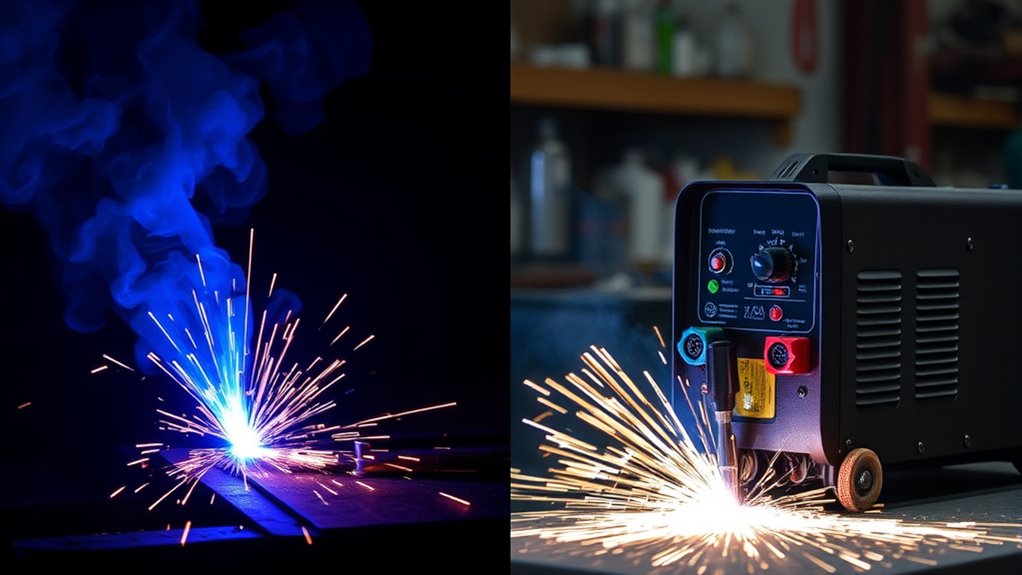

When you explore how a pilot arc plasma cutter operates, you’ll find it generates a low-energy arc that ionizes plasma gas, creating a high-temperature jet before touching the workpiece. This technique allows for efficient metal cutting without pre-drilling, enhancing precision and minimizing dross. Its applications span automotive to aerospace, offering rapid, clean cuts. Pilot arc technology also reduces safety risks, making it indispensable. Curious about its advantages and applications? Keep discovering.

Understanding Pilot Arc Plasma Cutting

When you’re working with a pilot arc plasma cutter, understanding its operation is essential for ideal performance.

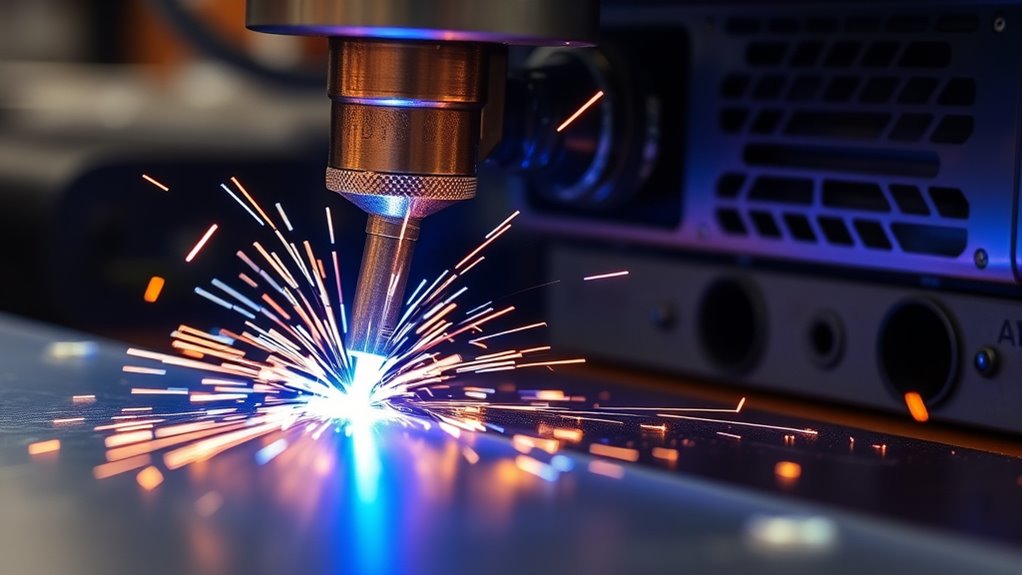

Pilot Arc Starting is an important feature of plasma cutting systems, as it initiates the cutting process by generating a low-energy electrical arc between the electrode and nozzle. This method allows you to cut through metal surfaces, including those that are rusty or painted, without pre-drilling holes, enhancing efficiency and versatility.

In these systems, the pilot arc is formed in a two-stage process, ensuring a stable arc before contact with the workpiece. This technique greatly improves cut quality by reducing dross and providing cleaner edges.

Modern plasma cutting systems have advanced to mitigate the risks of high-frequency arcs to sensitive electronics, enhancing their reliability in industrial settings. With their ability to handle uneven surfaces and challenging materials, pilot arc plasma cutters deliver consistent performance in demanding environments.

Mechanisms of Pilot Arc Formation

You initiate the pilot arc by activating the plasma cutter’s trigger, which sends a high-voltage current through the plasma gas, forming a low-energy arc before it touches the workpiece.

Be aware of potential high-frequency arc issues, such as electromagnetic interference, which can affect nearby electronic devices.

This pilot arc method guarantees arc stability and allows you to cut through challenging surfaces, like painted or rusty metal, with precision and efficiency.

Pilot Arc Initiation Methods

Although various methods exist to initiate a pilot arc in plasma cutters, the underlying goal remains the same: efficient arc formation between the electrode and workpiece. Each type of plasma cutter utilizes a specific starting method tailored to its design.

The high-frequency method in pilot arc plasma cutters involves generating a high-voltage arc through the air, though it requires careful handling due to potential interference with electronics.

Capacitive discharge methods effectively initiate arcs by releasing energy bursts that spark arc transfer without direct contact.

Spring-loaded designs, on the other hand, rely on creating a short circuit through pressure, ensuring reliable pilot arc formation.

Modern initiation techniques enhance safety, reducing electrocution risks and minimizing maintenance compared to older systems.

High-Frequency Arc Issues

Even though high-frequency (HF) arc initiation is a staple in pilot arc plasma cutters due to its precision, it presents several challenges.

When the arc is initiated using high frequency, it relies on high voltage and spark gaps to ionize the air between the electrode and nozzle. This creates a low-energy arc, enabling precise cuts without contacting the workpiece.

However, this method can risk electrocution and disrupt sensitive electronic equipment nearby. Additionally, maintaining spark gaps is essential, as their degradation can lead to inconsistent performance.

Newer technologies aim to reduce HF emissions and the maintenance burden. Despite these issues, the HF method remains important for cutting through painted or rusted metal, offering advantages in complex industrial environments.

Arc Stability Advantages

Addressing the challenges posed by high-frequency arc initiation, pilot arc plasma cutters capitalize on the arc stability mechanism to enhance cutting performance.

The plasma arc is initially formed between the electrode and nozzle, creating a preemptive stable arc before contacting the workpiece. This two-stage arc initiation process guarantees consistent arc stability throughout the cutting process, allowing you to cut through painted, rusty, or dirty surfaces effortlessly.

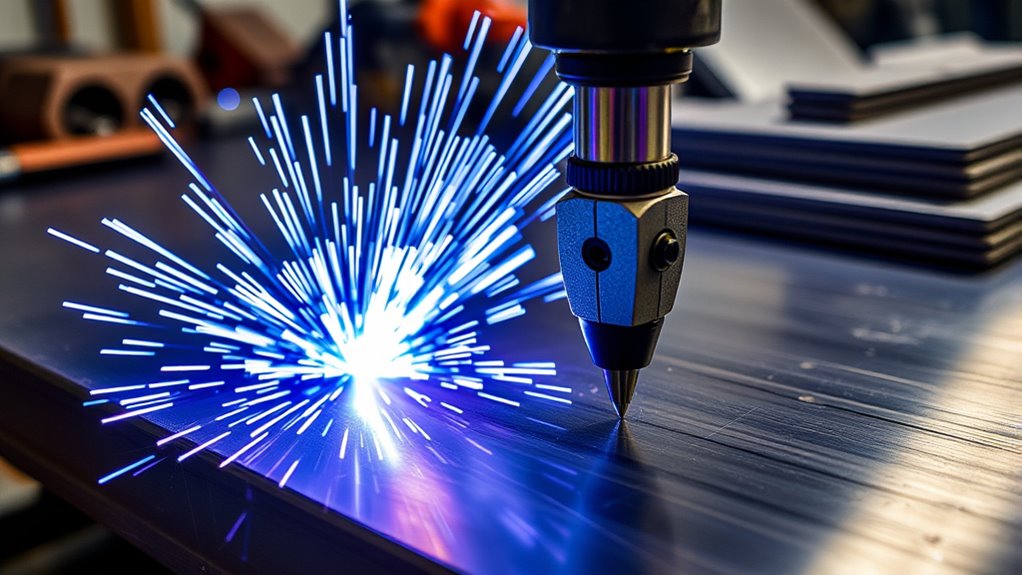

The separation of the electrode and nozzle generates a low-energy pilot arc, ionizing the gas and forming a plasma jet capable of reaching high temperatures up to 40,000°F. This continuous plasma flow maintains a stable arc, enabling smoother operation even at varying speeds and angles.

Consequently, pilot arc plasma cutters enhance precision and efficiency in diverse cutting scenarios.

Key Advantages of Using a Pilot Arc Plasma Cutter

When considering the advantages of using a pilot arc plasma cutter, you’ll find that its innovative technology greatly enhances cutting efficiency and versatility. This tool employs a high-frequency pilot arc, which delivers quality cuts even on challenging surfaces like painted or rusty metal. This means you can achieve precision without needing to clean or drill pre-holes, streamlining your workflow and saving valuable time.

The ease of use is further amplified by its ability to maintain a consistent arc, reducing the likelihood of interruptions during cutting operations.

Moreover, the pilot arc’s HF-free starting method minimizes the risk of damaging nearby sensitive electronic equipment, making it safer for diverse environments. It’s particularly advantageous in industrial settings where precision and speed are paramount.

The plasma cutter’s ability to produce cleaner cuts with less heat-affected zones compared to traditional methods enhances both the accuracy and quality of your work, making it an indispensable tool.

Applications in Various Industries

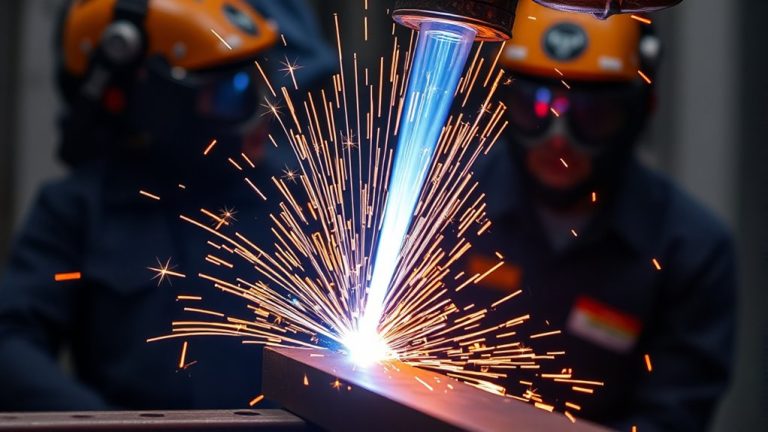

In diverse industries, pilot arc plasma cutters play a pivotal role in enhancing productivity and precision.

Within the automotive sector, plasma cutters use a cutting arc capable of slicing through rust and paint, eliminating the need for pre-drilling holes and streamlining the process of shaping metal components.

In aerospace, these tools are indispensable for achieving precise cuts on lightweight yet durable materials such as aluminum and titanium—essential for aircraft fabrication.

Construction projects benefit from the plasma cutter’s efficiency, enabling rapid cutting of steel beams and structural components, even in confined spaces.

Metal fabrication shops capitalize on the cutting arc’s ability to produce intricate designs and custom parts, thanks to its high speed and minimal heat-affected zones, preserving the integrity of the work piece.

In shipbuilding, pilot arc plasma cutters efficiently manage thick metal plates, ensuring clean welds essential for assembling robust ships.

Comparison With Non-Pilot Arc Plasma Cutters

Though both pilot arc and non-pilot arc plasma cutters are designed to achieve precise metal cuts, essential differences in their operation can greatly affect performance and usability.

Pilot arc cutters initiate cutting with a high-frequency arc, allowing stable performance even on painted or rusty surfaces. This ability to pierce without pre-drilled holes gives them a clear advantage over non-pilot arc models that require direct contact to establish the arc, often struggling with such tasks.

Here’s a quick comparison:

- Cutting Performance: Pilot arc excels on uneven surfaces.

- Surface Compatibility: Works on painted/rusty areas without issues.

- Cost: Pilot arc models are pricier due to advanced technology.

- Portability: Non-pilot arc units are typically more lightweight.

- Safety: Pilot arc reduces electric shock risk with high-frequency initiation.

Opt for a pilot arc cutter if consistency and versatility across various surfaces are your priorities; non-pilot arc models are suitable for basic, cost-effective operations.

Essential Components in a Pilot Arc System

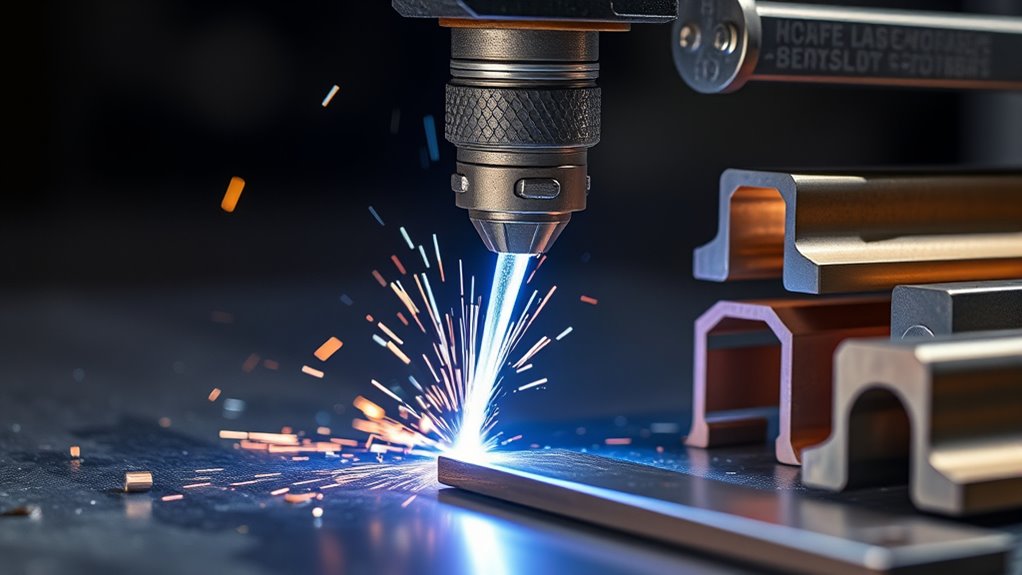

Understanding the unique advantages of pilot arc plasma cutters requires examining the key components that make up the system. At the heart of the system is the power supply, which converts standard AC line voltage into high DC voltage, allowing an arc to be established between the electrode and nozzle in the plasma torch. This process is essential for generating the intense heat needed to cut through metal.

The arc starting console plays an important role by producing high-frequency AC voltage, necessary for ionizing plasma gas flow through the torch and initiating the pilot arc. This guarantees stable cutting performance, even on challenging surfaces like painted or rusty metals.

Within the plasma torch, consumables such as the electrode, swirl ring, and nozzle are meticulously designed to align and cool the plasma jet. The system typically uses shop air or specific gases to create a plasma jet reaching temperatures up to 40,000°F, enabling efficient metal piercing and cutting.

Safety Considerations and Best Practices

When operating a pilot arc plasma cutter, prioritizing safety is essential. To protect yourself from potential hazards, always use safety glasses and other protective gear. High temperatures and flying debris can pose serious risks, so proper attire is vital.

Additionally, the ultraviolet radiation produced during cutting requires eye protection to prevent damage.

Ensure you’re working in a well-ventilated area. Plasma cutting can release harmful fumes and gases, especially from coated or painted metals. Adequate ventilation helps to minimize inhalation risks.

Familiarize yourself with the cutter’s user manual and follow manufacturer safety guidelines. This knowledge greatly enhances safe and effective operation.

Here’s a checklist for safe plasma cutter operation:

- Wear safety glasses and protective gear to shield against debris and radiation.

- Operate in a well-ventilated area to avoid inhaling harmful fumes.

- Follow the user manual thoroughly.

- Adhere to manufacturer safety guidelines.

- Regularly inspect and maintain your equipment.

Maintaining Your Pilot Arc Plasma Cutter

To guarantee your pilot arc plasma cutter operates at peak efficiency, it’s important to maintain it meticulously.

Start by regularly inspecting and cleaning the torch and consumables; debris buildup can hinder performance and degrade cut quality. Replace consumables like electrodes and nozzles as per the manufacturer’s guidelines to secure precision and efficiency.

Regularly clean and inspect the torch and consumables to prevent debris buildup and maintain optimal cut quality.

Monitoring the gas flow is critical; maintaining the correct flow rates and pressures prevents overheating and supports stable arc performance.

Periodically, check the high-frequency starter and spark gaps for any wear or damage since these components are essential for initiating a reliable arc.

Make sure the power supply and all connections remain dust-free and dry, as dust and moisture can cause electrical issues, compromising functionality.

Choosing the Right Plasma Cutter for Your Needs

How do you choose the right plasma cutter for your needs? Begin by deciding if a pilot arc model fits your cutting tasks, especially if you’re dealing with rusty or painted metals. A pilot arc cutter offers superior performance on uneven surfaces.

Focus on adjustable amperage to enhance versatility. For example, the FORCECUT 40D provides 40 Amps and can switch between 110V and 220V power sources, accommodating various tasks.

Consider these factors:

- Cutting Thickness: Check if the plasma cutter can handle your material’s thickness, as pilot arc models excel with thicker materials.

- Torch Compatibility: Opt for a torch like the S-45, which enhances precision and is compatible with pilot arc models.

- Consumables Availability: Guarantee easy access to replacement parts to minimize downtime.

- Operational Environment: If sensitive electronics are nearby, select HF-free models to reduce RF interference.

- Power Source Flexibility: Versatile power options increase operational convenience.

Future Trends in Plasma Cutting Technology

Although the current landscape of plasma cutting technology is robust, future advancements promise to revolutionize the field further.

You’ll see a notable push towards energy efficiency, focusing on reducing power consumption and adopting eco-friendly gases. This shift not only lowers operational costs but also aligns with environmental sustainability goals.

Smart technologies, such as IoT and machine learning, will play an essential role by enabling real-time monitoring and predictive maintenance, thereby minimizing downtime and enhancing operational efficiency.

Automation and robotics will enhance precision and speed, boosting industrial production rates.

Meanwhile, HF-free arc starting methods will continue to evolve, reducing interference with sensitive electronic equipment and improving safety.

Expect emerging designs to feature advanced materials and coatings, greatly increasing durability and performance.

This evolution leads to longer-lasting consumables and reduced maintenance needs, ensuring that plasma cutting remains a reliable and efficient tool in various industrial applications.

Frequently Asked Questions

How Does the Pilot Arc Work?

You initiate the pilot arc using the arc initiation process, where thermal dynamics ionize the gas, forming plasma. This guarantees plasma stability, allowing you to cut through conductive materials efficiently, even over rust or paint.

What Is the Difference Between Pilot Arc and Non Pilot Arc Plasma Cutters?

Imagine cutting through butter with a hot knife; that’s a pilot arc’s advantage over non-pilot arc cutters. Pilot arc guarantees cutting efficiency on challenging surfaces, while non-pilot arc applications suit simpler tasks but lack precision on thicker materials.

What Is the Difference Between a Touch Arc and a Pilot Arc Plasma Cutter?

A touch arc plasma cutter requires direct contact with the metal, limiting its cutting techniques on uneven surfaces. In contrast, a pilot arc plasma cutter uses a non-contact arc, offering superior precision and versatility across various materials.

What Are the Disadvantages of Plasma Arc Cutting?

You’ll face cost factors with high initial expenses, safety concerns from hazardous fumes needing ventilation, and complex maintenance requirements for components. These issues can make plasma arc cutting less ideal for some industrial applications.

Conclusion

In summary, a pilot arc plasma cutter is your go-to tool for precision and efficiency in metal fabrication. By understanding its mechanics and applications, you can cut through challenges like a hot knife through butter. Its benefits—minimal dross, safety enhancements, and versatility—make it indispensable across industries. Regular maintenance will keep it in tip-top shape, ensuring it meets your cutting needs. Stay ahead of the curve by choosing the right cutter and embracing future advancements.