When considering a plasma arc cutting machine, you’ll appreciate its precision and speed, with tolerances as tight as 0.2 mm and rapid cutting capabilities. It efficiently handles various conductive materials like stainless steel and aluminum. However, challenges arise with thicker materials, where cut quality diminishes, and the risk of warping due to heat becomes prevalent. The initial investment and specialized consumables can be significant. Safety measures are essential due to noise and intense light exposure.

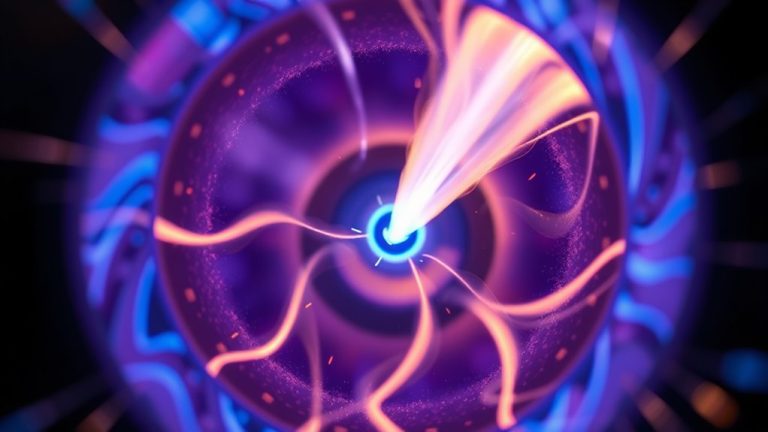

Understanding Plasma Arc Cutting Technology

When you explore plasma arc cutting technology, you’ll find it harnesses the power of ionized gas to achieve remarkable precision and speed in cutting conductive materials. The process begins by ionizing compressed air or gases, creating a plasma arc reaching over 20,000°C. This intense heat efficiently melts metals, allowing for clean cuts with tolerances as low as 0.2 mm, particularly when using CNC plasma systems.

Plasma arc cutting uses ionized gas to deliver precision and speed, achieving clean cuts with remarkable accuracy.

Plasma cutting is versatile, effectively slicing through stainless steel, aluminum, copper, and brass. It handles thicknesses up to 50 mm, making it ideal for various applications.

One of its key advantages is the minimal heat-affected zone (HAZ), which maintains the material’s integrity and mechanical properties. However, it’s important to recognize potential disadvantages, such as the initial investment in equipment and the need for proper ventilation due to fumes.

Nevertheless, with operational costs as low as $3 per hour, it remains a cost-effective solution.

Key Benefits of Plasma Arc Cutting

Plasma arc cutting offers numerous advantages, making it a preferred choice in many industrial applications. Primarily, plasma cutting provides precision cuts with tolerances as tight as 0.2 mm, ideal for intricate designs in metal fabrication.

Its ability to cut through a wide range of materials, including carbon steel, stainless steel, aluminum, and copper, expands its utility across various sectors. The cutting speed of plasma systems surpasses traditional methods, boosting efficiency and minimizing the stress on workpieces due to reduced heat exposure.

Another key benefit is the minimal heat-affected zone (HAZ) generated by plasma cutting. This feature helps maintain the material’s integrity, reducing warping and distortion, vital when working with thicker materials.

Operating costs are also advantageous, averaging around $8/hour for electricity and consumables, making it a cost-effective solution. Despite the disadvantages of plasma, such as initial investment, these benefits make it a superior choice for clean cuts in metal fabrication.

Challenges and Limitations of Plasma Arc Cutting

Although plasma arc cutting presents numerous benefits, it’s important to acknowledge the challenges and limitations that accompany its use.

The plasma cutting process struggles with cut quality on thick materials, specifically those over 50 mm. This limitation makes it less suitable for heavy industrial applications compared to flame or waterjet cutting. Additionally, the process creates a significant heat-affected zone, which can alter the mechanical properties of sensitive metals, potentially causing warping.

Plasma cutting’s cut quality diminishes on materials over 50 mm, leading to potential warping.

High initial investment and operational costs are other hurdles, as the equipment requires specialized consumables like electrodes and gases, which can be costly.

Furthermore, the intense light and bright flashes produced demand strict eye protection, while noise levels ranging from 90 to 120 decibels necessitate hearing protection to prevent hearing damage.

These challenges highlight the importance of carefully considering the trade-offs involved in adopting plasma arc cutting for specific applications.

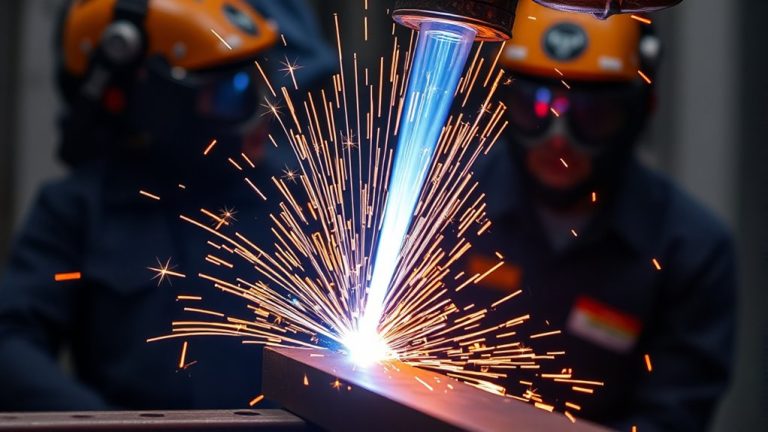

Safety Measures in Plasma Arc Cutting

Understanding the challenges and limitations of plasma arc cutting underscores the significance of implementing stringent safety measures. Safety training is vital for operators. It guarantees familiarity with operational protocols, enabling effective risk mitigation.

Plasma cutting generates noise levels between 90 to 120 decibels (dB), so hearing protection is mandatory to prevent hearing damage. Protect yourself from intense light and sparks by wearing protective eyewear and clothing. Hazardous fumes are another concern; make certain your workspace has proper ventilation and exhaust systems to maintain air quality.

Incorporating automated plasma-cutting cobots can further enhance safety by minimizing direct human exposure to hazards. They follow safety protocols, reducing the likelihood of accidents.

Always prioritize setting up a secure environment when working with plasma arc cutting machines. By adhering to these safety measures, you’ll protect yourself and maintain operational efficiency, guaranteeing a safer and more productive cutting process.

Selecting the Right Plasma Arc Cutting Machine

How do you confirm that you’re selecting the best plasma arc cutting machine for your needs? Analyze key factors like maximum thickness, material compatibility, and duty cycle. Most plasma cutting systems excel at cutting materials up to 50 mm thick for carbon and stainless steel and 40 mm for aluminum. Evaluate versatility in handling various conductive materials to guarantee cutting quality isn’t compromised.

Consider initial investment and operational costs. Plasma cutters generally offer lower consumable expenses compared to laser systems, making them cost-effective for thicker materials. Portability and ease of setup are essential; choose a lightweight model for greater flexibility across different worksites.

Here’s a quick comparison to aid your decision:

| Feature | Importance |

|---|---|

| Maximum Thickness | Determines material suitability |

| Material Compatibility | Guarantees versatility across metals |

| Duty Cycle | Impacts long-term productivity |

| Initial Investment | Affects budget considerations |

| Portability | Enhances operational flexibility and efficiency |

Select wisely to optimize performance and cost-efficiency.

Frequently Asked Questions

What Are the Advantages of Plasma Arc Cutting?

You’ll appreciate plasma arc cutting for its cutting speed, precision cuts, and versatility across applications. It’s cost-efficient, safe for operators, and offers low maintenance requirements. Its energy consumption is moderate, plus portability and technological advancements enhance usability for varying material thickness.

What Are the Advantages and Limitations of Plasma Arc Machining?

Plasma arc machining offers speed efficiency with cuts up to 500 inches per minute. You’ll appreciate its material versatility. However, consider cost analysis and power consumption while ensuring safety features. Operator skill impacts cut quality and maintenance requirements.

What Are the Disadvantages of Plasma Arc Cutting?

You’re facing safety concerns with high noise levels and intense light. Operational costs rise due to power requirements and maintenance needs. Material thickness limits cut quality. Training is essential, while portability issues and environmental impact can’t be ignored.

Is It Worth Getting a Plasma Cutter?

Yes, it’s worth getting a plasma cutter if your projects require fast, precise cuts. Consider plasma cutter benefits like cutting speed and material compatibility, but analyze cost, maintenance, and safety. Ascertain project suitability and explore portability options.

Conclusion

In the domain of metal fabrication, plasma arc cutting machines are a double-edged sword. They slice through materials with surgical precision and speed, yet demand a hefty investment and careful handling. While these machines shine on thinner metals, they struggle with thicker challenges, risking warping and quality loss. Prioritize safety—like guarding against a dragon’s fiery breath—when operating. Choose wisely, focusing on your specific needs, to harness their full potential while mitigating drawbacks.