The Mig Welding Contact Tips 186406 are designed for peak performance, featuring a .035″ diameter that enhances welding efficiency and stability. With 30 durable pieces per pack, these tips guarantee compatibility with popular welder models like Miller and Hobart. Their precision design minimizes spatter, promoting smooth operation and consistent results. Regular maintenance, including timely replacements, plays an essential role in their longevity. Understanding their key features can further enhance your welding experience.

Key Takeaways

- The Mig Welding Contact Tips 186406 enhance welding efficiency with a .035″ diameter for optimal performance in various applications.

- These tips are compatible with popular welder models, including Miller Spoolmate and Hobart Spoolgun, ensuring versatility.

- Constructed from high-quality materials, they offer durability and consistent results while minimizing spatter and improving arc stability.

- Regular maintenance, such as cleaning and timely replacement, ensures prolonged lifespan and optimal performance of the contact tips.

- Users report increased productivity and confidence due to the reliable performance and easy maintenance of these contact tips.

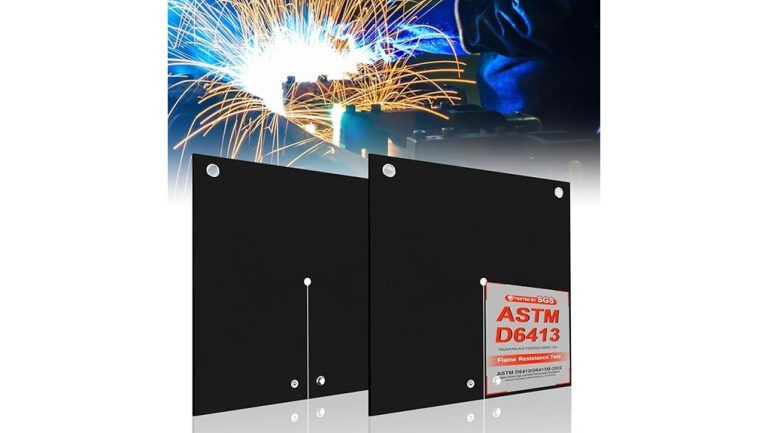

Overview of Mig Welding Contact Tips 186406

The Mig Welding Contact Tips 186406 serve as vital components for achieving ideal welding performance.

Designed with a .035″ diameter, these premium quality tips enhance welding efficiency through their robust construction.

With a pack containing 30 pieces, users can expect durability and reliability during high-demand projects.

Effective tip maintenance is important; regularly checking for wear and replacing tips as needed guarantees optimal performance.

These contact tips facilitate smooth arc stability, allowing welders to focus on their craft with confidence.

Compatibility With Welder Models

When selecting the right contact tips for a welding project, compatibility with specific welder models becomes essential for peak performance. The Mig Welding Contact Tips 186406 are designed to work seamlessly with various models, ensuring maximum functionality. Here’s a quick reference table for compatibility:

| Welder Model | Type |

|---|---|

| Miller Spoolmate | 100, 200, 3035, 185 |

| Hobart Spoolgun | DP-3035, 100, 125, 125 Ez, 130, 140, 190, 210MVP |

| Additional Models | TREK 180, Hobart Beta-MIG 1800, Auto Arc Toolmate 100, IronMan 230 |

For effective performance, follow usage tips and maintenance advice tailored to your specific model.

Key Features and Benefits

Designed to enhance welding efficiency, the Mig Welding Contact Tips 186406 offer several key features and benefits that make them a valuable addition to any welder’s toolkit.

These tips are engineered for peak welding performance, ensuring consistent and reliable results.

- Durability Benefits: Constructed from high-quality materials, they withstand wear and tear, prolonging their lifespan.

- Efficient Design: Their precision design minimizes spatter and improves arc stability, enhancing overall productivity.

- Compatibility: These tips fit a wide range of welder models, providing versatility for various welding applications.

Together, these features contribute to superior performance and reliability in welding tasks.

Frequently Asked Questions

What Materials Are Best Suited for Use With These Contact Tips?

The contact tips are best suited for welding steel alloys and copper alloys. Their high-quality construction guarantees efficient welding performance, making them ideal for those seeking reliable and durable solutions in metal fabrication and repair.

How Often Should I Replace the Contact Tips During Use?

Replacement frequency for contact tips depends on usage intensity and tip wear. Frequent welders may need replacements every few hours, while occasional users could extend this to weeks. Regular inspection guarantees ideal performance and longevity of welding equipment.

Can I Use These Tips for Aluminum Welding?

Aluminum welding with these contact tips is possible, but users should note that contact tip durability may vary. Selecting appropriate tips enhances performance, ensuring successful welding results while maintaining efficiency and reliability in projects.

What Is the Warranty Period for These Contact Tips?

The warranty coverage for these contact tips reflects confidence in their durability, akin to a sturdy bridge enduring the test of time. Customers can expect reliable performance, ensuring freedom from concerns about potential defects or failures.

Are These Tips Compatible With Non-Listed Welder Models?

The tips may encounter compatibility issues with non-listed alternative models. Users should verify fitment to guarantee peak performance, avoiding potential inefficiencies that arise from mismatched equipment, ultimately liberating their welding experience through informed choices.

Conclusion

To summarize, the Mig Welding Contact Tips 186406 offer a reliable solution for welders seeking efficiency and precision. While some may doubt their longevity with regular use, proper maintenance can greatly extend their lifespan, ensuring consistent performance. With a .035″ diameter and compatibility with major welder brands, these tips are designed to minimize spatter and enhance stability. Investing in these contact tips not only improves your welding results but also supports your overall project success.