The 50Pcs Flux Core Aluminum Welding Rods feature a low melting point of 550℃, making them suitable for delicate repairs without warping. Each rod is designed for high strength and excellent forgeability, ideal for various applications, from small repairs to custom projects. Users benefit from a 90-day return policy and responsive customer support, enhancing overall satisfaction. With such versatile specifications, many wonder how these rods compare to traditional welding methods in different scenarios.

Key Takeaways

- The 50Pcs Flux Core Aluminum Welding Rods are made from premium aluminum, ensuring durability and resistance to corrosion for various projects.

- With a melting point of 550℃ (1022℉), these rods are ideal for delicate welding without warping materials.

- Users appreciate the ease of use, as there’s no need for additional solder powder during the welding process.

- Customer feedback highlights the product’s high strength and good forgeability, making it suitable for aluminum repairs and creative projects.

- The brand offers a 90-day return or replacement policy, underscoring their commitment to customer satisfaction and support.

Product Features and Specifications

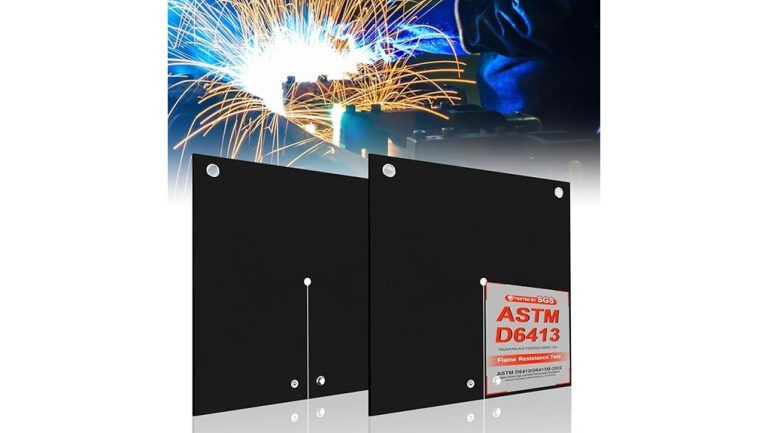

When evaluating the 50Pcs Flux Core Aluminum Welding Rods, one finds a product designed specifically for small aluminum projects that require effective welding solutions.

Crafted from premium, nontoxic aluminum, these rods exhibit remarkable product durability and exceptional welding efficiency. With a melting point of 550℃ (1022℉), they guarantee reliable performance even at lower temperatures.

Significantly, there is no need for additional solder powder, simplifying the welding process. Their high strength, good forgeability, and resistance to corrosion make them ideal for various applications.

Application Areas and Benefits

The 50Pcs Flux Core Aluminum Welding Rods are versatile tools designed for a range of applications, particularly in small-scale aluminum projects.

These rods excel in various welding techniques, making them ideal for tasks such as repairing aluminum frames, crafting custom metal art, and connecting components in electrolytic aluminum plants.

Their low melting point of 550℃ (1022℉) allows for efficient use on delicate materials without warping.

Project examples include joining aluminum alloy pieces in electric power installations or chemistry applications.

Their high strength and corrosion resistance guarantee durable results, enabling creators to pursue innovative designs with confidence and ease.

Customer Experience and Support

Customer experience with the 50Pcs Flux Core Aluminum Welding Rods reflects a strong emphasis on satisfaction and reliability.

Customers frequently praise the product’s effectiveness in various applications, often highlighting its high strength and good forgeability.

Customer feedback indicates that inquiries are met with commendable support responsiveness, ensuring users feel valued.

The 90-day return or replacement policy further reinforces a commitment to customer assurance.

This approach cultivates trust, allowing users to engage in small aluminum projects with confidence.

Through attentive support and quality products, the overall experience fosters a sense of liberation in achieving successful welding outcomes without unnecessary hurdles.

Frequently Asked Questions

Can These Rods Be Used for Repair Work on Vehicles?

These rods can be employed for repair techniques on vehicles, offering good vehicle compatibility. Their strength and corrosion resistance make them suitable for small aluminum repairs, enhancing the liberation of creative automotive solutions.

What Tools Are Required for Using These Welding Rods?

Using flux core aluminum welding rods requires essential welding equipment, including a suitable welding machine, protective gear, and tools for surface preparation. Proper setup empowers individuals to undertake projects, fostering creativity and independence in their endeavors.

Are There Any Safety Precautions to Follow While Welding?

Welding safety necessitates the use of protective gear, including gloves, helmets, and aprons, to safeguard against sparks, heat, and harmful fumes. Proper ventilation and awareness of surroundings further enhance safety during the welding process.

How Long Do the Rods Last Once Opened?

Once opened, rod lifespan depends on storage conditions and usage frequency. Properly stored rods maintain peak performance for several months, ensuring reliable results in various projects, enhancing the user’s freedom in creative aluminum applications.

Is There a Recommended Storage Method for These Rods?

“An ounce of prevention is worth a pound of cure.” For best performance, store the rods in a cool, dry place, ensuring temperature control to prevent moisture damage and maintain ideal conditions for longevity.

Conclusion

In conclusion, the 50Pcs Flux Core Aluminum Welding Rods stand out as a practical tool for various aluminum projects. With a low melting point of 550℃, they provide excellent control for delicate work, ensuring materials remain unwarped. Their strength and forgeability make them suitable for repairs and custom tasks alike. Backed by a responsive support team and a 90-day return policy, these rods represent a sturdy ally for both hobbyists and professionals steering through the world of aluminum welding.