Ceramic fiber insulation is designed for high-temperature applications, with a remarkable temperature rating of up to 2400°F. Weighing only 8 lb/ft³, it is lightweight and easy to install, making it suitable for various uses, including fireplaces and industrial processes like welding. Its thermal efficiency not only reduces energy costs but also extends the lifespan of equipment. This versatile insulation material warrants a closer examination of its key features, applications, and benefits for industrial settings.

Key Takeaways

- Ceramic fiber insulation performs exceptionally well in high-temperature environments, rated for temperatures up to 2400°F.

- Its lightweight nature facilitates easy handling and installation, making it ideal for various applications.

- The insulation offers significant energy savings and enhances equipment lifespan through superior thermal efficiency.

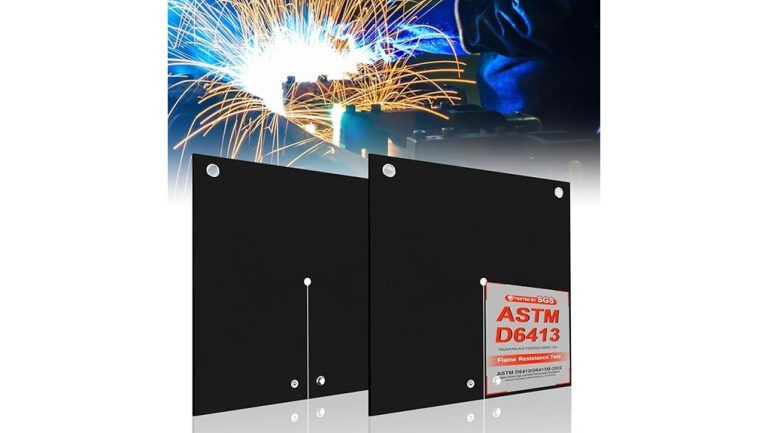

- Fireproof capabilities make it suitable for use in fireplaces, wood stoves, and industrial applications like welding.

- Proper installation and sealing are crucial to maximizing its insulation effectiveness and ensuring reliable performance.

Key Features of Ceramic Fiber Insulation

Ceramic fiber insulation, renowned for its exceptional performance in high-temperature environments, boasts several key features that make it an essential choice for both residential and industrial applications.

Rated for temperatures up to 2400°F, it meets rigorous safety standards, ensuring reliable performance. With a density of 8 lb/ft³ and dimensions of 2″ thick by 16″ by 48″, it is versatile for various uses.

Installation guidelines recommend careful handling due to its lightweight nature. The insulation’s fireproof capabilities further enhance its appeal, making it suitable for fireplaces, furnaces, and kilns.

These features combine to offer unmatched protection and efficiency in demanding scenarios.

Applications in High-Temperature Environments

High-temperature environments demand reliable insulation solutions, and ceramic fiber insulation excels in this regard due to its versatile applications.

Significantly, it serves effectively in fireplace applications and wood stove installations, where it withstands extreme heat. This insulation boasts a temperature rating of 2400°F, ensuring safety and performance.

Its lightweight structure facilitates easy handling and installation, making it an ideal choice for setups like wood stove baffles and chimney linings. Additionally, ceramic fiber insulation is fireproof, providing peace of mind in high-heat scenarios.

Its adaptability extends to various other uses, ensuring extensive coverage for diverse heating needs in residential and commercial settings.

Benefits for Industrial Uses

In industrial settings, the advantages of ceramic fiber insulation are numerous and impactful, particularly in applications that require superior thermal performance.

Its attributes promote enhanced operational efficiency and reduced costs.

Key benefits include:

Key benefits encompass exceptional thermal efficiency, significant cost savings, and versatile applications in high-temperature environments.

- Exceptional thermal efficiency, maintaining stability in extreme temperatures.

- Significant cost savings through reduced energy consumption and extended equipment lifespan.

- Versatility across multiple high-temperature applications, such as welding and glass blowing.

- Lightweight composition that simplifies installation and handling.

Frequently Asked Questions

How Is Ceramic Fiber Insulation Installed?

Ceramic fiber insulation installation techniques involve measuring, cutting to size, and securing sheets in desired insulation applications, ensuring tight fits and proper sealing to maximize efficiency. Proper handling and safety precautions are essential during installation.

Is Ceramic Fiber Insulation Safe for Home Use?

Ceramic fiber insulation is generally safe for home use when adhering to safety regulations. However, potential health risks may arise from dust exposure, necessitating proper installation and protective measures to guarantee a liberated, healthy living environment.

Can Ceramic Fiber Insulation Be Cut to Size?

Ceramic fiber insulation can indeed be cut to size, allowing for effective size customization. Various cutting techniques, such as using a utility knife or specialized tools, guarantee precise measurements for specific applications, enhancing versatility and adaptability.

What Is the Lifespan of Ceramic Fiber Insulation?

The lifespan of ceramic fiber insulation largely depends on durability factors and temperature stability. Under ideal conditions, it can last several years, maintaining its integrity in high-temperature applications, providing reliable performance across various industrial uses.

Are There Any Environmental Concerns With Ceramic Fiber Insulation?

Environmental concerns arise from ceramic fiber insulation’s health risks, particularly when fibers become airborne. While effective in high-temperature applications, users must weigh performance against potential long-term impacts on both personal health and ecological systems.

Conclusion

In conclusion, ceramic fiber insulation emerges as a cornerstone for high-temperature applications, withstanding extremes up to 2400°F while maintaining a lightweight profile of just 8 lb/ft³. Its unique properties not only enhance thermal efficiency but also extend the lifespan of equipment, painting a picture of reliability in demanding environments. Whether used in fireplaces or industrial settings like welding, this insulation offers a blend of performance and practicality, making it an indispensable choice for those seeking effective thermal management solutions.