Coincidentally, your Powermax 1650’s cut quality hinges on the very consumables most shops under-manage. You’ll need the right electrodes, nozzles, shields, and retaining caps matched to amperage, plus Duramax HRT/MRT retrofit options for legacy performance gains. Starter kits, bulk packs, and replacement torch assemblies reduce downtime and standardize parts. We’ll map compatibility, duty cycles, and part numbers—and flag maintenance intervals—so you can forecast cost per cut and spot the upgrade that pays back fastest…

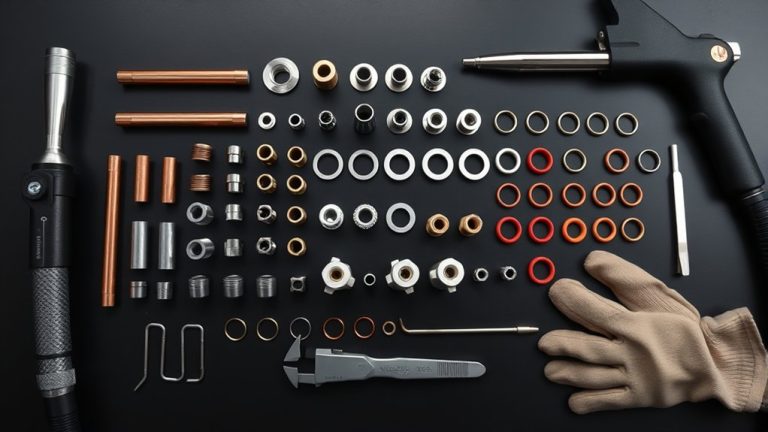

Essential Torch Components for Powermax1650

Precision starts at the torch. For the Powermax1650, you’ll anchor performance with the Duramax HRT Hand Torch Assembly—25 ft leads at $640.30 or 50 ft at $786.69—specified to deliver stable arc transfer and ergonomic control.

Pair it with correctly rated consumables: electrodes (~$35.64 per 5-pack), 100 Amp Shielded Nozzles at $10.09, and the Ohmic Retaining Cap (40–80 A) at $58.99 to maintain voltage sensing accuracy and cut quality.

Use the Hypertherm 128644 Torch Handle Replacement Kit at $84.00 to restore grip integrity and cable strain relief when wear is evident.

Apply torch assembly maintenance on a fixed interval: inspect threads, O-rings, and seating faces; verify nozzle-to-electrode standoff; and confirm shield integrity to prevent double-arcing.

Component replacement tips: replace electrodes when pit depth approaches manufacturer limit; change nozzles if orifice is ovalized or edge-chipped; replace retaining caps with any cracking or ohmic failure.

Always match amperage ratings and part compatibility to sustain duty cycle and cut repeatability.

Consumable Kits and Bulk Pack Options

With torch maintenance intervals set, you can standardize replenishment using Hypertherm’s kits and bulk packs to control cost-per-cut and minimize downtime.

Starter kits align parts by application, so you deploy matched nozzles, electrodes, and caps without piecemeal ordering. For example, the Consumables Starter Kit at $227.00 provides a baseline set that supports repeatable setup and traceable usage.

Bulk savings come from high-volume packs with predictable burn rates. A Duramax Gouging Nozzle 45–85 A pack of 25 at $240.00 lowers unit cost and reduces changeout interruptions.

You can pair bulk nozzles with the 220037 100 A machine electrode at $13.39 to keep current density and arc stability within spec across long runs. The 220061 Ohmic Retaining Cap (40–80 A) at $58.99 maintains reliable ohmic contact for accurate height control.

Replacement kits, such as the Torch Handle Replacement Kit at $84.00, restore ergonomics and safety. These choices deliver measurable consumable advantages and inventory discipline.

Duramax Retrofit Torches for Legacy Systems

You can retrofit your Powermax 1650 with Duramax HRT (25 ft, $690) or MRT (mechanized, $1,110) torches to gain compatibility with newer consumables and improved cut quality.

Expect standards-aligned integration across Hypertherm systems, maintaining duty cycle, arc stability, and consumable life while preserving your existing power supply.

Plan installation by confirming lead length, connector interface, and mechanized mounting, then budget for torch cost plus any application-specific accessories.

Compatibility and Benefits

Although your Powermax1650 may be a legacy platform, Duramax Retrofit Torches preserve full compatibility while delivering measurable gains in performance and uptime.

With torch upgrades engineered for legacy compatibility, you keep your existing power supply and interface while adopting current torch technology and consumables. You can choose the Duramax HRT handheld or the MRT mechanized variant to match operational requirements.

You’ll maintain system continuity while improving cut quality, reliability, and duty-cycle efficiency. The retrofit design supports 25- or 50-foot leads, enabling optimized cable management for benches, gantries, and field work.

Standardized consumable geometry streamlines inventory and reduces changeover time. Handheld and mechanized options—priced at $690.00 (HRT) and $1,110.00 (MRT)—give you a predictable pathway to modern performance without replacing the Powermax1650.

In short, you extend asset life and boost throughput.

Installation and Cost

Even on legacy Powermax1650 platforms, installing a Duramax retrofit torch is a straightforward, standards-driven swap that uses existing connectors and maintains full system I/O. Follow these installation tips: verify torch lead integrity, lock out power, match pinout to OEM schematic, and perform a test pierce to validate arc transfer. You’ll cut downtime and stabilize cut quality immediately.

Use this cost comparison to plan upgrades and justify ROI against reduced consumable waste and setup time.

| Item | Value |

|---|---|

| HRT Retrofit Torch (hand) | $690.00 |

| MRT Retrofit Torch (mechanized) | $1,110.00 |

| Install Time (typical) | 20–40 minutes |

| Expected Quality Gain | Higher edge fidelity, fewer dross passes |

| Lifecycle Benefit | Extends legacy system service life |

Both torches preserve compatibility while delivering modern performance.

Nozzles, Electrodes, Shields, and Caps by Amperage

You should match consumables to load: select amperage-specific nozzles (e.g., 80 A shielded at $10.09 or 100 A shielded at $10.09) to maintain cut quality and arc stability.

Pair electrodes by range, such as the Hypertherm 220037 for 100 A in a 5-pack at $35.64, to meet duty-cycle and wear-rate expectations.

Align shields and caps to the setpoint—40–80 A machine shield at $20.24 with the 40–80 A retaining cap at $39.82 or ohmic cap at $58.99, and 100 A hand shield at $21.26 with the 100 A retaining cap at $51.79—to guarantee system compatibility and safety.

Amperage-Specific Nozzle Choices

Amperage dictates consumable selection on the Powermax1650, with distinct parts specified for 40–80 A and 100 A cutting. To optimize nozzle performance, match amperage selection to the rated consumable set.

For 40–80 A work, pair the 80 A Hypertherm 120927 nozzle ($10.09) with the 120930 machine cutting shield ($20.24) and 220061 retaining cap ($58.99). For 100 A cutting, use the 220011 100 A shielded nozzle ($10.09) with the 220048 retaining cap ($51.79) and compatible 100 A components.

This alignment stabilizes arc density, maintains kerf quality, and prolongs part life.

- Choose 80 A nozzles for thin-to-medium plate; 100 A for heavy sections.

- Verify nozzle orifice size matches current.

- Replace nozzles at first sign of ovality.

- Track cost per cut, not unit price.

- Keep shields/caps matched to nozzle rating.

Electrode Options by Range

Two amperage bands define the Powermax1650’s consumable sets, and each must be matched to its rated components to maintain arc stability, kerf quality, and part life.

For electrode options by range, you’ll primarily spec the 100-amp class: the Hypertherm 220037 electrode (five-pack, $35.64). Pair it with the 100-amp 220011 nozzle ($10.09) to hold current density and constriction within design limits.

In an electrode performance analysis, this 100-amp pairing minimizes double-arcing and preserves cut angularity at rated duty.

For lower-current operations using 80-amp setups, retain correct component ratings via appropriate caps (e.g., 120928), while maintaining electrode-to-nozzle alignment and standoff.

In an electrode lifespan comparison, consistent 100-amp matching typically yields predictable wear patterns and cost-per-cut, aided by Hypertherm’s ongoing OEM supply continuity.

Shields and Caps Pairing

Building on the 100 A and 80 A electrode/nozzle matches, correct shields and retaining caps lock in arc constriction, gas flow, and standoff control by amperage.

Pair the 220037 electrode with the 220011 100 A nozzle and the matching 100 A shield to stabilize kerf geometry and extend consumable life. For 80 A, run the 120927 nozzle with the 80 A shield and the specified retaining cap for consistent edge quality.

The 40–80 A retaining cap (120928) supports versatility when matched to the 120929 hand cutting shield and appropriate nozzles. Select shield types and cap materials to match duty cycle and part geometry, minimizing turbulence and double arcing.

- 100 A: 220011 nozzle + 100 A shield

- 100 A: 220037 electrode alignment

- 80 A: 120927 nozzle + 80 A shield/cap

- 40–80 A: 120928 cap + 120929 shield

- Verify amperage labels before mixing components

Cables, Leads, and Filtration Accessories

Dial in reliable connections and clean air with Powermax 1650 cables, leads, and filtration accessories that meet Hypertherm’s performance standards.

Apply cable maintenance tips to preserve conductivity: inspect lugs, clean contact surfaces, verify strain reliefs, and maintain bend radii. The Hypertherm 123654 Extended Work Cable with Clamp (20 ft, $164.03) increases mobility without excessive resistance, while the 123655 (50 ft, $310.42) extends reach for larger fixtures—select length based on layout to minimize voltage drop and trip hazards.

Preserve conductivity: inspect lugs, clean contacts, protect strain reliefs, maintain bends. Choose 20 ft or 50 ft to reduce drop and hazards.

Maintain torch integrity with the Hypertherm 128755 T100 25 ft Torch Lead Replacement Kit ($815.96). Replace aging leads to stabilize arc initiation, maintain current capacity, and prevent intermittent faults that degrade cut quality.

Prioritize dry, clean air with filtration system upgrades. The Powermax Air Filtration Kit HYP128647 ($295.00) reduces particulates and moisture that erode consumables.

Schedule differential-pressure or hour-based service and install the Hypertherm Replacement Filter Element HYP228695 ($55.50) to keep flow within spec and protect internal components.

Compatibility, Resources, and Technical Support

Although the Powermax1650 was last built in 2012, you can keep it production-ready with validated consumables, upgrade paths, and factory support. Hypertherm still manufactures critical consumables and repair parts, so you can standardize maintenance with predictable performance.

Leverage compatible torch assembly options like Duramax HRT and MRT, plus Duramax Hyamp and Retrofit documentation, to execute upgrades without guesswork. For consumable longevity, specify the CopperPlus electrode, engineered for the Powermax1650 to reduce erosive wear and stabilize arc starts.

- Access Hypertherm manuals for Duramax, Duramax Hyamp, and Retrofit torches to confirm correct assembly torque, O‑ring lubrication, and duty cycle limits.

- Use technical troubleshooting tips from Hypertherm support to diagnose double-arcing, blowback faults, and misfires.

- Validate part numbers against current engineering change notices to prevent cross‑series mix-ups.

- Implement CopperPlus electrodes for extended life; log pierce counts and cut length to quantify gains.

- Contact Hypertherm technical service for parameter baselines, compatibility checks, and failure-mode analysis.

Where to Buy and Pricing Snapshot

With validated consumables and upgrade paths in place, source parts through Hypertherm and authorized distributors to keep the Powermax1650 in spec. You’ll get verified fit, current lot codes, and warranty-aligned traceability—critical since production ended in 2012.

Evaluate purchase options by matching part numbers and amperage ranges to your cut or gouge profiles.

Use this pricing snapshot as a baseline for budgeting and inventory control:

- Hypertherm 128644 Torch Handle Replacement Kit runs $84.00.

- The Hypertherm 228788 Duramax HRT Hand Torch Assembly with 25 ft leads lists at $640.30.

- Core consumables include the Powermax1650-specific 220037 Electrode, five-pack at $35.64.

- For high-throughput work, bulk buys improve cost per cut: Duramax Gouging Nozzle 45–85 A, 25-pack at $240.00.

Track pricing trends quarterly—authorized channels typically adjust with copper and tungsten markets.

Validate stock freshness, packaging authenticity, and distributor status. Standardize reorder intervals and minimums to stabilize cost, reduce downtime, and maintain consistent cut quality.

Frequently Asked Questions

How Can I Diagnose Premature Consumable Wear on the Powermax1650?

Inspect arc-on time logs, electrode pit depth, and nozzle orifice growth to diagnose premature wear. Apply diagnostic techniques: verify gas pressure, coolant flow, arc voltage, standoff, pierce height, cut speed, duty cycle, consumable lot traceability, and torch alignment.

What Storage Conditions Extend Shelf Life of Consumables?

Store consumables at 18–22°C ideal temperature with 35–55% humidity control; this extends shelf life up to 30%. You’ll keep packaging sealed, purge with desiccant, avoid UV/ozone, prevent vibration, and segregate copper from steel to minimize galvanic corrosion.

Are There Safe Practices for Cutting Painted or Galvanized Steel?

Yes. You wear a fit-tested respirator, use local exhaust per ACGIH/OSHA, and monitor zinc/lead fume hazards. Implement hot-work permits, remove coatings mechanically, confirm fire watch, maintain grounding, manage sparks, and verify ventilation meets calculated capture velocities for cutting safety.

How Do I Dispose of Used Electrodes and Nozzles Responsibly?

You segregate metal by type, check local recycling options, and route copper/brass/tungsten to scrap streams. You avoid landfill, document chain-of-custody, and follow waste management regulations (RCRA/EEE). You bag residues, label containers, and verify recycler certifications and recovery rates.

What Maintenance Schedule Reduces Torch Downtime Between Shifts?

Implement daily torch care: inspect consumables, clean threads, check O-rings, verify cooling, and log arc-on hours. Weekly, calibrate gas pressure and leak-test. Replace at wear limits. Standardize checklists per ISO 9001 to maximize shift efficiency and minimize downtime.

Conclusion

You keep cut quality tight by treating consumables like calibrated gauges—replace on schedule, not when failure forces you. One shop cut a 400-part run; swapping electrodes at 40% wear (per resistance checks) cut dross rework by 32%. Use Duramax HRT/MRT retrofits to standardize on newer nozzles and caps, and stock starter kits plus bulk packs for uptime. Document amperage-to-nozzle mappings, inspect retaining caps every shift, and log arc starts—data beats guesswork, every time.