The Mild Steel TIG Welding Rod ER70S-6 stands out in the welding industry for its quality and performance. Composed of low alloy steel, this rod features high manganese and silicon content, which aids in deoxidization and results in smooth weld beads. With a diameter range from 1/16″ to 3/32″ and excellent usability for applications in automotive and shipbuilding, it caters to both beginners and seasoned professionals. Its impressive customer rating of 4.7 stars indicates a strong reputation, yet specifics about its performance in various conditions warrant further exploration.

Key Takeaways

- The ER70S-6 welding rod is made from low alloy steel, enhancing deoxidization for improved weld quality and reliability.

- It performs well in various welding techniques, making it suitable for automotive, shipbuilding, and machine engineering applications.

- Customers report smooth weld beads and minimal cleanup, contributing to a high satisfaction rating of 4.7 out of 5 stars.

- The product comes with a 30-day return policy and a 2-year warranty, ensuring buyer confidence and support.

- Packaging is designed to prevent moisture absorption, ensuring the rods remain effective and durable over time.

Product Features and Specifications

The Mild Steel TIG Welding Rod ER70S-6 stands out as a reliable choice for those engaging in various welding projects.

The Mild Steel TIG Welding Rod ER70S-6 is a dependable option for all your welding needs.

Its material composition includes low alloy steel, enriched with high levels of manganese and silicon, which enhances deoxidization.

This welding rod, measuring 3/32″ x 16″ (2.4mm x 406.4mm) and weighing 5LB, supports diverse welding techniques.

Significantly, it functions effectively with 100% CO2 shielding gas, allowing for smoother weld beads and minimal cleanup.

With packaging designed to prevent moisture absorption, the rod guarantees durability and usability, catering to both novice and experienced welders seeking quality and efficiency in their tasks.

Performance and Applications

Building on the robust features of the Mild Steel TIG Welding Rod ER70S-6, its performance in various applications showcases its versatility and effectiveness.

This welding rod excels with multiple welding techniques, making it compatible with a range of materials, including low alloy and mild steel. Its composition, rich in manganese and silicon, enhances deoxidization, ensuring smooth bead formation and minimal cleanup.

Ideal for industries such as automotive, shipbuilding, and machine engineering, the rod supports high welding currents with 100% CO2 shielding gas.

Ultimately, the ER70S-6’s adaptability and reliability make it a valuable asset for diverse welding projects.

Customer Feedback and Support

While evaluating the Mild Steel TIG Welding Rod ER70S-6, customer feedback reveals a generally positive reception, underscoring its reliability and performance across various welding applications.

With a commendable customer satisfaction rating of 4.7 out of 5 stars, users appreciate the rod’s smooth weld beads and minimal cleanup.

Warranty details further enhance its appeal, offering a 30-day free return and exchange alongside a 2-year warranty, ensuring buyers feel secure in their investment.

This level of support, combined with favorable reviews, contributes to the rod’s reputation as a trusted choice among welders seeking quality and durability in their projects.

Frequently Asked Questions

What Is the Recommended Storage Method for the Welding Rod?

The recommended storage method for the welding rod involves humidity control and temperature regulation. Maintaining a dry, cool environment prevents moisture absorption, ensuring peak performance and longevity, liberating users from concerns about rod degradation.

Is This Rod Suitable for Outdoor Welding Conditions?

The rod demonstrates commendable outdoor performance, handling various weather conditions effectively. Its design supports consistent weld quality, making it suitable for outdoor projects where environmental factors may influence welding outcomes, empowering users to tackle diverse challenges confidently.

Can This Rod Be Used With Other Shielding Gases?

This rod dazzles with versatility, embracing various shielding gas options beyond CO2. Its welding gas compatibility allows for experimentation, liberating welders to explore diverse techniques and achieve stunning results in their creative endeavors.

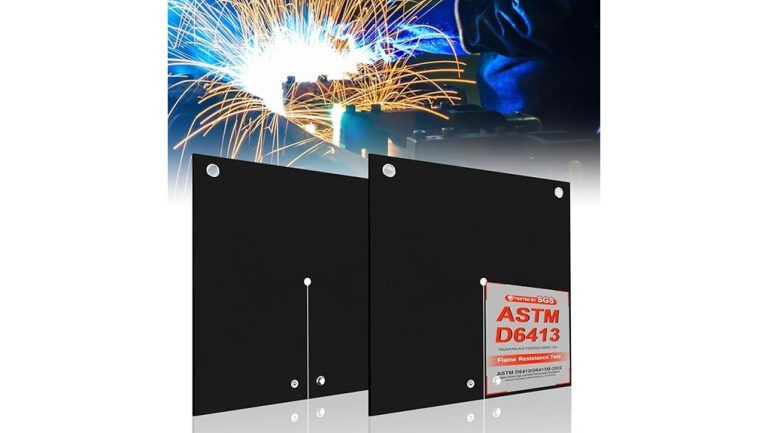

What Safety Gear Is Recommended When Using This Welding Rod?

Welding safety mandates the use of protective equipment such as helmets, gloves, and flame-resistant clothing. This gear guarantees protection against sparks, heat, and harmful radiation, allowing welders the freedom to work confidently and securely.

How Should the Welding Rod Be Cleaned Before Use?

How can one guarantee peak performance during welding? Proper welding rod preparation involves cleaning techniques such as removing oils, dirt, and oxidation, confirming the rod is pristine for a flawless, liberated welding experience.

Conclusion

In the domain of welding, the Mild Steel TIG Welding Rod ER70S-6 stands as a steadfast companion, much like a reliable ship maneuvering through turbulent waters. With its low alloy steel composition and high manganese and silicon content, it guarantees smooth welds and minimal cleanup. Whether you are forging automotive components or constructing vessels, this rod offers durability and performance. For both beginners and seasoned welders, it illuminates the path to successful projects, proving to be a wise investment.