Like a chain only as strong as its links, your Powermax 105 depends on the right consumables installed in the right order. You’ll confirm kit compatibility (228849 starter, 851471 handheld), inspect for dings, then stack electrode, nozzle, retaining cap, and deflector. Keep your air bone-dry to avoid double-arcing and sputter. Dry-fire to validate gas flow and ignition. Next, you’ll match handheld vs. mechanized parts, set pierce expectations, and time replacements—precisely.

Kit Overview and Compatibility

Built for 105 A handheld cutting, the Powermax105 consumables kit delivers high-duty performance and long life across the Powermax series. You’ll use it for production-grade handheld work where arc stability, cut quality, and duty cycle matter.

The kit features CopperPlus electrodes engineered to extend wear life when you’re cutting 12 mm (1/2 inch) and under, reducing tip-in changes and minimizing downtime. A deflector supports unshielded cutting when access is tight, while the ohmic retaining cap guarantees reliable height sensing and consistent arc starts.

You gain system versatility because the kit is compatible across the entire Powermax lineup, so you can standardize consumables whether you’re running a 65, 85, 105, or 125 platform.

Match the kit to handheld torches for clean kerfs, controlled dross, and predictable consumable burn profiles. Source through authorized distributors to guarantee genuine parts and localized pricing.

Use this kit when you need predictable performance, simplified stocking, and repeatable handheld cut results.

Essential Part Numbers and Components

You’ll reference core kit components like CopperPlus electrodes, Ohmic retaining caps, and the correct amperage nozzles to match your cut specs.

Call out key part numbers—228849 (starter kit), 851471 (handheld kit), 851472 (mechanized kit), plus nozzles 220819 (65 A drag) and 220816 (85 A)—so you can order accurately.

Note compatibility by torch type and amperage to prevent misfires, premature wear, and suboptimal cut quality.

Core Kit Components

Two essentials define the Powermax105 Consumable Starter Kit (Hypertherm 228849): CopperPlus electrodes and matched nozzle options complemented by an ohmic retaining cap.

You’ll deploy this trio to stabilize the arc, manage heat load, and maintain cut quality at 105 A across varied materials. For cutting techniques, pair CopperPlus with the appropriate nozzle orifice to balance kerf width, dross control, and travel speed, especially on ≤12 mm stock where electrode life extends considerably.

The ohmic retaining cap enables reliable surface sensing, improving pierce height accuracy and consumable longevity.

Apply disciplined maintenance practices: inspect nozzle wear (orifice ovality, nicks), track electrode pit depth, and clean the cap’s contact surfaces to preserve sensing continuity.

Keep components dry, handle with lint-free gloves, and torque assemblies per torch spec for repeatable performance.

Key Part Numbers

Part numbers anchor your ordering and maintenance workflow for the Powermax105. Treat them as traceable identifiers that lock in performance, price, and availability.

The Hypertherm 228849 Consumable Starter Kit ($147.55) is your baseline: it bundles CopperPlus electrodes optimized for 12 mm (1/2 inch) and under, plus the Ohmic retaining cap—both critical for consistent arc starts and consumable longevity.

For mechanized use, the Hypertherm 851472 Essential Mechanized Consumable Kit ($268.32) streamlines procurement and setup. Leverage part number significance to prevent mis-picks and guarantee you’re loading OEM-matched interfaces.

- Verify 228849 for handheld starter coverage (CopperPlus electrodes, Ohmic cap).

- Flag 851472 for mechanized consumable assortments.

- Cross-check packaging labels against PO and job spec.

- Use kit identification tips: compare SKU, contents list, and price point to confirm authenticity.

Compatibility Notes

With the key SKUs identified, align components to the Powermax105’s approved stack-up to avoid mismatch errors and premature wear.

Prioritize consumable selection that’s validated for the Powermax series—mixing non-series parts undermines arc stability, cut quality, and duty cycle. The Hypertherm 228849 Consumable Starter Kit is purpose-built for this model; use it as your baseline for compatibility importance.

Match the CopperPlus electrode when cutting 12 mm (1/2 inch) and under to extend life and maintain consistent arc transfer.

Pair the ohmic retaining cap only with torches configured for ohmic sensing to preserve pierce height accuracy. Use the deflector for unshielded cutting only in processes that specify it; otherwise, opt for the correct shield.

Validate air quality—dry, clean air is critical; moisture accelerates nozzle/electrode erosion and shortens service intervals.

Handheld vs. Mechanized Options

Although both approaches run the same plasma power, handheld and mechanized setups demand different consumables to hit spec. You’ll see clear handheld benefits in maneuverability and on-the-fly edge access, while mechanized efficiency shines in repeatability and cut quality.

The Powermax105 kits are purpose-built: the Essential Handheld kit runs $237.03 and includes items like the CopperPlus electrode and deflector optimized for manual control; the Essential Mechanized kit runs $268.32, tuned for CNC torch height control and tighter kerf.

Choose nozzles by process. For hand cutting, a drag cutting nozzle like Hypertherm 220819 (65 A) tolerates tip contact and variable travel speed. For automated tables, a 105 A nozzle maintains column integrity at programmed speeds.

- Match amperage to material thickness and expected duty cycle.

- Budget consumable wear; handheld sets typically turn over faster.

- Verify torch type and cap/retaining compatibility.

- Standardize part numbers to simplify inventory and job setups.

Air Filtration and Drying Best Practices

Nothing protects Powermax105 consumables like dry, clean air delivered at spec. You’ll extend electrode and nozzle life dramatically when you prioritize moisture control and air quality.

Moisture nukes arc stability, spikes dross, and slashes pierce counts. Users running proper drying routinely report ~800 pierces on electrodes and ~400 on nozzles.

Build a staged air train: water separator first to knock out bulk liquid, then a coalescing filter to strip aerosols, followed by a desiccant dryer to pull remaining vapor, and finish with a Motorguard for fine particulate polishing.

Plumb it close to the cutter to minimize recondensation and keep pressure drop low with full‑flow fittings and adequately sized hose.

Even in dry climates like Central California, ambient swings can condense water in lines.

Purge bowls, replace desiccant when color changes, and monitor differential pressure across filters.

Share your results and settings—community feedback tightens best practices and cuts consumable spend.

Installation and Setup Checklist

Preparation sets the tone for consumable life and cut quality. Before you power up, verify you’ve got the Hypertherm 228849 Consumable Starter Kit for Powermax105 and confirm it matches your torch (handheld configuration).

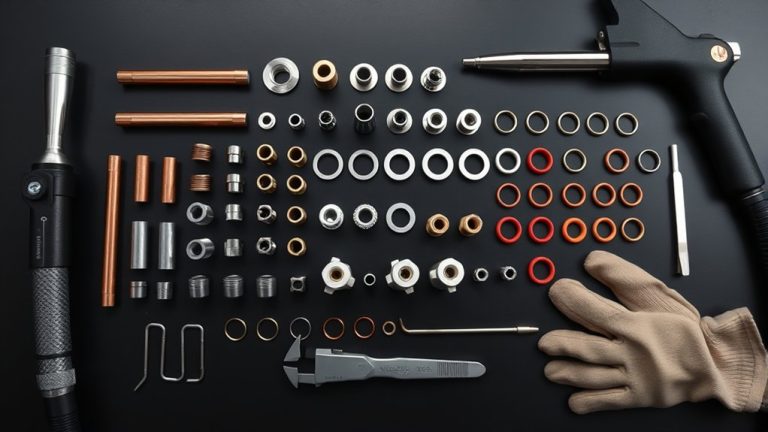

Lay out components, inspect threads and O-rings, and clean mating surfaces to prevent leaks and arc instability.

Follow installation procedures in sequence: seat the CopperPlus electrode, install the nozzle, align the ohmic retaining cap, then fit the deflector. Hand-tighten, then snug to spec—don’t over-torque.

Verify air drying hardware (coalescing and desiccant filters) is purged and charged to keep moisture out of the gas stream.

- Confirm correct part numbers and amperage rating for the job

- Check swirl ring orientation and electrode depth stop

- Validate torch lead connections and strain relief

- Perform an ohmic continuity test at the cap

Run a brief dry-fire test to confirm arc start and gas flow.

For setup troubleshooting, watch for double-arcing, sputter, or a wandering kerf—recheck cap seating, air dryness, and nozzle/electrode wear.

Regularly inspect and replace worn tips to maintain cut consistency.

Expected Pierce Counts and Replacement Timing

Even with ideal parameters and dry air, you should baseline pierce counts at roughly 400 per nozzle and 800 per electrode on a Powermax105, then adjust based on your process data.

Expect pierce count variability; moisture impact is the primary driver. If your air system carries condensate, nozzle life can drop to ~200 pierces. Verify your dryer, filters, and separators are sized for flow and maintained.

Track pierces per part program and reconcile against consumable lot, gas quality, and duty cycle. Replace nozzles when kerf widens, arc wanders, or dross increases at unchanged cut specs.

Replace electrodes when the hafnium pit approaches 1 mm depth or arc starts hard. Don’t run to failure; swap at trend thresholds to protect the swirl ring and shield.

If you’re using ATTC parts, plan for up to ~500 pierces per nozzle and ~1,000 per electrode, but validate with your logs.

Document changeouts, compare weekly averages, and tighten intervals when variation spikes.

Performance Tips for Cut Quality and Durability

While dialing in a Powermax105 for consistent cut quality, prioritize a tight air system, correct stack-up, and disciplined consumable care.

Run a robust air drying train—refrigerated dryer, coalescing filter, and point-of-use desiccant—to keep moisture out; wet air slashes pierce counts and destabilizes the arc.

Use the CopperPlus electrode for steel up to 12 mm; it’s proven to extend life and stabilize cut faces. Match nozzle and retaining cap part numbers; a mismatched stack shifts kerf bias, skews cut direction, and erodes edge fidelity.

Build maintenance routines that include torch inspection, bore cleaning, and timely swaps of worn parts to sustain cut quality.

- Verify torch stack-up torque and O-ring condition before shifts

- Log pierces per electrode; retire around trend breakpoints approaching 800

- Tune cutting techniques: correct standoff, amperage, gas flow, and speed for material

- Inspect nozzles for orifice ovality; replace at first sign of bevel drift

Clean, dry air plus correct components yields durable consumables and repeatable cuts.

Where to Buy and Regional Availability

Looking to source a Powermax105 consumables kit? Start with Hypertherm’s authorized network. Use their partner locator, submit your region, and shortlist regional distributors that stock your torch model and amperage range.

Product availability is location-dependent, so verify specific part numbers and nozzle/electrode variants before you place a PO. If you’ve pre-selected items, bring the list to an authorized distributor or contact Hypertherm directly for guidance and substitutions.

Availability varies by location—confirm part numbers and variants before your PO, and consult authorized distributors for guidance.

For pricing, rely on authorized channels—distributors provide current list and net costs, lead times, and any MOQs. In established markets like the UK and UAE, product availability is generally strong, but stock positions vary by country; confirm on-hand quantities and replenishment ETAs.

Request documentation: authenticity, lot codes, and compatibility with your Powermax105 torch. Ask about bundled kits, freight options, and regional warranty terms.

Pro tip: lock in a reorder cadence. Share your average burn rate so the distributor can buffer inventory and reduce downtime.

Frequently Asked Questions

How Do I Store Spare Consumables to Prevent Corrosion or Damage?

Store consumables in sealed, labeled containers with desiccant packs for consumable storage and corrosion prevention. Maintain 40–60% RH, 15–25°C. Avoid fingerprints; handle with nitrile gloves. Keep away from ozone, solvents, UV. Rotate stock FIFO. Inspect O-rings; rebag immediately.

What Signs Indicate Counterfeit Consumables Versus Genuine Parts?

You spot counterfeit indicators by inconsistent machining, off-spec plating, poor engraving, mismatched or missing lot codes, and subpar packaging. For genuine verification, cross-check holograms, serials, and barcodes with the manufacturer; validate weight, tolerances, and arc performance against spec.

Can I Track Pierce Counts Digitally With Compatible Cutters?

Yes—you can. Think airplane flight logs: you’ll use digital tracking and pierce monitoring via CNC controller diagnostics, arc-on timers, and torch-lift counters. Configure post-process reports, export CSVs, and set tool-life thresholds to automate alerts and maintenance intervals.

Are There Environmental Disposal Guidelines for Used Electrodes?

Yes. You should follow environmental regulations: segregate copper/tungsten, label hazardous residues, and use used electrode recycling streams. Don’t landfill. Verify RCRA/REACH/WEEE applicability, obtain manifests, document chain-of-custody, and coordinate with certified metal reclaimers or universal waste handlers.

How Does Ambient Temperature Affect Consumable Lifespan?

Ambient temperature directly impacts consumable lifespan: you’ll see accelerated wear in high heat due to arc instability and increased oxidation; cold temps risk condensation and microcracking. Maintain 60–80°F, control humidity, precondition cartridges, and stabilize duty cycle to optimize longevity.

Conclusion

You’ve got the Powermax 105 consumables kit dialed: confirm 228849 and 851471, inspect for “cosmetic surprises,” and stack in sequence—electrode, nozzle, retaining cap, deflector. Keep your air bone-dry with solid filtration, then dry-fire to avoid “unplanned fireworks.” Track pierce counts to retire parts before they’re “past their prime.” Whether handheld or mechanized, stick to the checklist, and you’ll hold kerf, minimize dross, and extend duty cycles—without any mid-shift “unscheduled pauses.”