What Is a Butt Joint Used For?

One of the first joints I learned to weld in the shop was the butt joint, and at the time I didn’t realize how important it would be in real-world fabrication. Whether you’re running MIG on mild steel, TIG on…

One of the first joints I learned to weld in the shop was the butt joint, and at the time I didn’t realize how important it would be in real-world fabrication. Whether you’re running MIG on mild steel, TIG on…

Brazing HVAC copper lines can feel high-pressure—one tiny leak costs time, refrigerant, and money. This guide focuses on heat balance, joint prep, nitrogen purging, and filler techniques that consistently produce clean, leak-free joints in real-world installs. Clean and prep the…

Running flux core welds can sometimes leave behind those frustrating worm tracks — little surface trails that make a bead look messy and weak. Many welders confuse it with poor arc control, but the real issue often comes down to…

I had to fix a leaking HVAC copper pipe on a jobsite without using traditional soldering—it threw me off at first. I’d spent years running beads with stick, MIG, and TIG on everything from stainless to mild steel, but brazing…

When I first started running beads with a stick welder, one of the biggest questions that threw me off was, “should you push or pull stick welding?” What seemed like a small detail quickly proved to be a make-or-break factor…

Thin sheet warps fast and blows through even faster. With the right rod, polarity, and travel, stick welding thin metal is not only doable—it’s practical for field repairs and small shops. To stick weld thin sheet metal, use small-diameter E6013…

When I first stepped onto an oil rig as a welder, I remember staring at the thick steel plates, TIG torch in hand, and wondering, “Just how much does a rig welder make an hour?” After years of wrestling with…

First time I tried to weld stainless steel with a stick welder — I was confident, but the reality hit fast. The arc kept running too hot, my bead looked messy, and the stainless warped more than I expected. That’s…

One of my early shop days took a sharp turn when I nearly tripped over a poorly stored oxygen cylinder while moving my MIG rig across the floor. At the time, my head was buried in figuring out arc control,…

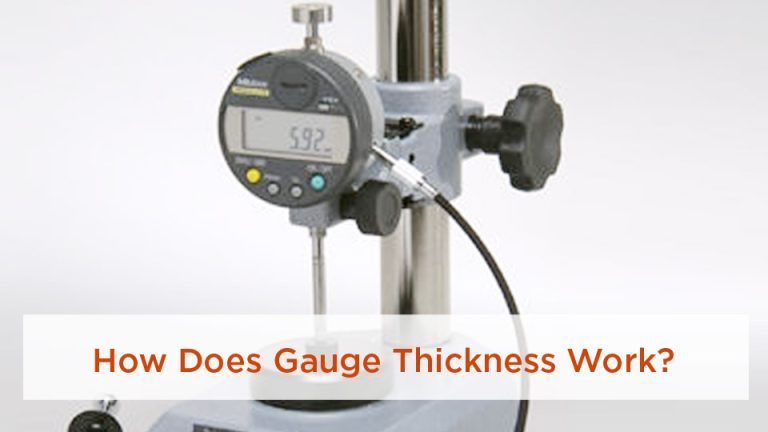

I burned through a thin sheet of stainless because I didn’t fully understand how gauge thickness worked. I had my MIG dialed in, filler wire ready, but the arc control was all over the place — and that one mistake…