🔧 Why a Homemade Jigsaw Table Makes Sense

I built a simple jigsaw table because I wanted a compact, affordable, and powerful way to cut precise curves and small shapes without hauling out a large bandsaw or coping saw. A jigsaw table turns a handheld jigsaw into a stationary tool that can improve accuracy and repeatability for many woodworking and metalworking tasks, but it also requires additional safety measures (guards, clamps, and a proper power switch).

🛠️ What you need: Materials and tools

Keep the parts list minimal. I used what I had on hand and focused on strength and flatness.

- Materials

- Sheet of 12 mm plywood or MDF for the table top

- Steel or plywood rails for the fence

- Angle iron or flat steel for mounting a jigsaw shoe (if using welded mounting)

- Bolts, nuts, washers, and T-nuts or wing nuts for adjustable parts

- Rubber feet or leveling bolts

- Optional: MDF insert ring for blade clearance or dust collection collar

- Tools

- Handheld jigsaw (obviously)

- Drill and bits

- Clamps

- Metalworking tools or a welder if you plan to fabricate a steel mounting plate

- Router or chisel to cut a flush slot for the jigsaw shoe if needed

🔩 Design goals and measurements

My priorities were a flat top, easy jigsaw mounting, and an adjustable fence. Typical small table size is 500 mm by 350 mm (≈ 19-11/16 in. by 13-3/4 in.), but choose a size that fits your workspace. The most important dimension is the clearance under the table so the jigsaw blade can move freely without hitting supports.

🧰 Step by step build

1. Build the tabletop

Cut the plywood or MDF to size and ensure the top is flat. If you want dust collection, cut a circular or oval opening (≈38–50 mm / 1-1/2–2 in.) near the blade position for a dust port. Reinforce the underside with battens so the top does not flex.

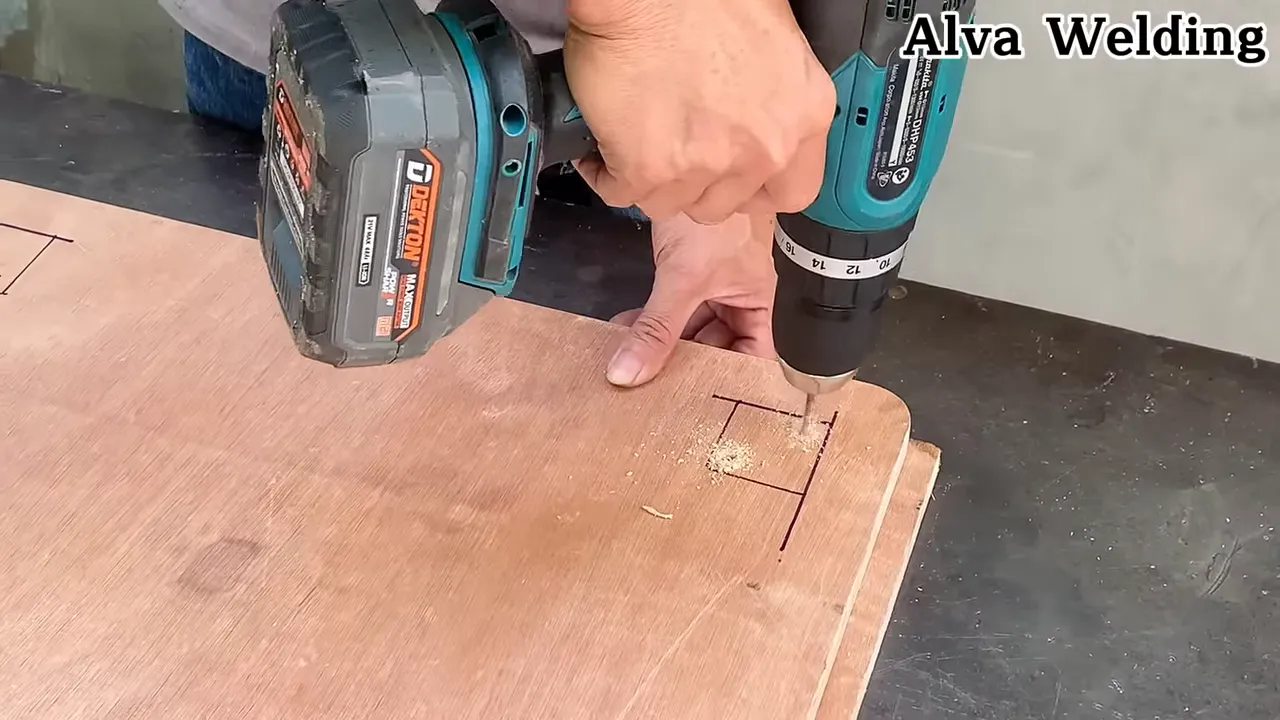

2. Prepare the jigsaw mounting

There are two common methods: bolt the jigsaw through its shoe into the underside of the table, or make a removable steel bracket that clamps the jigsaw in place.

- If bolting through the shoe, mark and drill holes that match the jigsaw shoe, then attach with bolts and washers from below. Make sure the blade aligns perfectly with the table slot.

- If welding a plate, cut and tack an angle or plate that mates flush with the jigsaw shoe and weld mounting points. Test the alignment before final welding. If you do not weld, fabricate a simple bolt-on bracket from flat steel.

3. Cut the blade slot

Cut a narrow slot in the tabletop for the blade to pass through. A router or a narrow saw blade works well. Leave a slightly larger opening at the front for easy blade changes if you plan to remove and replace blades frequently.

4. Add a fence and hold-downs

Attach adjustable rails or a straight fence to the top. Use T-nuts or slots so the fence can slide. Add a hold-down clamp (e.g., toggle clamps) or sacrificial fence for small pieces so they do not lift when cutting curves.

5. Final adjustments and leveling

Fit rubber feet or leveling bolts. Check that the blade is perfectly perpendicular to the table for clean cuts. Finish edges and sand to remove sharp corners.

🔍 Tips and tricks I learned (so you don’t regret it)

- Make the blade slot replaceable by using a thin sacrificial insert. That way you can replace the slot if it gets damaged.

- Use a zero-clearance insert around the blade for better support on thin workpieces and cleaner cuts.

- Keep the jigsaw shoe firmly supported under the table to prevent wobble that ruins accuracy.

- Use a dust port near the slot and a vacuum to keep the cutting line visible and reduce heat buildup in the blade.

- If you weld, tack first and test alignment before final welds. Heat can warp your mount if you are not careful.

⚠️ Safety and maintenance

Always disconnect power before making adjustments or removing the jigsaw. Use a no-volt release (NVR) switch or foot switch so the tool cannot auto-restart after power loss, and check your manual—inverted mounting may void the warranty. Check bolts and mounts regularly. Replace dull blades; a sharp blade reduces binding and blade wander and improves finish. If you welded metal parts, inspect welds for cracks or fatigue over time.

🔄 Variations and upgrades

Depending on your needs, the jigsaw table can be customized:

- Add a miter gauge slot for angled cuts.

- Make a foldable or removable top for storage in small shops.

- Integrate a no-volt release (NVR) switch or foot switch to control power within easy reach.

- Use a stiff, flat metal plate (e.g., 4–6 mm steel or 6–8 mm aluminum) for a more precise seat for the jigsaw shoe when making intricate cuts.

📌 Summary: Why this is worth building

This homemade jigsaw table gives you a compact, versatile cutting station that dramatically improves your ability to make clean curves, inlays, and small precision parts. It is inexpensive, customizable, and quick to build using basic materials and tools. I really regret not learning about this setup sooner because it speeds up many projects and makes tricky cuts much easier.

❓FAQ

What size should my jigsaw table be?

Choose a tabletop that fits your workspace; 500 mm by 350 mm works well for small to medium projects. More important than overall size is ensuring there is enough clearance under the table for the jigsaw to move and for your hands to work safely.

Do I need to weld anything to build this table?

No. Welding is optional. You can bolt the jigsaw shoe to the underside of the table or build a bolt-on steel bracket. Welding helps make a compact, sturdy mount but is not required.

Can I use any jigsaw model?

Most handheld jigsaws will work. Check the shoe mounting pattern and ensure the blade aligns with your table slot. Some jigsaws have offset shoes or nonstandard mounting that require a custom bracket.

How do I handle dust collection?

Cut a dust port near the blade opening and attach a shop vac. A sealed or nearly sealed dust collection around the slot dramatically reduces debris and keeps your cut line visible.

What blade should I use for the cleanest cuts?

Use a fine-tooth blade designed for the material you are cutting. For wood, choose blades labeled for clean cuts or scrolling. For metal, use a metal-cutting blade rated for the thickness of your material.