tasks. |

Problem Solving Ability

This cutter solves the common need for a versatile, shop‑capable plasma unit that doesn’t require industrial space. It reduces finishing work through cleaner cuts and speeds up small production or repair jobs, though you’ll want proper air management and a strong power supply to avoid interruptions.

Key Benefits

- Drag‑cut capability for smoother freehand edges and fewer finish passes

- Dual‑voltage flexibility so you can use common circuits or full 240V power

- Generous torch lead and ergonomic handle reduce fatigue during longer runs

- Capable clean and severance cuts for a wide range of shop tasks

Rating: 4.5/5 (total: 53+)

FAQ

What Power And Air Do I Need

You should match the machine to the circuits and compressor you actually have. Many compact units run on 120V but give their best performance on 240V, so plan for a dedicated circuit if you expect sustained work; also avoid long extension cords that cause voltage sag.

For air, check the manufacturer’s spec, but most mid‑range cutters expect stable pressure and clean, dry air—using an inline dryer and water separator keeps the torch happy and consumables lasting longer.

How Do Consumables And Maintenance Impact Use

Consumables are the ongoing cost and they directly affect cut quality, so keep a small stock of electrodes, nozzles and shields and check them before long jobs. Regularly inspect the torch lead, fittings and filters, replace worn parts, and use recommended cartridges or tips to avoid blowback or poor pierces. A little routine care—cleaning connections and using a proper air filter—saves you downtime and gives more consistent cuts.

Which Cutter Should You Choose For Your Shop

Decide whether you need portability or long duty cycles and prioritize features that matter to your work, such as drag cut for stencil and sheet work, pilot arc for painted or rusty surfaces, or CNC compatibility for mechanized tables. If you move between jobs, choose a lighter inverter or a model with built‑in compressor for fewer accessories, but if you run long production shifts pick a unit with a higher duty cycle and plan for proper power and air infrastructure.

Always factor in serviceability and spare part availability so you can get back to cutting quickly.

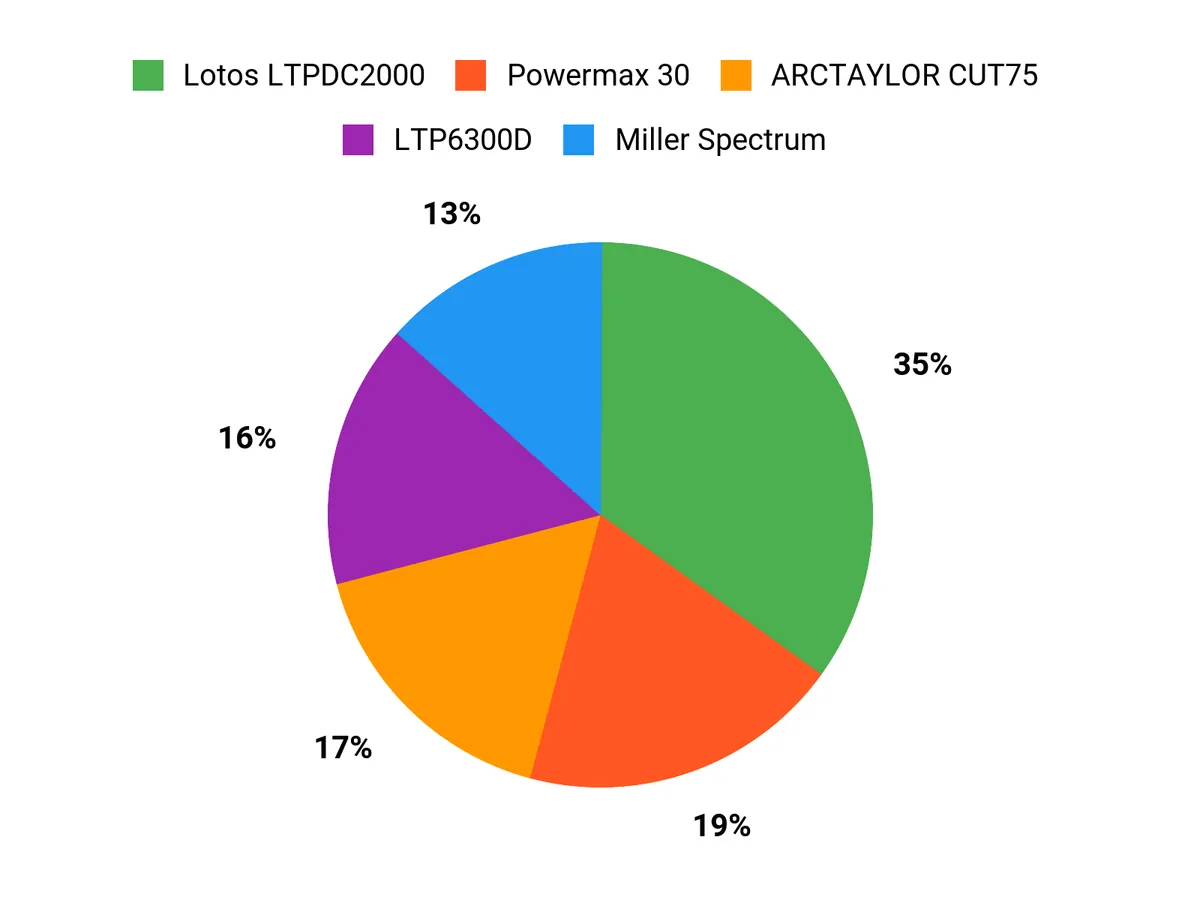

What Buyers Prefer

When you choose between the Powermax 45, Miller Spectrum and Powermax 30, buyers usually prioritize cutting power and duty cycle for heavy shop work, portability for on‑site jobs, or a balance of reliability and ease of use. You’ll lean to the Powermax 45 for sustained, aggressive cuts, the Powermax 30 for lightweight portability and fine detail, and the Miller Spectrum when you want a dependable middle ground that’s easy to carry and performs well on common shop tasks.

Wrapping Up

Choosing the right plasma cutter saves you time, reduces scrap, and lowers ongoing costs from consumables and downtime. If you work long shifts on thick steel, prioritize machines with higher duty cycles and robust torches like the Powermax 45. If you need portability without sacrificing cut quality, the Powermax 30 is purpose-built for that tradeoff. For shop owners who want fewer accessories to manage, units with built-in compressors such as the LTP5600CD simplify setup.

Match the cutter to your typical material thickness, power availability and whether you need CNC or multi-process capability, and you’ll pick a machine that pays back its cost in speed and reliability.

| Product Name | Image | Rating | Cutting Capacity | Power Source | Weight | Special Highlights |

|---|---|---|---|---|---|---|

| Hypertherm Powermax 45 SYNC Plasma Cutter w/ Handheld Torch |

|

3.0/5 (2 reviews) | Up to 5/8 in thick materials | AC | N/A |

|

| Miller Electric 907529 Plasma Cutter, Inverter, Spectrum 375 |

|

4.3/5 (N/A reviews) | Up to 3/8 in thick materials at 10 IPM | 120/240V AC | 33.6 lbs |

|

| Hypertherm Powermax 30 XP Plasma Cutter |

|

4.5/5 (97 reviews) | Up to 5/8 in thick materials | 120/240V AC | N/A |

|

| PowerPlasma 102i CNC Plasma Cutter |

|

3.7/5 (2 reviews) | N/A | AC | 60 lbs |

|

| YESWELDER Plasma Cutter with Built-In Air Compressor |

|

4.4/5 (29 reviews) | 55 Amps, maximum thickness N/A | Dual Voltage 110/220V | 25 lbs |

|

| LTP6300DCNC | 63A CNC-Enabled Plasma Cutter |

|

4.7/5 (16 reviews) | 3/4 in clean cut, 1 in severance cut | AC, Dual Voltage 110/220V | 22 lbs |

|

This Roundup is reader-supported. When you click through links we may earn a referral commission on qualifying purchases.