The welding ground clamp is an essential component for any welder, designed primarily for superior conductivity with its high-grade copper construction. Measuring approximately 6 inches in length, it features a robust spring mechanism that securely grips workpieces, thereby reducing electrical faults. The electroplated finish not only enhances durability but also resists wear and tear. Regular maintenance can further optimize performance, making this clamp an indispensable tool for achieving consistent grounding. What other features make this clamp stand out?

Key Takeaways

- High-grade copper construction ensures superior conductivity and reliable electrical connections during welding tasks.

- Strong spring mechanism provides exceptional clamping power for secure attachment to workpieces.

- Electroplated finish enhances durability, protecting the clamp from wear and corrosion over time.

- Regular maintenance and inspection are essential for optimal performance and safety in welding operations.

- Capable of handling up to 500A, ensuring compatibility with various welding equipment and applications.

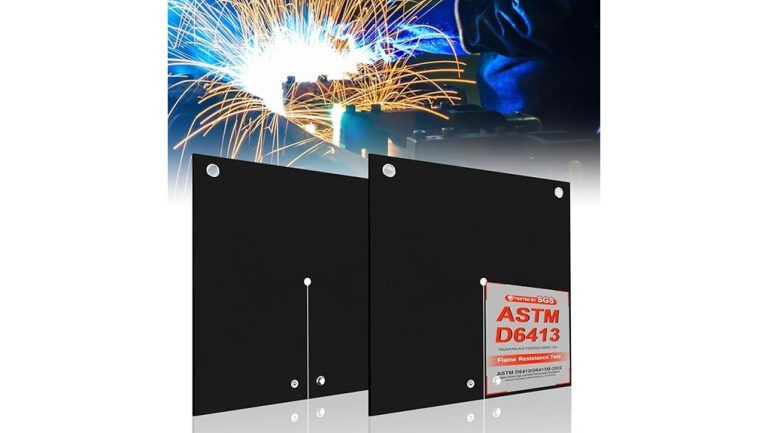

Material and Construction Quality

When considering the welding ground clamp, the quality of material and construction plays a pivotal role in its overall effectiveness.

Crafted from high-grade copper, this clamp guarantees superior copper conductivity, crucial for optimum electrical performance. The electroplated finish enhances its durability, providing resistance against wear and tear over time.

Crafted from premium copper, this clamp ensures exceptional conductivity and durability, elevating your welding performance.

This robust construction not only supports reliable connections during welding but also extends the lifespan of the clamp, allowing users to work with confidence. Such attention to material quality transforms the welding experience, granting freedom from concerns about grounding issues.

Ultimately, a well-constructed clamp is essential for any serious welder.

Performance Features and Benefits

The welding ground clamp stands out due to its impressive performance features, designed to enhance both efficiency and safety during welding tasks.

With a strong spring mechanism, it delivers exceptional clamping power, ensuring secure attachment to workpieces. This reliable clamp guarantees superior electrical connections, essential for effective grounding, thereby reducing the risk of electrical faults.

The quality copper construction facilitates excellent conductivity, while its electroplated finish enhances durability.

Safety and Compatibility Considerations

Safety remains a paramount concern in any welding operation, especially when considering the use of a welding ground clamp.

Safety is crucial in welding operations, particularly when utilizing a welding ground clamp.

Confirming safe usage and compatibility involves adhering to specific guidelines and maintenance practices.

- Usage Guidelines: Always connect the clamp to a clean, unpainted surface to maximize conductivity.

- Maintenance Tips: Regularly inspect the clamp for wear and corrosion to confirm reliable performance.

- Compatibility: Verify that the clamp’s specifications match the welder’s requirements, confirming it can handle the intended amperage of up to 500A.

Following these considerations will enhance safety and operational efficiency during welding tasks.

Frequently Asked Questions

How Do I Properly Maintain My Welding Ground Clamp?

To maintain a welding ground clamp, employ regular cleaning techniques to remove debris, and utilize inspection methods to check for wear or damage. This guarantees peak performance and longevity, enhancing safety and efficiency during welding tasks.

What Is the Warranty Period for This Welding Ground Clamp?

The welding ground clamp offers a one-year warranty period, symbolizing a guardian’s embrace. Warranty coverage guarantees protection against defects, allowing users to work freely, knowing their tool’s reliability is backed by the manufacturer’s commitment.

Can This Clamp Be Used for Outdoor Welding Applications?

This clamp demonstrates outdoor durability due to its robust construction and weather resistance, making it suitable for outdoor welding applications. Its design guarantees reliable performance against various environmental conditions, empowering welders to work confidently in diverse settings.

What Is the Weight of the Welding Ground Clamp?

The welding ground clamp weighs approximately 1.5 pounds, a lightweight choice that enhances portability. Its durable construction guarantees reliability, allowing users to liberate their welding potential without the burden of cumbersome equipment during weight comparisons.

Are There Any Specific Brands Recommended for Compatibility?

Miller Electric and Lincoln Electric are highly recommended brands for welding ground clamps. Their products guarantee compatibility and reliability, empowering users to achieve peak performance in their welding tasks while promoting safety and efficiency during operation.

Conclusion

To sum up, the welding ground clamp is an essential tool for welders, boasting high-grade copper construction, a robust spring mechanism, and an electroplated finish for enhanced durability. Significantly, studies show that proper grounding can reduce electrical faults by up to 80%, emphasizing the clamp’s importance in ensuring safety and efficiency during welding tasks. By integrating these features, this clamp guarantees reliable performance, making it an indispensable addition to any welder’s toolkit for consistent grounding and operational safety.