You might think plasma arc cutting is too complex, but it’s straightforward with the right guidance. This process uses a high-temperature plasma jet to slice through conductive materials. By ionizing gas, you create a plasma arc reaching temperatures over 40,000°F. Understanding how cutting speed, arc current, and gas pressure affect the cut quality is essential. Explore how these elements interact and improve your cutting precision and efficiency.

Understanding the Basics of Plasma Arc Cutting

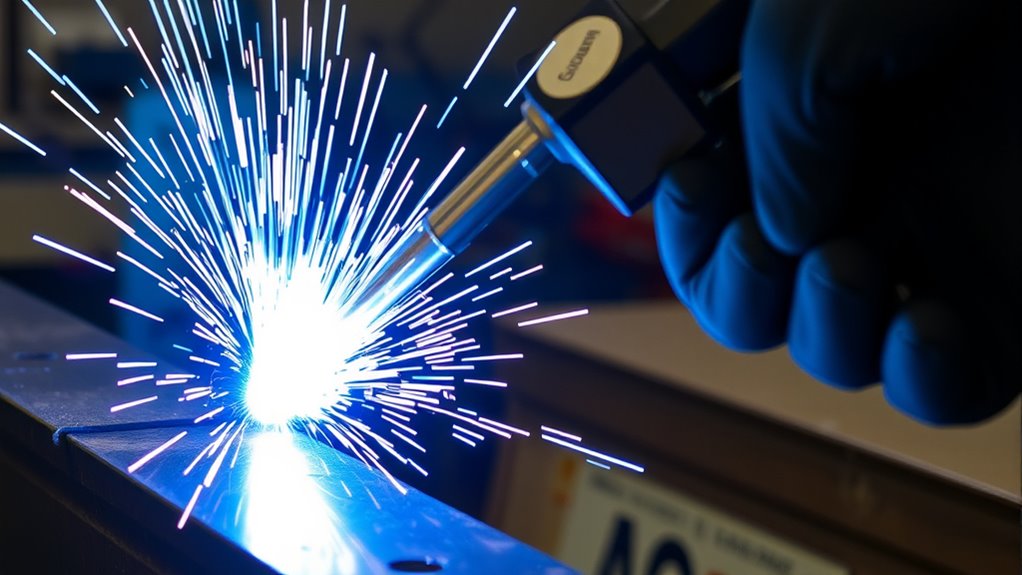

Plasma arc cutting, a powerful fabrication method, utilizes a high-temperature jet of ionized gas to slice through electrically conductive materials.

Harness the power of plasma arc cutting to efficiently slice through electrically conductive materials with precision.

In this plasma cutting process, you’ll direct gases like oxygen or nitrogen through a nozzle, creating an electric arc that ionizes the gas. This forms a plasma jet capable of melting and cutting metals at temperatures soaring up to 40,000°F.

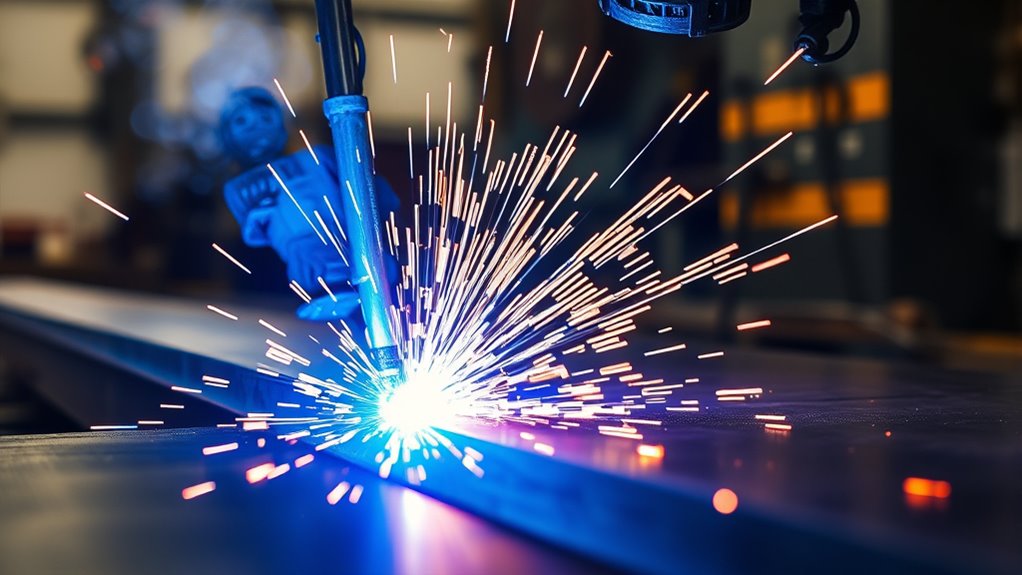

You’ll find CNC plasma cutters particularly effective for achieving quality cuts at impressive speeds, reaching up to 20 inches per minute on materials as thick as 50 mm.

Despite producing a wider kerf than laser cutting, plasma arc cutting excels in versatility, handling various metals including stainless steel, aluminum, and copper with ease.

However, remember to prioritize safety; the high temperature and potential fumes necessitate protective gear and adequate ventilation.

Mastering this technique allows you to efficiently tackle numerous industrial applications.

The Science Behind Plasma Formation

When you heat a gas like argon or nitrogen to extremely high temperatures, it undergoes ionization, freeing electrons from atoms and forming a potent mixture of ions and free electrons known as plasma.

In plasma arc cutting, this plasma jet can reach temperatures up to 40,000°F, allowing it to efficiently melt through electrically conductive materials.

Ionization of Gas Explained

Although the process may seem complex, understanding the ionization of gas is essential to grasping the science behind plasma formation. When energy, whether as heat or electrical current, is applied to a gas, it undergoes ionization. This process separates electrons from atoms, forming an ionized gas.

In plasma arc cutting, here’s what happens:

- Gas Ionization: Gases like argon or nitrogen are ionized, transforming them into plasma.

- Initiating Plasma Arc: A high-frequency spark ionizes the gas, creating a path for electrical current.

- Conductive Materials: The plasma arc allows electrical current to flow through, heating to high temperatures.

- Efficient Cutting Process: These high temperatures, reaching up to 40,000°F, enable efficient cutting through conductive materials by melting them.

Plasma Jet Characteristics

Understanding the characteristics of a plasma jet is essential to mastering the plasma cutting process. A plasma jet forms when an electric arc ionizes a high-pressure gas, like oxygen or argon, creating a stream of ionized gas at temperatures over 40,000°F.

This jet is forced through a nozzle, reaching high velocities and current densities up to 50,000 amps/in², which greatly boosts cutting speed and quality. The intense heat allows the plasma jet to melt electrically conductive materials, while the rapid movement of gas expels molten metal, ensuring clean cuts.

Incorporating a swirl ring in precision torches constricts the plasma arc, enhancing cutting performance by reducing kerf width and improving overall precision.

Key Components of Plasma Cutting Systems

To understand plasma cutting systems, focus first on the power supply, which converts AC line voltage to provide the 200-400 VDC necessary for cutting.

Next, examine the torch, which is designed to house essential consumables like the electrode, swirl ring, and nozzle that collectively generate and direct the plasma jet.

These components work in tandem to guarantee efficient and precise cutting, forming the backbone of any reliable plasma cutting system.

Power Supply Functionality

When examining the power supply functionality in plasma cutting systems, you’ll find it essential for converting AC line voltage into a high DC voltage, typically ranging from 200 to 400 VDC, to create the necessary plasma arc.

This high voltage is vital for generating the arc that will interact with the plasma gas, ensuring ideal cutting quality.

In conventional systems, shop air is often used as the plasma gas, whereas precision setups might require multiple gases for enhanced results.

Consider these key points:

- Voltage Conversion: AC to high DC voltage.

- Arc Generation: Initiated by high-frequency AC.

- Gas Utilization: Conventional vs. precision systems.

- Cutting Efficiency: Depends on current density variations.

A well-functioning power supply directly influences your cutting system’s performance and efficiency.

Torch Design Essentials

In a plasma cutting system, the torch design plays a critical role in ensuring efficient and precise cuts. The plasma torch comprises key components like the electrode, swirl ring, and nozzle. The electrode, often made from hafnium or zirconium, initiates the spark to ionize the gas, forming a plasma jet. The swirl ring creates a gas flow vortex, stabilizing the cutting arc. The nozzle constricts and directs this plasma flow onto the work piece, ensuring precise cuts with minimal heat-affected zones.

| Component | Function |

|---|---|

| Electrode | Generates the initial spark and ionizes the gas. |

| Swirl Ring | Creates a vortex of gas flow for stability. |

| Nozzle | Constricts and directs plasma flow precisely onto the work piece. |

| Configuration | Utilizes varying gas compositions and current densities for optimized cutting of different material types and thicknesses. |

The Plasma Cutting Process Explained

Mastering the plasma cutting process involves understanding its core principle: creating a plasma jet by ionizing a chosen gas with an electric arc. This jet reaches temperatures over 20,000°F, efficiently melting materials like stainless steel.

The process begins with a high-frequency spark that initiates a pilot arc. This ionizes the gas, establishing a continuous arc when the torch contacts the workpiece. The plasma jet not only melts but also blows away molten material, enabling precision cutting.

Here’s how it works:

- Gas Ionization: Air, nitrogen, or argon is ionized by the arc.

- Heat Generation: The arc heats the plasma to extreme temperatures.

- Material Penetration: Plasma cuts through metals like stainless steel, aluminum, and copper.

- Molten Material Removal: The jet blows away melted material, ensuring clean cuts.

Factors like cutting speed, arc current, and gas pressure directly impact cut quality, highlighting the process’s precision and efficiency.

Advantages and Limitations of Plasma Cutting

Though plasma cutting is a versatile and efficient method for slicing through electrically conductive materials, it’s essential to understand both its advantages and limitations. This process uses heat to melt metals and is effective on carbon steel, stainless steel, aluminum, and copper. It excels at cutting thick metals, with some machines handling material thicknesses up to 150 mm. The cutting machine provides high-quality cuts for medium thicknesses, making it cost-effective for certain industrial applications.

However, plasma cutting has a larger heat-affected zone (HAZ) and produces wider kerfs compared to laser cutting. This can result in less precise tolerances, especially on thinner materials. Traditional plasma systems may struggle with very thin sheets where laser cutting is preferable.

Advanced systems using multiple shielding gases can enhance precision and cleanliness but still mightn’t match the thickness capabilities of waterjet or flame cutting methods, which are better suited for extreme thicknesses.

Selecting the Right Cutting Method for Your Needs

When choosing the right cutting method for your project, how do you guarantee excellent results? Start by evaluating the material type and thickness. For carbon and stainless steel, plasma cutting is ideal up to 50 mm, while aluminum should be limited to 40 mm.

Consider the following factors:

- Material Type: Plasma cutting excels with both ferrous and non-ferrous metals. For thinner sheet metal, laser cutting might be preferable.

- Accuracy Requirements: If high accuracy and repeatability are necessary, opt for CNC plasma cutting. This method provides cleaner cuts compared to manual techniques.

- Cost-Effectiveness: For medium-thickness applications starting at 15 mm, plasma cutting is often quicker and more economical.

- Gas Selection: Use inert gases like argon or nitrogen to enhance cut quality over using air.

Safety Measures and Best Practices in Plasma Cutting

To guarantee safety and efficiency during plasma cutting, prioritize wearing appropriate personal protective equipment (PPE) such as a shade #5 or #8 helmet, leather gloves, and flame-resistant clothing.

Wear PPE like a shade #5 or #8 helmet, leather gloves, and flame-resistant clothing for plasma cutting safety.

These safety measures protect against arc eye and burns from sparks and hot metal. Verify your work area is clean and free of flammable materials, as sparks can travel up to 1.5 meters (5 feet).

Proper ventilation is vital to disperse harmful fumes generated during cutting, protecting your health.

Regular equipment maintenance is essential. Inspect your plasma cutter regularly and replace consumable electrodes and nozzles promptly to confirm peak performance and safety.

Training is paramount for safe operation. Make sure you’re well-versed in handling plasma cutters to reduce the risk of accidents and enhance cutting efficiency.

Innovations and Future Trends in Plasma Technology

As plasma technology continues to evolve, the industry witnesses an exciting array of innovations poised to enhance cutting precision and efficiency.

High tolerance plasma arc cutting (HTPAC) is at the forefront, delivering precision cuts for materials under 12mm thick, providing a cost-effective alternative to laser cutting. The incorporation of high-frequency transistor inverters in inverter plasma cutters greatly enhances performance, reducing size and weight for greater efficiency.

Innovations in plasma torches and nozzle design are enabling smaller, more focused plasma arcs, achieving near-laser precision and reducing the need for post-cut processing.

The integration of CNC technology further revolutionizes plasma arc cutting, allowing for automated, complex shapes with unmatched speed and accuracy. These technological advancements are complemented by ongoing research into alternative plasma gases, broadening material compatibility.

Key advancements include:

- High tolerance plasma arc cutting (HTPAC)

- High-frequency inverter plasma cutters

- Advanced plasma torch and nozzle designs

- CNC technology integration

Frequently Asked Questions

What Is the Process of Plasma Arc Cutting?

You initiate plasma arc cutting by ionizing gas to create a plasma jet. Guarantee material compatibility, consider cutting speed, and follow safety precautions. Regular machine maintenance and cost considerations are vital for effective plasma technology applications.

What Are the Two Primary Types of Plasma Arc Cutting?

The two primary types are conventional and precision plasma cutting. You’ll appreciate their mechanical advantages, thermal efficiency, and safety protocols. Guarantee equipment maintenance to optimize industry applications, while considering cost implications for your specific cutting needs.

What Is the Plasma Arcing Method?

You utilize the plasma arcing method in various plasma technology applications to achieve cutting speed efficiency. Choosing the right electrode materials is essential. Always follow safety precautions and consider costs for industrial uses to maximize effectiveness.

What Are the Disadvantages of Plasma Arc Cutting?

Imagine plasma arc cutting as a powerful dragon: it requires strict safety precautions, diligent equipment maintenance, and thorough cost analysis. Material compatibility is essential, while operator training tames its fire. Beware its environmental impact; it’s no gentle creature.

Conclusion

So, you’ve mastered the art of wielding a jet of 40,000°F ionized gas, slicing through metal like a hot knife through butter. Marvel at your newfound powers, but don’t forget the hazards—after all, you’re not just toasting marshmallows here. As you navigate through cutting speed dilemmas and arc current conundrums, remember: safety gear isn’t just for fashion. Embrace the plasma arc cutting world, where precision meets pyrotechnics, and every project feels like a sci-fi adventure.