The 2PCS Soldering Lugs serve as a practical solution for electronic repairs, offering enhanced functionality and efficiency. Designed to replace conventional jump wire methods, these lugs effectively restore missing solder joints and original pads without leaving unwanted traces. Constructed from industrial-grade copper foil, they guarantee strong connections and durability, making them suitable for intricate devices such as phones and PCBs. Understanding their design features and overall reliability can greatly impact repair outcomes.

Key Takeaways

- The 2PCS Soldering Lugs streamline the repair process, replacing traditional jump wires and filling missing solder joints effectively.

- Crafted with industrial-grade copper foil, these lugs ensure strong connections and durable performance in electronic repairs.

- Their reinforced pads with fixed pins provide stability, enhancing the reliability and effectiveness of repairs on intricate devices.

- The lugs restore original pads without leaving traces, promoting a clean and professional finish in electronic projects.

- Designed for ease of use, these lugs save technicians time and effort, improving overall efficiency in repair tasks.

Functionality and Efficiency of Soldering Lugs

The functionality and efficiency of 2PCS soldering lugs are notable, particularly in their capacity to streamline the repair process for various electronic components.

These lugs replace the traditional jump wire method, effectively filling missing solder joints and restoring the original pad without leaving a trace.

By enhancing the repair process, they save both time and effort, eliminating the need for tedious circling during jump wire application.

Enhancing the repair process, these lugs save time and effort by eliminating tedious jump wire applications.

With their robust design, these lugs guarantee a firm connection, thereby improving the overall effectiveness of repairs on intricate devices such as phones and PCBs, ultimately liberating technicians from cumbersome soldering challenges.

Design Features and Materials

Design features of the 2PCS soldering lugs highlight their advanced construction, which is tailored for perfect performance in electronic repairs.

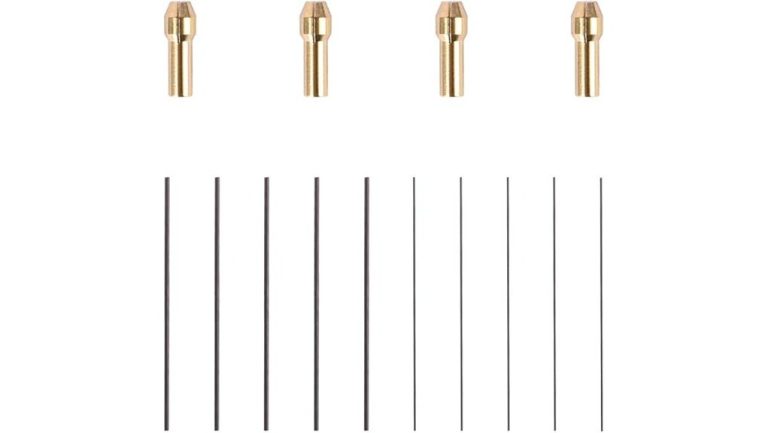

The design innovation is evident in the reinforced pads with fixed pins, guaranteeing stability and preventing detachment during use. Crafted with industrial-grade printed circuit board copper foil, these lugs feature a thickness of 30μm, which enhances material quality and guarantees peak conductivity.

Their superior flatness minimizes the risk of pseudo soldering, providing a reliable surface for effective connections. This thoughtful design not only facilitates ease of use but also enhances the overall efficiency of electronic repair tasks, promoting successful outcomes.

Durability and Reliability in Electronic Repairs

Durability and reliability are essential factors in the performance of the 2PCS soldering lugs, especially when employed in electronic repairs.

Designed for long-lasting performance, these lugs showcase strong welding strength, ensuring resistance to drops and unsoldering. Their industrial-grade printed circuit board copper foil, at a thickness of 30μm, supports the integrity of connections.

This contributes to repair convenience, as users can efficiently restore original pads without traces, enhancing the overall repair process. With a firm connection joint, these lugs effectively address issues with green oil, providing stable electrical performance that users can trust for reliable results in various applications.

Frequently Asked Questions

How Do I Properly Use Soldering Lugs in Repairs?

To properly use soldering lugs in repairs, one should master soldering techniques, ensuring accurate lug installation on PCB pads. This enhances electrical connections while providing a reliable, durable solution for electronic restoration and maintenance tasks.

Are Soldering Lugs Compatible With All Types of PCBS?

Soldering lugs exhibit broad compatibility across various PCB types, enhancing repair possibilities. Their design enables effective connections, making them suitable for diverse applications while ensuring reliability and performance in electronic repairs without compromising quality.

Can Soldering Lugs Be Reused After Initial Application?

Soldering lugs generally exhibit durability, but reuse considerations depend on prior application stress. While some may withstand reattachment, repeated use can compromise effectiveness, potentially leading to unreliable connections and diminished performance in electronic repairs.

What Soldering Equipment Works Best With These Lugs?

Ideal soldering techniques include using high-quality soldering irons and precise temperature control, while lug materials should be compatible with PCB specifications. Effective equipment enhances bond strength and guarantees reliable electronic repairs, promoting efficiency and longevity.

Where Can I Purchase Replacement Soldering Lugs if Needed?

Potential buyers could explore various replacement sources online, such as electronics retailers and specialized repair shops. Multiple purchasing options exist, ensuring that enthusiasts can swiftly reclaim their repair freedom with reliable soldering lugs at their fingertips.

Conclusion

To summarize, the 2PCS Soldering Lugs stand out as an essential tool for electronic repairs, bridging the gap left by missing solder joints. With their industrial-grade copper foil construction, they promise both durability and reliable connections, making them suitable for delicate devices. By simplifying the repair process, these lugs allow technicians to work efficiently, ensuring a seamless restoration of functionality. Ultimately, investing in quality tools like these soldering lugs can help one avoid the pitfalls of subpar repairs.