The 3mirrors Silicone Purge Plugs Kit offers a thorough solution for welding professionals, featuring 14 plugs designed for pipe diameters ranging from 0.9 to 4.0 inches. Made from high-temperature silicone resin, these plugs withstand conditions up to 600°F while minimizing oxidation during the welding process. Their reusable nature not only enhances cost-effectiveness but also supports sustainable practices. This kit is poised to improve weld quality considerably, prompting further exploration of its installation and user experience.

Key Takeaways

- The 3mirrors Silicone Purge Plugs Kit includes 14 versatile plugs for pipe diameters ranging from 0.9 to 4.0 inches.

- Made from high-temperature silicone resin, these plugs withstand temperatures up to 600°F and resist rupture.

- Users appreciate the easy installation process and the importance of selecting the correct size for optimal sealing.

- The reusable design is cost-effective and sustainable, while the stainless steel filter screen optimizes inert gas usage.

- Overall, the kit enhances welding quality by minimizing oxidation and has received positive feedback for its durability and adaptability.

Overview of the 3mirrors Silicone Purge Plugs Kit

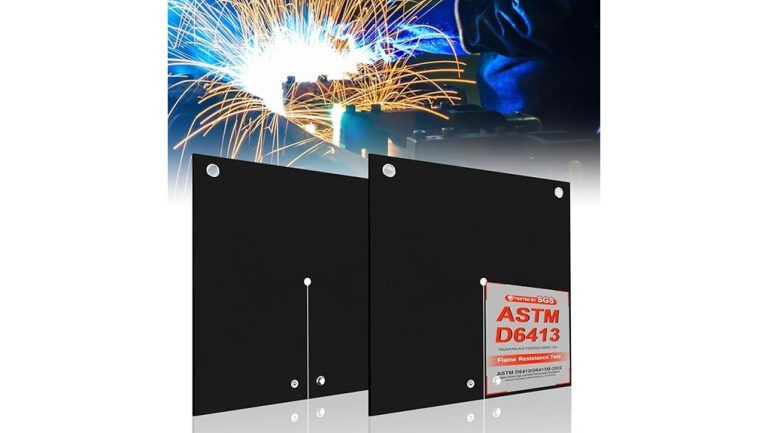

The 3mirrors Silicone Purge Plugs Kit stands out as a versatile solution for welding professionals, featuring an extensive range of 14 plugs across seven size sets, specifically designed to accommodate pipe diameters from 0.9 inches to 4.0 inches.

Its design features include a flexible, high-temperature silicone resin that withstands up to 600°F, ensuring durability and resistance to rupture. This material benefits users by offering reusability and adaptability to various pipe surfaces.

Additionally, each plug is equipped with a stainless steel filter screen that optimizes inert gas usage, enhancing welding quality and minimizing oxidation risks while maintaining a strong sealing effect.

Benefits of Using Silicone Purge Plugs

Using silicone purge plugs offers numerous advantages for welding applications, particularly when it comes to ensuring high-quality welds and minimizing oxidation. The materials used provide a durability comparison that outperforms traditional options, making them a reliable choice for welders.

| Feature | Benefit |

|---|---|

| High-Temperature Resistance | Withstands up to 600°F |

| Flexible Design | Adapts to multiple pipe sizes |

| Reusable | Cost-effective and sustainable |

Installation tips include ensuring a snug fit, which prevents gas leakage and optimizes performance. Overall, these plugs enhance welding efficiency while protecting against corrosion, ensuring superior results.

Installation and User Experience

When it comes to the installation of the 3mirrors Silicone Purge Plugs, users will find that the process is designed to be both straightforward and efficient.

Following some installation tips can enhance the experience:

- Confirm the correct size plug is selected for ideal sealing.

- Utilize the installation sleeve for smooth changes between plugs.

- Secure hoses tightly to prevent leakage during operation.

User feedback highlights the plugs’ adaptability to threaded and non-threaded holes, making them versatile.

The plugs’ versatility shines through their ability to fit both threaded and non-threaded holes seamlessly.

The intuitive design facilitates quick installation, while the durable silicone material guarantees long-lasting use, reinforcing confidence in their performance during welding applications.

Frequently Asked Questions

Are These Plugs Compatible With All Pipe Materials?

The plugs offer versatile pipe compatibility, accommodating various materials effectively. Their material durability guarantees resilience under high temperatures, promoting ideal performance and freedom from oxidation, making them suitable for diverse welding applications and enhancing overall efficiency.

How Do I Clean the Silicone Purge Plugs After Use?

Cleaning methods for silicone purge plugs involve gentle scrubbing with warm soapy water, ensuring every crevice gleams. Maintenance tips suggest routine inspections, revealing their full potential, and liberating welders from the shackles of oxidation and residue.

Can These Plugs Be Used for High-Pressure Applications?

These plugs exhibit reliable high pressure performance due to their silicone durability, effectively sealing under intense conditions. Users can confidently employ them, knowing they maintain integrity and support liberation from concerns regarding pressure-related failures.

What Is the Warranty Period for the Product?

The warranty details for the product typically guarantee a satisfactory product lifespan, reflecting the manufacturer’s confidence in their design. Such assurance empowers users to trust in the durability and reliability of their investment.

Are Replacement Plugs Available for Purchase Separately?

Replacement options for the plugs are available for separate purchase. Interested users can find purchasing details through various online retailers, ensuring they can maintain their equipment’s functionality and prolong its effective use in diverse applications.

Conclusion

In conclusion, the 3mirrors Silicone Purge Plugs Kit stands out as a practical tool for welding professionals, offering a range of 14 plugs suitable for pipe diameters from 0.9 to 4.0 inches. Crafted from high-temperature silicone resin, they provide durability and flexibility, ensuring high-quality welds by minimizing oxidation. With a reusable design that promotes sustainability, this kit not only enhances performance but also proves to be a cost-effective solution, making it an indispensable addition to any welding toolbox.