Holiday projects demand versatility, reliability, and a forgiving arc. I wrote this guide because choosing the right welding rod can save you time, reduce wasted material, and help you create clean, lasting holiday gifts and decorations. Whether I’m joining thin sheet metal for a decorative star or building a sturdy frame for a holiday display, the correct electrode matters.

In this article I walk you through 12 rods that cover common metals, skill levels, and budgets so you can pick the one that fits your project and experience.

Top Picks

How I Chose These Welding Rods

I prioritized compatibility with common holiday metals (mild steel, stainless, aluminum), ease of use for hobby welders, and versatility for small decorative and structural projects. I looked for a range of electrode types: E6013 for smooth, forgiving arcs on sheet and light fabrication; E6011 for deep penetration and dirty metal; E7018 for low-hydrogen, higher-strength structural work; and TIG filler rods (ER70S-6, ER308L, ER4043) for clean TIG joins.

I also considered pack size and price for hobbyists, brand reputation, customer rating as a proxy for reliability, and whether a rod is suited to AC or DC machines. For holiday crafting specifically, I weighted ease of strike, slag removal, and appearance higher because finish matters on visible projects.

YESWELDER E6013 3/32″ 5LB

I keep a box of these E6013 rods in my holiday toolbox because they’re just so easy to work with. They’re all-position mild-steel rods that run on AC or DC, which is great when I move between a bench welder and a small inverter.

The rods are 3/32″ by 14″ (5 lb) and like a medium-snip needle — recommended at about 45A–90A, so they’re forgiving for light-gauge metal and patchwork. For seasonal projects — metal wreath frames, little rebar trees, or fixing a rusty sled — the low spatter and clean-sloughing slag make cleanup fast, and the bead looks tidy even with imperfect fit-ups.

I’d recommend these to hobby welders and anyone doing sheet metal or ductwork; they’re not for heavy structural work, but for holiday crafts and everyday repairs they’re reliable and pleasant to use.

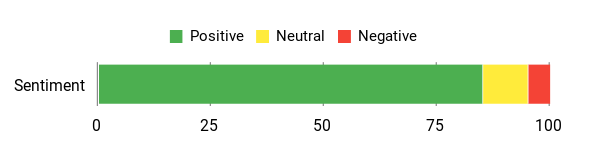

What People Say

People appreciate how forgiving the E6013 rods are: consistent beads, low cleanup, and reliable performance on thin metal and awkward joints. Many hobbyists praise the all-position capability for craft projects.

Overall Sentiment: Positive

🗣️ Weekend Metalworker

Low spatter and excellent slag removal — I noticed much less cleanup on small brackets and metal ornaments. It’s forgiving in vertical down positions, which helped when I was working on a curved wreath frame.

🗣️ Hobby Welder

Works on AC or DC and runs well at lower voltages. I used these on sheet metal holiday decorations and got consistent, attractive beads even on thin pieces.

Durability

Holds up well on light-to-medium tasks like sheet metal, ductwork and decorative builds. Not intended for heavy structural welding, but durable enough for seasonal projects and repairs.

Problem Solving

Great for dealing with poor fit-ups and shallow penetration needs. The rod’s forgiving arc and easy slag release make vertical and awkward joints much less stressful during quick holiday builds.

Key Benefits

- All-position welding for versatility

- Low spatter and easy slag removal for quick cleanup

- Runs on AC or DC — good for different machines

- Forgiving on light-gauge and poorly fitted joints

- Recommended amperage 45A–90A fits hobby setups

Rating: 4.6 (total: 1357+)

WISUNO E6013 3/32″ 1LB

I keep a small can of these WISUNO E6013 rods in my holiday toolbox because they’re straightforward and forgiving. They run on AC or DC and are all-position, which makes swapping between a bench machine and a compact inverter painless. The 3/32″ size is handy for light repairs and craft pieces — think metal wreath frames, tiny rebar trees, or fixing a rusty sled — and the arc starts easily with low spatter so cleanup is quick.

The slag peels off cleanly and the deposited metal meets solid mechanical standards, so the finished bead looks tidy even when my fit-ups aren’t perfect. For seasonal crafts and everyday shop fixes, I find these reliable and easy to use.

What People Say

I’ve noticed people like how forgiving these rods are: consistent beads, less cleanup, and reliable performance on thin metal and awkward joints, which is perfect for craft and light repair work.

Overall Sentiment: Positive

🗣️ Weekend Tinkerer

Low spatter and easy slag removal made cleanup fast when I welded small brackets and holiday ornaments. The arc was stable and forgiving in awkward positions.

🗣️ Holiday Crafter

Ran well on my older AC machine and my inverter on DC. I used these on thin sheet pieces for decorations and got consistent, attractive beads with minimal fuss.

Durability

They hold up well for light-to-medium tasks like decorative builds, small repairs, and sheet metal work. I wouldn’t pick them for heavy structural welding, but they’re durable enough for seasonal projects and home fixes.

Problem Solving

Great for dealing with poor fit-ups and thin materials — the forgiving arc and easy slag release make vertical and awkward joints much easier during quick holiday projects.

Key Benefits

- All-position compatibility for versatile projects

- Runs on AC or DC — good for different machines

- Easy arc initiation and a stable arc for less fuss

- Low spatter and clean slag removal for quick cleanup

- Good for thin plates and light structural patchwork

Rating: 4.7 (total: 72+)

YESWELDER ER70S-6 1/16″x16″ 5LB

I keep a box of these YESWELDER ER70S-6 rods in my shop for seasonal projects and everyday fixes. They run with 100% argon or an argon/helium mix and tend to leave a smoother bead with very little post-weld cleanup, which is great when I’m making holiday metal wreaths, small rebar trees, or patching up rusty garden décor.

They’re forgiving on less-than-perfect fit-ups, so if I’m working on a farm implement or a truck body and the pieces don’t line up cleanly, these rods still lay down solid welds.

If you want something that balances tidy appearance with practical toughness for crafts and general shop work, these are worth trying.

What People Say

Users like the smoother bead and minimal post-weld cleanup, plus how the rods tolerate higher currents and imperfect fit-ups—handy for both craft projects and rougher repair jobs.

Overall Sentiment: Positive

🗣️ Metal Mom

The bead came out smooth with almost no cleanup when I used 100% CO2. I was able to run higher currents without getting a lot of spatter, so finishing my small metal ornaments was quicker than usual.

🗣️ Farmhand Frank

Used these on a rusty trailer bracket and they handled the poor fit-up and surface condition better than my old rods. The deposited metal built up nicely for shaft repair and left a strong, consistent bead.

Durability

These rods deposit metal that holds up well for medium-duty work like farm implements, trailer repairs, and seasonal metal décor. They aren’t meant as a substitute for heavy structural filler wire, but for holiday crafts and general shop maintenance they’re dependable.

Problem Solving

Great at dealing with rusty or poorly aligned joints; the deoxidizers in ER70S-6 help the arc stay stable and reduce spatter, so I spend less time grinding and more time finishing projects.

Key Benefits

- Copper-coated carbon steel for reliable mild steel fabrication

- Works with 100% Argon or Argon/Helium shielding for smoother beads

- Permits higher welding currents with reduced spatter

- Forgiving on poor fit-ups and surface conditions

- Useful for both decorative craft pieces and shop repairs

Rating: 4.7 (total: 820+)

ARCCAPTAIN E7018 3/32″ 5LB

I keep a 5 lb tub of these ARCCAPTAIN E7018 rods around for holiday metal crafts and tougher shop jobs. The low-hydrogen iron powder coating gives a smooth, steady arc and fewer defects, which matters when I’m building metal wreaths, small tree frames, or patching up a gate.

They run on AC or DC reverse polarity and weld well in any position, so awkward fit-ups don’t slow me down. For seasonal decorations and everyday structural touch-ups, they offer a solid balance of clean beads and strong deposits — a practical choice if you want reliability without fuss.

What People Say

Users appreciate the smoother arc, reduced spatter, and strong, crack-resistant deposits—useful for both decorative holiday projects and light structural repairs.

Overall Sentiment: Positive

🗣️ Crafting Chris

These E7018 rods laid a very smooth bead and produced minimal spatter when I was making metal wreath pieces. The low-hydrogen formula seemed to reduce porosity and the welds cleaned up quickly.

🗣️ Garage Greg

I used them to rebuild a small trailer bracket. The deposited metal built up nicely, the welds felt strong, and they handled vertical and awkward positions without hiccups.

Durability

The deposited metal shows high tensile strength and good resistance to cracking, making these rods reliable for medium-duty structural tasks and seasonal metal décor. They’re not a substitute for heavy industrial filler wire but are dependable for gates, frames, and holiday pieces.

Problem Solving

Low hydrogen content helps reduce porosity and hydrogen-induced cracking, and the rods perform well in awkward positions so I can finish tricky joints faster.

Key Benefits

- Low-hydrogen iron powder formula for fewer defects

- Smooth, stable arc with less spatter

- High tensile strength and good resistance to cracking

- Usable in any welding position with AC or DC reverse polarity

- Suitable for carbon steel and low-alloy steel, including some medium-carbon steels

Rating: 4.6 (total: 325+)

YESWELDER ER308L Stainless TIG Rod 1/16″x16″ 5LB

I keep a box of these YESWELDER ER308L rods in the shop for holiday metal projects and everyday stainless work. They’re the go-to when I need a filler that resists intergranular corrosion — the low carbon content gives me cleaner-looking welds on things that might see moisture or food contact.

I use them on small decorative frames, custom ornaments, and when I’m patching stainless brackets or kitchen hardware. They like 100% argon (or argon/helium if I want a bit more penetration and speed), and they’re forgiving enough for awkward positions during quick craft sessions. If you want a reliable stainless TIG rod for seasonal décor and light-to-medium stainless repairs, these are a solid pick I reach for often.

What People Say

Users frequently note the corrosion-resistant weld metal and compatibility with common stainless grades, plus good performance with argon shielding for clean beads suitable for decorative and functional pieces.

Overall Sentiment: Positive

🗣️ Workshop Wendy

Worked well on a few stainless ornament frames I welded for the holidays. Using 100% argon gave good penetration and the beads cleaned up without heavy discoloration.

🗣️ Seasonal Sam

I used these for a small repair on stainless kitchen hardware. The low carbon content felt noticeable — less staining after welding and confidence that the joint will resist corrosion over time.

Durability

With a low maximum carbon content, ER308L deposits resist intergranular attack better than higher-carbon alternatives. For holiday décor, kitchen fixes, and light structural stainless work, the welds hold up well; for heavy industry you’d still choose specialized filler, but this is dependable for most shop and craft needs.

Problem Solving

These rods help avoid post-weld corrosion issues on stainless parts and respond well to argon-based shielding, giving me better penetration when I need it. That makes finishing faster and reduces rework on seasonal projects and small repairs.

Key Benefits

- Low carbon composition for improved resistance to intergranular corrosion

- Designed for TIG filler use on common stainless alloys (304/308/321/347)

- Responsive with 100% argon or argon/helium shielding for better penetration

- Good for both decorative holiday projects and light industrial repairs

- Produces clean welds that are easier to finish and polish

Rating: 4.7 (total: 820+)

50 Pieces Flux Core Aluminum Rods

I keep a pack of these AZB flux-core aluminum rods around for holiday crafting and quick shop repairs. They melt at a lower temperature than some fillers and the built-in flux means I don’t have to juggle separate solder powder or paste.

I use them for small ornaments, decorative frames, patching thin aluminum trim and even resurfacing a few scuffed pieces of outdoor décor. They won’t replace TIG for precision stainless work, but for casual seasonal projects and on-the-spot aluminum fixes they save time and simplify setup. If you want an easy-to-use rod for festive metal crafts and light aluminum repairs, these are a handy option I reach for often.

What People Say

People appreciate the convenience of the built-in flux and the easy-melt behavior — it’s repeatedly called out as a timesaver for ornaments, small repairs, and hobby projects. Most users find it straightforward to use for non-structural aluminum work.

Overall Sentiment: Positive

🗣️ Crafty Claire

No extra solder or flux to mix — I was able to tack and fill several small aluminum ornaments in one afternoon. The rods melted predictably and saved me a lot of prep time when making holiday decorations.

🗣️ Homefix Hank

Used these to patch a dented aluminum step and to rework a couple of garden stakes. The low melting point made welding quicker and cleanup wasn’t terrible. Good for lightweight repairs and seasonal projects.

Durability

In my experience these rods produce welds that hold up well for décor and light repairs. They aren’t intended for heavy structural loads, but for holiday pieces, frames, and small outdoor bits the joints have been reliable when done carefully.

Problem Solving

These rods solve the common hobbyist problem of needing extra flux or complex setup: flux is in the core, so I can get from prep to weld faster. They’re especially useful when I need quick, practical joins on aluminum without switching to TIG or buying separate flux.

Key Benefits

- Flux-cored design — no separate solder powder required

- Low melting temperature makes it easier for hobbyists

- Suitable for aluminum, aluminum alloys and aluminum-magnesium alloys

- Good weldability and decent corrosion resistance for decorative projects

- Convenient pack size for multiple craft sessions

Rating: 3.7 (total: 514+)

YESWELDER E7018 3/32″ 10LB

I keep a box of these YESWELDER E7018 rods in the shop for both routine fixes and seasonal projects. They’re low-hydrogen, which means fewer headaches with cracking and cleaner structural welds when I’m joining carbon steel for gates, frames, or even heavier holiday décor. The rods run well in all positions and have a steady arc with low spatter, so I spend less time grinding and more time finishing pieces.

For casual crafting I’ll use them to tack and stitch together metal ornaments, decorative signs, or custom wreath frames; for tougher jobs they’re solid for medium- to high-carbon steels and light structural work. Specs I pay attention to: 3/32″ diameter, 14″ length and recommended amperage around 70–100 A, which fits my standard stick setup.

If you want a dependable, general-purpose rod that scales from quick seasonal projects to real shop repairs, these are the ones I reach for.

What People Say

People note the consistent arc, reduced spatter and reliability across positions — useful both for shop repairs and seasonal metal crafts. Many find the low-hydrogen chemistry makes a difference on structural joints.

Overall Sentiment: Positive

🗣️ WeldingWendy

Steady arc and very low spatter — I was able to make clean tack welds on a steel wreath frame and didn’t have to chase a lot of slag afterward. Re-strikes were easy and the bead looked consistent across vertical and overhead passes.

🗣️ ShopSteve

Used these for repairing a rusty porch railing and for some holiday metal stars. The rods handled medium carbon steel without preheat and I noticed less porosity compared with conventional electrodes. Good deposition and a solid feel under my stick welder.

Durability

From my experience the welds made with E7018 feel robust for structural and decorative pieces. They’re the kind of rods I trust on railings, frames and outdoor décor when the joint needs to last through weather and handling.

Problem Solving

These rods address common stick welding issues: they cut down porosity on cold-rolled steels, minimize spatter so there’s less cleanup, and the low-hydrogen coating helps prevent weld cracking in service. For holiday builds that mix aesthetics and some load-bearing joints, they solve the need for a reliable, easy-to-manage electrode.

Key Benefits

- Low-hydrogen formula reduces cracking on structural welds

- All-position usability for flat, vertical and overhead work

- Steady arc with low spatter and good re-striking ability

- High deposition efficiency for quicker builds and repairs

- Suitable for carbon steels and some low-alloy steels

Rating: 4.6 (total: 1357+)

YESWELDER E6011 3/32″ 5LB

I keep a pack of these E6011 rods in my toolbox when I expect to deal with rusty, painted, or otherwise less-than-perfect metal — they’re forgiving. The cellulose coating gives a forceful, digging arc that makes root passes and repair work easier, and they run well on standard stick welders.

For holiday crafting I use them when I need strong penetration on reclaimed metal for wreath frames, rustic ornaments, or when tacking together salvaged steel for light outdoor décor. They’re not the prettiest bead for fine decorative seams, but for structural tacks, repairs and quick seasonal builds they get the job done reliably. If you want something that handles grime and still makes solid joints, these are worth keeping around.

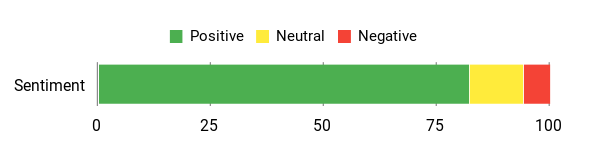

What People Say

Users highlight the rods’ ability to cut through rust and scale, producing strong, reliable joints for repairs and reclaimed-metal projects. Many mention the energetic arc and dependable penetration.

Overall Sentiment: Positive

🗣️ FixItFrank

I used these to repair an old metal sled and then welded up a rustic tree frame from scrap pieces. The rods dug into the rusty spots and produced a solid root with good penetration — I didn’t have to spend ages grinding or pre-cleaning everything.

🗣️ HolidayMaker

Ran them on my 120 A stick welder for some outdoor candle holders made from reclaimed pipe. The arc stayed energetic and re-strikes were straightforward. Not the prettiest beads for show pieces, but the joints feel strong and dependable.

Durability

Welds laid with E6011 tend to have solid penetration and feel robust for light structural and repair work. For holiday decorations that might see some handling or outdoor exposure, the joints hold up well when tacked and fused properly.

Problem Solving

These rods solve the common issue of welding less-than-pristine steel: the cellulose coating helps the arc dig in so you can weld through rust or paint without extensive prep. That makes them great for quick seasonal builds using reclaimed parts.

Key Benefits

- Deep penetration ideal for root passes and repairs

- Performs well on rusty, painted or dirty metal

- Works on common stick welders and standard power settings

- Good re-strike ability for intermittent welding

- Useful for structural tacks and reclaimed-material projects

Rating: 4.6 (total: 1357+)

ARCCAPTAIN E6013 3/32″ 5LB

I keep a pack of E6013 rods around for holiday projects where I want tidy-looking beads without fuss. These run on AC or DC and are forgiving on low-voltage machines, so they’re great for crafting thin-sheet ornaments, welding wreath frames, fixing metal candle holders, or tacking up small outdoor decorations.

The arc starts smoothly and spits less slag, which means less cleanup and more time actually finishing pieces. For quick seasonal builds and home-shop projects where fit-ups aren’t perfect, they make the job relaxing rather than finicky.

I’d recommend them for hobbyists and anyone who wants an easy-to-use rod that still gives a neat finish.

What People Say

We often hear that these rods are easy to run and leave tidy beads, making them a favorite for holiday crafts and light repair work where appearance matters.

Overall Sentiment: Positive

🗣️ WeldFan89

The rods start easily and run well on my older AC machine. I liked how little spatter they made and that slag came off cleanly — saved me time on finishing holiday ornaments.

🗣️ CraftsByMe

Used these for thin-steel tree ornaments and small furniture repairs. They handled poorly fitted joints without fuss and produced stable, attractive beads for decorative pieces.

Durability

I find E6013 welds hold up well for decorative and light-structural uses. They’re not for heavy structural loads, but joints for wreath frames, ornaments and small outdoor décor stay solid when welded correctly.

Problem Solving

These rods handle common hobby-shop problems — they tolerate less-than-perfect fit-up and still give a stable arc, plus the low spatter reduces cleanup time when I’m on a deadline for seasonal projects.

Key Benefits

- Smooth arc start that’s beginner-friendly

- Works on both AC and DC machines

- Minimal spatter and easy slag removal

- Good for thin plates and mild steel

- Performs well on imperfect fit-ups

Rating: 4.6 (total: 325+)

SONNLER ER4043 Aluminum TIG Rod 3/32″

I reach for ER4043 when I’m welding aluminum decorations or fixing thin panels around the house. The 5% silicon makes the puddle run nicer, which helped me when I TIG-welded small sled brackets and holiday ornaments without fighting the bead. It behaves predictably under 100% argon (or argon/helium mixes), gives a stable arc, and keeps spatter low — handy when I don’t want a long cleanup session. There are three common diameters, so I pick the size to match tacks versus filler runs.

For seasonal crafts, garden décor, or light repair work on 3000–6000 series alloys, this rod is a reliable, easy-to-live-with option I’d recommend to hobbyists and home-shop welders.

What People Say

We often hear that these rods run smoothly and make aluminum work less fussy — users appreciate the fluid puddle and low spatter, which speeds up finishing for decorative and light-repair projects.

Overall Sentiment: Positive

🗣️ AlumCrafter

The 5% silicon really made a difference for me — the weld pool flowed smoothly and I experienced fewer hot cracks while joining 6061 panels for a small sled. The arc stayed steady using 100% argon and cleanup was quick thanks to minimal spatter.

🗣️ TIGHomeShop

Used these rods to TIG a batch of tree ornaments from 5052 sheet. The puddle was predictable, which kept the thin pieces from warping, and the 3/32″ size was great for tacking and filling without fuss.

Durability

I find ER4043 welds hold up well for decorative items and light structural pieces around the yard. They’re not my pick for critical structural or high-stress applications, but for ornaments, frames, and small repairs they stay solid when welded with proper technique.

Problem Solving

This rod helps solve common hobby-shop headaches: less sensitivity to cracking, a forgiving puddle that tolerates modest fit-up issues, and minimal spatter so I spend less time grinding before painting or assembling.

Key Benefits

- Improved melt-pool fluidity from 5% silicon

- Stable arc with low spatter for cleaner finishes

- Compatible with many aluminum alloys (3003, 5052, 6061, etc.)

- Available in multiple diameters for tacking or filling

- Works well with 100% argon or argon/helium mixes

Rating: 4.6 (total: 137+)

YESWELDER E6013 3/32″ 2LB

I reach for E6013 when I need a forgiving stick rod for holiday projects and small repairs. It runs on AC or DC and plays nicely on low-voltage AC machines, so I don’t have to fuss with power settings for simple jobs. The rod is all-position and gives relatively shallow penetration, which is perfect for thin-gauge metal, sheet-metal ornaments, and duct work where I want control rather than brute force.

I like the low spatter and the way the slag peels off — that saves time when I’m making multiple decorative pieces or quick fixes. For seasonal crafting, light structural tack-ups, and any time I need a neat-looking bead without excessive cleanup, this is a dependable option I recommend for hobbyists and home-shop welders.

What People Say

We hear that users appreciate how clean the rod runs — low spatter and removable slag make finishing faster, and the all-position performance helps when fit-up isn’t perfect.

Overall Sentiment: Positive

🗣️ SheetMetalSam

Low spatter and excellent slag removal made cleanup quick when I welded small decorative frames and brackets. The rod behaved well in vertical-down fillets and produced a tidy bead.

🗣️ WeekendWelder

Worked well on my low-voltage AC machine and handled poor fit-ups without a fuss. Great for light gauge metal and duct work — predictable and easy to control for seasonal projects.

Durability

For decorative items, light repairs, and seasonal craft pieces, the welds hold up well when done with proper technique. Because E6013 gives shallower penetration, I avoid it for critical structural joints that need deeper fusion.

Problem Solving

This rod solves common hobby-shop headaches: it’s forgiving on poor fit-ups, works on basic AC machines, and keeps cleanup to a minimum thanks to low spatter and self-cleaning slag behavior.

Key Benefits

- All-position rod for versatile hobby and shop use

- Runs on AC or DC and tolerates low-voltage AC machines

- Low spatter and easy slag removal for faster cleanup

- Good for thin-gauge metal, sheet metal, and duct work

- Recommended amperage range (45A–90A) suits small projects

Rating: 4.6 (total: 1357+)

ARCCAPTAIN E7018 1/8″ 10LB

I keep E7018 rods in my shop when a project needs dependable, crack-resistant welds. These iron-powder, low-hydrogen electrodes run well on AC or DC reverse polarity and hold a smooth, stable arc that makes it easier for me to lay consistent beads. For holiday crafting I use them when I want strong tack-ups on heavier stock — think metal tree frames, outdoor decorations, or small structural repairs to garden art.

They’re also the kind of rod I reach for on tougher jobs: bridges, trailers, or anything that benefits from higher tensile strength and good x-ray values. If you want a versatile stick that tolerates different positions and gives predictable, low-spatter results, this is one I’d recommend adding to your lineup.

What People Say

We hear that users value the stable arc and low spatter for faster cleanup, plus the rod’s ability to produce tough, crack-resistant welds on medium to high carbon steels.

Overall Sentiment: Positive

🗣️ MetalMaker

The rod gives a smooth, stable arc with less spatter and good melting efficiency — cleanup was noticeably quicker while I welded some metal holiday signs and brackets.

🗣️ ShipwrightChris

I used these on thicker carbon steel pieces and liked the resistance to cracking and solid fusion; worked well in different positions and on both AC and DC machines.

Durability

When welded with proper technique (and preheat where needed), E7018 joints hold up well for structural and outdoor projects. It’s a solid choice for pieces expected to bear load or face weather, though attention to storage and dryness helps maintain performance.

Problem Solving

This rod addresses common shop headaches: it lowers hydrogen-related cracking, gives consistent deposition in multiple positions, and performs reliably on both AC and DC power — useful when you’re switching machines or tackling fit-up issues.

Key Benefits

- Low-hydrogen formula reduces risk of hydrogen-induced cracking

- Iron-powder coating for higher deposition and smoother arc

- All-position capability for vertical and overhead holiday builds

- Works on AC or DC reverse polarity for flexible machine use

- Suitable for carbon steels and some medium-carbon/low-alloy steels

Rating: 4.6 (total: 325+)

FAQ

How Do I Choose The Right Rod For Holiday Crafting Projects?

I start by thinking about the metal I’m working with and the look and strength I want. For general mild steel craft pieces I often reach for E6013 because it’s forgiving and easy to strike, while E7018 is my go-to when I need a stronger, low-hydrogen weld for joints that must hold up over time. If I’m welding stainless steel for decorative ornaments I prefer ER308L, and for aluminum pieces I use aluminum TIG rods like ER4043 or flux-core aluminum rods when I need portability and no external gas. The key is to match the rod to the base metal and to pick a diameter that fits the sheet thickness and your machine’s amperage; a small assortment of E6013, E7018, ER70S-6 (for TIG/MIG filler), ER308L and an aluminum rod covers most holiday projects.

Can I Use These Rods For Small Decorative Pieces And What Technique Or Safety Tips Should I Follow?

Yes — many of the rods in a typical 12-rod kit are great for small decorative work, but you need to pick the right process. I use E6013 for light sheet-metal ornaments because it leaves a smooth bead and is tolerant of quick passes; for thin aluminum I switch to TIG with an ER4043 rod to control heat and avoid burn-through.

Flux-core rods are handy outdoors because they don’t need shielding gas, but they make more spatter and a rougher finish. For technique and safety I always wear proper PPE, keep my welds short to manage heat and distortion, tack pieces before completing a seam, clean the metal (especially for stainless and aluminum), and practice on scrap to dial in amperage and travel speed.

Also remember that some rods, especially E7018, must be handled carefully to retain performance.

How Should I Store And Prepare Welding Rods To Avoid Porosity And Cracking?

I treat storage and preparation as part of the project because moisture and contamination are the main causes of porosity and cracking. I keep rods dry in sealed containers with desiccant or a purpose-built rod oven; for low-hydrogen electrodes like E7018 I use a heated storage oven when possible and re-bake electrodes that have been exposed to humidity. Before welding I clean the base metal of paint, oil and rust, and I file or brush stainless and aluminum surfaces to remove oxides.

If a rod has absorbed moisture, I’ll follow the manufacturer’s bake procedures before use rather than risk brittle welds or porosity.

Customer Favorites

When choosing between the YESWELDER E6013 3/32 5LB, WISUNO E6013 3/32 1LB and YESWELDER ER70S-6 1/16×16 5LB, I focus on electrode type, quantity and the job at hand — E6013 sticks are popular for easy arc starts and forgiving repairs on slightly dirty metal, while ER70S-6 is picked when I want a cleaner, stronger MIG-style deposit for shop or structural work. We usually prioritize ease of use and weld control, how much material we need (1 lb for occasional touch-ups versus 5 lb for regular projects), compatibility with our equipment and base metal, and overall value from a trusted brand.

Wrapping Up

Pick the rod that matches your metal and skill level to get the best results. For general holiday crafting I often reach for an E6013 because it’s forgiving and produces a clean bead on thin sheet metal. If I need strength or am welding structural pieces, I use E7018; for stainless and aluminum I switch to the appropriate TIG filler rod.

Choosing the right rod improves appearance, reduces rework, and helps you finish projects faster. Use the top picks above as a starting point and match the spec to your welder and the metal you’re joining.

This Roundup is reader-supported. When you click through links we may earn a referral commission on qualifying purchases.