The YESWELDER E7018 Welding Rod is a highly rated choice among both amateur and professional welders, boasting a 4.6 out of 5-star rating. Offered in 3/32″ and 1/8″ diameters, this low-hydrogen iron powder electrode is designed for all-position welding. It produces high-quality x-ray welds, ensuring a steady arc with minimal spatter. Its reliability extends across various applications, including offshore rigs and steel structures, making it a versatile option. What makes this welding rod stand out?

Key Takeaways

- The YESWELDER E7018 Welding Rod offers excellent performance with high-quality x-ray welds and steady arcs for reliable results.

- Available in both 3/32″ and 1/8″ diameters, it caters to various welding needs for amateur and professional users.

- Its low-hydrogen formulation reduces spatter, leading to less cleanup and enhanced efficiency in multi-pass welds.

- Users appreciate its versatility, making it effective for low, medium, and high carbon steels in diverse applications.

- With a customer rating of 4.6 out of 5 stars, it has received positive feedback for ease of use and strong welds.

Overview of YESWELDER E7018 Welding Rod

The YESWELDER E7018 Welding Rod represents a reliable choice for both amateur and professional welders, offering a robust solution for various welding applications.

This low-hydrogen iron powder type electrode, available in 3/32″ and 1/8″ diameters, is designed to excel in diverse welding techniques. Weighing 5 pounds and measuring 14 inches in length, it is suitable for low, medium, and high carbon steels.

Its versatile electrode types make it ideal for tasks ranging from offshore rigs to steel structures. By utilizing the E7018, welders can achieve high-quality results while enjoying the benefits of reduced spatter and improved arc stability.

Performance Features and Benefits

Welders seeking reliable performance will find that the YESWELDER E7018 Welding Rod excels in various critical aspects. This low-hydrogen iron powder electrode type is designed for stick welding, guaranteeing high-quality x-ray welds and steady arcs. Its all-position capability allows versatility across various projects, while its effectiveness on cold rolled steels reduces porosity issues.

| Feature | Benefit |

|---|---|

| High-quality welds | Guarantees structural integrity |

| All-position capability | Versatile for different welding angles |

| Low spatter | Reduces cleanup time |

| Excellent re-striking | Enhances efficiency in multi-pass welds |

| High deposition efficiency | Maximizes productivity |

Ideal Applications for the E7018 Welding Rod

When considering the ideal applications for the YESWELDER E7018 Welding Rod, it becomes evident that its versatility makes it suitable for a range of welding tasks.

This low-hydrogen iron powder electrode excels in various welding techniques. It is particularly effective for low-alloy structurals and carbon steels, making it an excellent choice for offshore rigs, power plants, and steel structures.

Additionally, it performs admirably in tack welding for tubular applications.

The E7018 rod stands out for its all-position capability, allowing welders to tackle diverse projects with confidence, ensuring strong and reliable welds in demanding environments.

Technical Specifications and Details

A thorough understanding of the YESWELDER E7018 Welding Rod’s technical specifications reveals its design and capabilities tailored for effective welding tasks.

This carbon steel stick electrode, with a low-hydrogen iron powder composition, enhances performance across various welding techniques.

Key details include:

- Diameter options: 3/32″ (2.5 lb) and 1/8″ (2.5 lb).

- Recommended amperages: 115A-165A.

- Item weight: 5.19 pounds.

- Package dimensions: 14.02 x 2.83 x 2.52 inches.

Proper electrode maintenance guarantees peak performance, making it suitable for all-position welding on diverse materials, ultimately providing reliable results in various applications.

Customer Feedback and Ratings

Customer feedback and ratings for the YESWELDER E7018 Welding Rod reflect a generally positive reception among users, showcasing its effectiveness in various welding applications.

With an impressive customer rating of 4.6 out of 5 stars, many user testimonials highlight the rod’s steady arc and low spatter, which contribute to high-quality welds.

Customers rave about the YESWELDER E7018 Welding Rod’s steady arc and low spatter, achieving high-quality welds with ease.

Customers appreciate its versatility for both low and high carbon steels, making it suitable for diverse projects.

Additionally, user experiences often mention efficient re-striking capabilities and ease of use.

Frequently Asked Questions

How Should I Store the YESWELDER E7018 Welding Rods?

Welding rod storage should prioritize moisture protection. Store rods in a cool, dry place, preferably in sealed containers or bags. This prevents contamination and maintains the integrity of the electrodes, ensuring peak performance during use.

Can I Use These Rods for Aluminum Welding?

Aluminum welding requires specific rods incompatible with carbon steel stick electrodes. The E7018 electrodes are not designed for aluminum applications, emphasizing the importance of selecting appropriate rod compatibility to achieve successful welding results in aluminum projects.

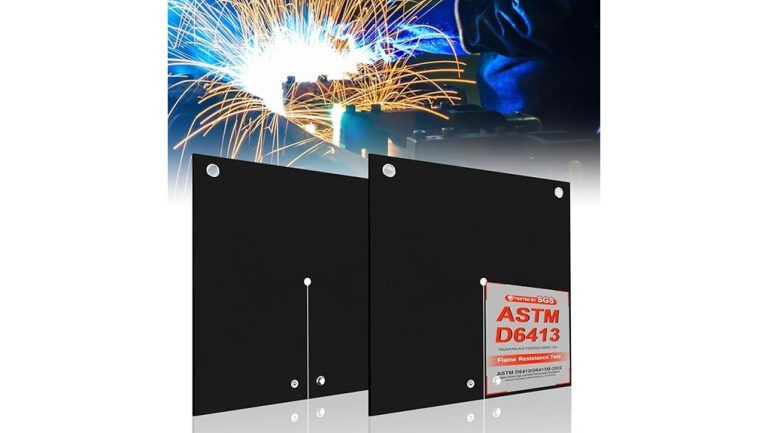

What Safety Gear Do I Need When Using These Rods?

In the domain of molten metal, a brave artisan dons their armor: welding safety goggles, gloves, and flame-resistant clothing. This protective equipment shields against fiery sparks, ensuring their journey through the craft remains unscathed and liberating.

Are These Rods Suitable for Beginners?

These rods are suitable for beginners, providing steady arcs and low spatter, essential for mastering welding techniques. Incorporating beginner tips, they facilitate learning through effective welding practices, enhancing confidence and skill development in the craft.

How Do I Dispose of Used Welding Rods?

Disposing of used welding rods symbolizes the cycle of creation and renewal. One should consider recycling options to responsibly manage welding waste, transforming remnants into resources, fostering a sustainable future while liberating oneself from environmental burdens.

Conclusion

In conclusion, the YESWELDER E7018 Welding Rod stands as a versatile choice for welders seeking reliability and quality. With its low-hydrogen composition and ability to deliver high-quality x-ray welds, it echoes the craftsmanship of master artisans. Its performance in various applications, from offshore to structural welding, solidifies its status as a dependable tool. For both novice and experienced welders, this electrode offers a balanced blend of innovation and tradition, making it a worthy addition to any welding toolkit.