When you plan a 4×8 ft work envelope to handle full sheets, you avoid costly re-indexing and workflow bottlenecks. You’ll size the frame, pick a CNC‑ready plasma unit, match compressor CFM, and choose CAD/CAM like AutoCAD and Mach3. Then you’ll spec linear rails, steppers, a Z float, and a downdraft or water table. Costs swing with materials and motion hardware. Set a baseline budget now—or risk design dead-ends and performance compromises later.

Planning Your Table Size, Capacity, and Budget

Start by defining the work envelope: a 4×8 ft table lets you process full sheets and minimizes material handling.

Lock in table dimensions early; a standard 4×8 footprint balances workspace, floor space, and sheet utilization.

Lock in dimensions early—a standard 4×8 footprint optimizes workspace, floor space, and full-sheet utilization.

Validate gantry travel and torch reach to cover the full bed without overtravel.

Specify cutting thickness targets next. Design for at least 1/4 in steel to guarantee versatility; confirm the frame, slats, and motion system can support the mass and thermal load of thicker plate.

Create a budget baseline around structure, motion, and safety.

Allocate the largest share to the frame, linear rails, drive hardware, cable management, and a rigid water or downdraft base.

Plan for a removable cutting surface to speed maintenance and prolong accuracy.

Add a downdraft system if you need improved fume control.

Include PPE and shop tools—welding gear, protective eyewear, flame-resistant jacket—to keep fabrication and operation safe and compliant.

Essential Components, Software, and Tools

You’ll spec the core hardware first: a plasma cutter with matched air compressor, a CNC motor control package driving a gantry, and a rigid table base built from 2×2 and 2×3 tubing, plus a downdraft system plumbed with 10-inch HVAC ducting.

You’ll run CAD/CAM with AutoCAD or Fusion 360 for design, SheetCAM for toolpaths, and Mach3 for machine control.

You’ll assemble with a metric Allen key set, wire strippers, an engineer’s square for axis alignment, and strict PPE—shade 5 eyewear and flame-resistant clothing.

Core Hardware Components

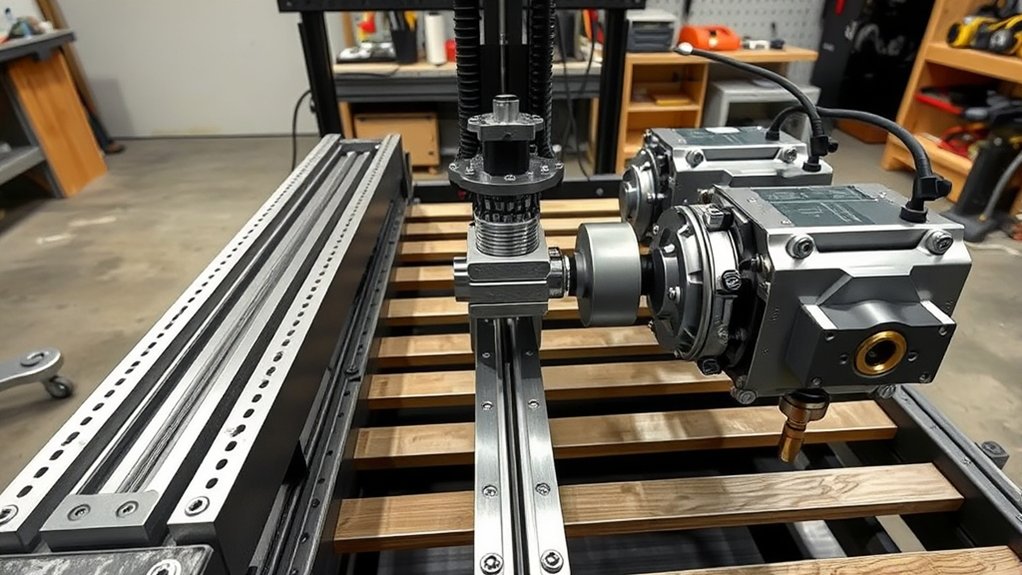

Hardware defines the machine’s capability: your core stack combines a CNC‑ready plasma cutter (e.g., Hypertherm Powermax 65 or Everlast PM256), a dry, stable air supply via a properly sized compressor, a CNC motor control package (drivers, power supply, motion controller), a rigid gantry assembly with linear guides, and a stout, leveled table base for stiffness and vibration control.

Prioritize plasma cutter selection for CNC interface compatibility, reliable arc start, and consumable availability. Specify 90–120 psi, clean/dry air with adequate CFM; include filtration and a dryer to protect the torch.

Engineer the gantry assembly design for low deflection: use supported rails, preload bearings, and balanced mass to maintain acceleration. Choose NEMA‑23/34 steppers or servos matched to inertia.

Level, triangulate, and brace the table to damp vibration.

Recommended Cad/Cam Software

Why does software choice matter as much as steel and steppers? Because your workflow lives or dies on CAD software, CAM software, and control.

Use AutoCAD or Fusion 360 for precise 2D sketches; their constraints and layers drive design precision and clean CNC commands. Feed DXF files into SheetCAM, which excels at plasma cutting with efficient toolpath generation, lead-ins, kerf compensation, and cut rules.

Drive the machine with Mach3; its user interface exposes feeds, pierce delays, and THC signals while ensuring software compatibility across the chain. Follow the instructional video and software tutorials for setup, and keep software updates current to prevent post issues.

- Sharp lines snapping to constraints

- Toolpaths spiraling into clean pierces

- An M-code stream pacing motion

- A DRO tracking smooth arcs

Essential Safety Tools

Sparks demand discipline: before cutting, kit yourself with shade 5 eyewear to filter plasma arc radiation, a flame‑resistant jacket to shed spatter, and sturdy gloves to prevent burns and cuts. Treat this safety gear as mandatory, not optional.

Add protective eyewear side shields, leather boots, and ear protection to control noise and hot debris. Keep a Class ABC fire extinguisher within arm’s reach and maintain clear egress.

For assembly accuracy and safe operation, use a metric Allen key set to torque fasteners, an engineer’s square to verify frame squareness, and wire strippers to prepare clean electrical terminations.

Source components from Amazon for availability and standardization. Choose CNC‑compatible cutters like the Everlast PM256 or Hypertherm PowerMax 65. Implement a floating head to maintain torch standoff automatically, preventing tip crashes and workpiece gouging.

Building the Table Base and Cutting Surface

Start by sizing the frame to suit extended gantry rails and 4x8ft sheets, using 2x2x11ga square and 2x3x11ga rectangular tubing for stiffness, alignment, and load capacity.

Integrate drop-down casters without compromising torsional rigidity, and account for enclosure panels that preserve airflow for a downdraft system.

Design a removable slat bed compatible with downdraft or a water table, ensuring quick extraction for maintenance and precise support spacing to control kerf clearance and warpage.

Frame Materials and Dimensions

Although designs vary, you’ll get a rigid, shop-ready base by building the frame from 2x2x11ga square tubing with 2x3x11ga rectangular tubing in high-load rails and crossmembers, sized for a full 4×8 ft cutting envelope.

This section thickness balances frame stability and material durability while keeping mass manageable for accurate motion. Lay out the perimeter to 49×97 in to clear sheet tolerances, then place 2×3 members under gantry tracks and mid-span supports to cap deflection under dynamic loads.

- Clean, square tube joints aligned on a flat surface

- Welded gussets at leg-to-rail nodes

- Drop-down casters integrated into corner plates

- Aluminum sheet panels enclosing lower bays

Target a 34–36 in working height. Pre-drill leveling pad plates. Keep the cutting surface removable, and plan fastener patterns that won’t interfere with rail mounting.

Removable Slat Bed

With the frame squared, welded, and set to a 34–36 in working height, focus on a removable slat bed that drops into the 49×97 in opening and supports full 4×8 sheets. Build the pan from aluminum sheet to contain debris and channel air to a downdraft plenum. Slot the rails to accept adjustable slats; vary spacing and height to suit material thickness and stabilize parts. Removable slat benefits include rapid swap-out, improved cut access, and consistent airflow. For slat maintenance, standardize slat width and keep a labeled spare set. Integrate drop-down casters in the base for repositioning without racking.

| Component | Spec | Purpose |

|---|---|---|

| Slat material | Mild steel, 3/16–1/4 in | Rigidity, longevity |

| Pan material | Aluminum sheet | Dust containment |

| Slat spacing | 2–4 in adjustable | Part support |

| Downdraft | 600–1000 CFM | Fume extraction |

Gantry, Z-Axis, and Motor Control Assembly

Precision begins at the gantry. Build the gantry assembly from rigid extruded aluminum, square and shim it so the rails remain parallel along X and Y. Use low-friction V-wheels or linear guides and tensioned belts to minimize backlash.

The Z-axis mounts to the carriage and carries torch height control (THC); set travel limits and calibrate probe offset so the torch references material reliably without diving or stalling.

Couple stepper motors through belt reduction drive assemblies to increase torque and resolution. Align pulleys, set belt tension, and verify steps-per-millimeter in firmware.

Bench test motors, limit switches, and THC I/O before final install. Configure the plasma trigger for auto-start from the control box, isolating signals to avoid EMI-induced misfires.

- Aluminum gantry floating over the slat bed, gliding true

- Z-slide probing, torch kissing the sheet at pierce

- Belts humming, pulleys synchronized under load

- Control box LEDs sequencing to a clean auto-start

Fume Management: Downdraft Vs Water Table

Even before you cut your first part, decide how you’ll capture smoke and sparks: a downdraft plenum or a water table.

A downdraft system uses fume extraction via suction points plumbed with 10-inch HVAC ductwork, pulling contaminants downward and out without cooling the workpiece. This preserves kerf geometry and avoids thermal shock to thin material.

Choose downdraft if you want maximum airflow efficiency and a cleaner shop. Correctly sized duct area, short runs, and balanced suction zones under the slats are critical. Place intakes near typical cut paths and segment the plenum to maintain velocity as debris accumulates. With proper capture, you reduce lingering smoke, fine particulates, and fire hazards from smoldering dust.

Choose downdraft for cleaner air: sized ducts, short runs, balanced zones, segmented plenums, safer cuts.

A water table excels at quenching sparks and trapping slag, but it adds corrosion potential, water treatment, and thermal distortion of small parts.

If you prefer flexibility, design a removable cutting surface so you can retrofit a water pan later without reworking the frame.

Calibration, Test Cuts, and Example Projects

Two checks define your first run: mechanical calibration and controlled test cuts.

Start with calibration techniques that square the gantry. Measure diagonals, verify X–Y orthogonality at 90 degrees, and adjust rail alignment until backlash and racking disappear. Traverse the full table to confirm even motion, then validate limit microswitch actuation at each corner and along both axes.

Update steps-per-unit and acceleration in the control system so commanded moves match measured travel.

Follow your controller’s manual for a standardized program—this reinforces test cut importance and verifies pierce height, cut height, and feed rates.

Inspect edges: you want minimal dross, perpendicular kerf walls, and no step-loss marks. The first clean cuts confirm readiness; inconsistent results cue further adjustment.

- A machinist square kissing both axes, light shining through any misalignment

- A dial indicator crawling the rail, tenths reading flatness

- Blue arc, steady kerf, sparks trailing 15–20 degrees

- A bracket nested, cut in minutes, fit perfect on first pass

Frequently Asked Questions

How Noisy Is a CNC Plasma Cutter in a Residential Garage?

Expect high sound levels—typically 85–100 dB during cutting, with piercing bursts when piercing metal. You’ll need noise reduction: enclosure, acoustic panels, ear protection, compressor isolation, water table, and lower amperage settings. Neighbors may still notice during operation.

What Safety Gear Is Essential Beyond Eye and Hearing Protection?

You need fire resistant clothing, respiratory protection (P100 or supplied air), leather gloves, steel-toe boots, welding cap, face shield, flameproof apron, cut-resistant sleeves, and a Class ABC extinguisher. Guarantee fume extraction, proper grounding, and cable management to mitigate hazards.

Can I Run the Setup on Standard Household Electrical Circuits?

Yes, but verify power requirements. Many 50–60 A plasma units draw 30–40 A at 240 V—over 3× a 15 A circuit’s capacity. You’ll likely need circuit modifications: dedicated 240 V, correct breaker sizing, proper wire gauge.

How Do I Handle Electromagnetic Interference With Nearby Electronics?

Mitigate EMI by implementing star-grounding techniques, bonding machine frames, and using shielded cables with proper terminations. Enclose controllers in metal housings, route signal and power separately, add ferrite chokes, use line filters, and maintain distance from sensitive electronics and antennas.

What Insurance or Permitting Considerations Apply for Home-Built Machines?

You’ll need liability coverage and permits per local regulations. Disclose homemade status, document safety controls, and photograph installations. Confirm homeowner policy exclusions, consider umbrella limits, and obtain shop endorsements. Verify electrical inspections, zoning, fire code compliance, and operator training attestations.

Conclusion

You’ve mapped your 4×8 envelope, chosen a CNC-ready plasma, compressor, and software, and built a rigid frame with a removable slat bed. Dial in motion control for the gantry and Z, then manage fumes via downdraft or water—safety first. Calibrate steps-per, torch height, and kerf; validate with test cuts. Costs vary, so lock a baseline budget early. Now you’re ready to cut steel like a scalpel through silk—precise, repeatable, and production-ready.