The .030 Flux Core Welding Wire is designed for efficiency and strength, featuring durable ABS plastic construction and a copper-coated mild steel formulation. This wire excels in outdoor conditions, minimizing spatter while ensuring consistent welds. With a higher manganese and silicon content, it enhances heat management, which reduces warping risks. Its efficient spool design promotes easy handling. Understanding its specifications and performance can help users determine if it fits their needs—let’s explore its applications further.

Key Takeaways

- The .030 diameter flux core welding wire offers strong, consistent welds with minimal spatter, ensuring high-quality results.

- Made from durable ABS plastic and copper-coated mild steel, this wire is designed for longevity and reliable performance.

- Ideal for outdoor projects and windy environments, it excels in fabricating metal structures and repairing equipment.

- The spool design aids in efficient handling, making it user-friendly for both single and multi-pass welds.

- With higher manganese and silicon levels, it enhances heat management and reduces post-weld cleanup needs.

Product Features and Specifications

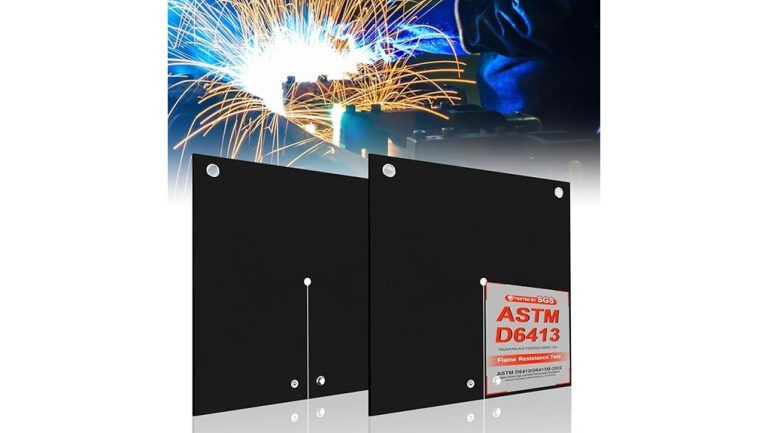

When considering the Flux Core Welding Wire .030, E71T-GS, it is important to note its well-defined specifications and features that cater to various welding needs.

The wire has a diameter of .030 inches (0.8mm) and comes in a 10-pound (4.5kg) spool, designed from strong ABS plastic for product durability.

With a diameter of .030 inches and a durable ABS plastic spool, this 10-pound wire is built for longevity.

This copper-coated mild steel GMAW (MIG) wire is ideal for both single and multi-pass welds, making it versatile for different applications.

With its compatibility for 100% CO2 or a CO2/Argon mix, the spool design guarantees ease of use, promoting efficient handling while welding outdoors or in challenging conditions.

Welding Performance and Characteristics

Flux Core Welding Wire .030, E71T-GS excels in performance, showcasing characteristics that make it a reliable choice for various welding tasks.

Its design promotes welding efficiency, allowing users to achieve strong, consistent welds with minimal spatter.

The wire’s composition, featuring higher manganese and silicon levels, enhances heat management, reducing the risk of warping and ensuring stability during operation.

This results in a smoother weld bead that often requires little to no post-weld cleanup.

Suitable for both single and multi-pass welds, this wire adapts well to different environments, making it an excellent option for diverse applications and conditions.

Recommended Applications and Use Cases

Welding enthusiasts and professionals alike will find the Flux Core Welding Wire .030, E71T-GS to be an outstanding choice for a variety of applications.

This versatile wire excels in outdoor projects, where conditions may be less than ideal. Recommended techniques for peak use include:

- Tack welding in windy environments, where shielding gas may dissipate.

- Fabricating metal structures, ensuring durable joins with minimal spatter.

- Repairing equipment exposed to the elements, providing reliable results.

With its low cleanup needs and high performance, this wire empowers users to tackle demanding jobs confidently, releasing the freedom to create and innovate in their welding endeavors.

Frequently Asked Questions

Is This Welding Wire Suitable for Beginners?

This welding wire is suitable for beginners, offering user-friendly characteristics. Beginner tips include practicing welding techniques that minimize spatter, leading to smoother results. Its performance enhances confidence, making it an excellent choice for novice welders.

How Does This Wire Perform in Windy Conditions?

In windy conditions, this wire excels, allowing outdoor projects to unfold seamlessly. Its unique welding techniques combat drafts effectively, ensuring strong, clean welds. Welders appreciate the freedom to create without the constraints of adverse weather.

What Is the Shelf Life of the Welding Wire?

The shelf life of welding wire is influenced by storage conditions. Proper wire storage tips include keeping it dry, away from moisture, and in a controlled environment to maximize longevity and maintain peak performance during welding projects.

Can This Wire Be Used on Aluminum Materials?

This wire is not suitable for aluminum materials, as its composition and welding techniques are designed specifically for mild steel. Alternative wires designed for aluminum compatibility should be considered for effective results in aluminum welding.

Is There a Difference Between Flux Core and Solid MIG Wire?

Like choosing between a sturdy bridge and a flexible rope, flux core offers advantages in outdoor conditions, while solid wire faces disadvantages in drafts. Each option caters to specific needs, empowering welders in their craft.

Conclusion

In summary, the .030 Flux Core Welding Wire stands out for its robust construction and reliable performance, making it an excellent choice for a variety of welding applications. With its copper-coated mild steel formulation and efficient spool design, users can expect strong welds with minimal spatter. Ideal for outdoor environments, this wire effectively manages heat, reducing warping risks. For both enthusiasts and professionals, it delivers quality results that resonate like a well-tuned engine, ensuring satisfaction with every project.