Like tuning a race car, your Powermax85 runs best when the right consumables are in place and checked on schedule. You’ll match CopperPlus electrodes (220932) with HyAccess nozzles (220938), pair ohmic retaining caps (220940) and deflectors (220954), and consider the Essential Handheld 85 A Kit at $232.79 for a streamlined setup. Monthly torch and power‑supply inspections prevent premature wear and protect cut quality—but the real gains come from how you stage your spares next.

Powermax85 Consumables Overview and Compatibility

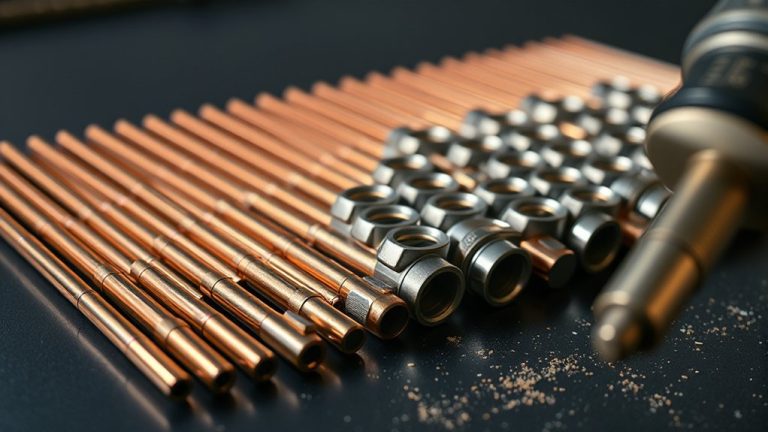

Start with the essentials: Powermax85 consumables are engineered for 85 A handheld cutting and include CopperPlus electrodes, compatible nozzles (Duramax HyAccess, FineCut), and Ohmic retaining caps to stabilize arc start and cut quality.

You’ll match parts to your cutting techniques by prioritizing nozzle selection: use HyAccess for reach and visibility in tight joints, choose FineCut for thin material precision, and pair each with CopperPlus to extend electrode life.

Maintain performance by inspecting the retaining cap, nozzle orifice, and deflector at every shift; replace components showing pitting, ovality, or spatter adhesion.

Inspect retaining cap, nozzle orifice, and deflector each shift; replace parts with pitting, ovality, or spatter.

Keep the shield clean to preserve arc constriction and kerf consistency. Verify torch lead connections and cap seating to avoid misfires and double-arcing.

For consistent starts on coated or rusty plate, guarantee reliable Ohmic contact and replace worn caps promptly. Stock bulk CopperPlus electrodes to reduce cost per cut and downtime.

Align amperage, travel speed, and standoff with your chosen nozzle to protect consumables and cut quality.

Essential Handheld 85 A Kit Contents and Pricing

For handheld cutting at 85 A, you’ll use the Essential Handheld 85 A Kit, which includes CopperPlus electrodes, nozzles, and retaining caps matched to the Powermax85.

The current kit price is $232.79, and it’s optimized for reliable cut quality and consumable life with the system’s advanced features.

For maintenance planning, consider the 25-pack of CopperPlus electrodes at $298.77 to reduce per-part cost on high-use schedules.

Kit Components Overview

Built for dependable handheld cutting, the Essential Handheld 85 A Kit for the Powermax85 packages the core consumables you need: CopperPlus electrodes, precision nozzles, retaining caps, and a deflector for unshielded cuts.

You get a matched set optimized for 85 A handheld work, improving cut quality, arc stability, and consumable life. Users report consistent ignition and slower wear when switching to CopperPlus, reinforcing clear kit benefits and reliable user experiences.

Use the CopperPlus electrodes for extended life under frequent starts, pair them with the 85 A nozzles for tight kerf control, and inspect nozzle orifices for ovaling to maintain accuracy.

Keep the retaining cap threads clean to prevent overheating. Install the deflector only for unshielded cuts. Replace parts as a set when cut faces roughen.

Current Kit Pricing

At $232.79, the Essential Powermax85 Handheld Consumable Kit delivers a matched 85 A set for dependable handheld cutting: CopperPlus electrodes (optimized for 12 mm/1/2 in and under), 85 A nozzles, an ohmic retaining cap, and a deflector for unshielded cuts.

Use this kit when you need predictable cut quality without chasing parts individually. It aligns with current pricing trends for name-brand consumables and provides a clear value comparison against piecemeal purchases.

For high-volume users, evaluate bulk CopperPlus electrodes: a 25-pack at $298.77 can lower per-electrode costs and reduce downtime from frequent reorders. Balance kit convenience with bulk replenishment—run the kit to standardize your setup, then stock electrodes in bulk to maintain tip life and torch readiness.

Verify inventory and rotate consumables to prevent premature wear.

Part Numbers for Nozzles, Electrodes, Shields, and Caps

Consumables tracking starts with correct part numbers to avoid downtime and miscuts. For stable electrode performance, stock the CopperPlus electrode 220932, optimized for cutting up to 12 mm and consistent arc starts.

Match nozzle types to your amperage and access needs: Duramax HyAccess nozzles 220938 serve 45–65 A cutting where reach and visibility matter on intricate features.

Ensure reliable electrical contact with the ohmic retaining cap 220940; replace it at the first signs of thread wear, plating loss, or intermittent ohmic sensing.

For unshielded cutting, use deflectors 220954 to direct plasma flow and protect the torch front end; inspect for heat distortion and spatter buildup.

When gouging, fit the Powermax 85–specific gouging shields 220855 to maintain correct standoff and gas flow.

Log hours-on-part, cut quality, and arc voltage stability to schedule replacements proactively. Always replace consumables as a matched set when edge angularity, arc chatter, or dross increases.

Cutting and Gouging Accessories for Duramax and HyAccess Torches

You’ll choose from the Duramax HyAccess nozzle lineup to match 45–65 A cutting or precision FineCut tasks, and use FlushCut assemblies when running 65–105 A systems.

Verify gouging shield compatibility with Powermax65/85/105 to protect the torch and maintain stable metal removal.

Inspect swirl rings during changes to sustain gas flow control and consistent cut quality.

Hyaccess Nozzles Lineup

Sometimes the tightest joints demand a different nozzle. The HyAccess nozzles give you clear HyAccess advantages: slim profiles, better line‑of‑sight, and controlled access for tight‑space nozzle applications.

Use them for cutting and gouging from 45–105 A on Duramax and HyAccess torches, matched to Powermax65, Powermax85, and Powermax105. Select amperage to fit material thickness; don’t exceed rated current.

For precision work, FineCut nozzles deliver narrow kerf and clean edges on intricate profiles—inspect orifice roundness and replace at the first sign of taper or dross increase.

For material removal near surfaces, the FlushCut nozzle/shield assembly (65–105 A) lets you sever attachments nearly level with the base metal.

Maintain performance by keeping nozzles clean, checking seating surfaces, monitoring arc start consistency, and replacing worn consumables as a set.

Gouging Shields Compatibility

When tight‑access nozzles and FineCut tips aren’t enough, pair the correct gouging shield with your Duramax or HyAccess torch to control arc exposure and spatter during metal removal. Gouging shields for Powermax65/85/105 deliver performance enhancement in gouging applications by stabilizing standoff and protecting the nozzle. Use HyAccess nozzles for 45–65 A precision work; step up to FlushCut nozzle/shield assemblies for 65–105 A versatility. FineCut nozzles can be combined with gouging shields for delicate material removal. Maintain swirl rings in good condition to sustain consistent flow and efficiency.

| Selection | Guidance |

|---|---|

| Powermax model | 65/85/105 compatible |

| Amperage 45–65 A | Choose HyAccess nozzle + gouging shield |

| Amperage 65–105 A | Use FlushCut nozzle/shield assembly |

| Precision need | Add FineCut nozzle under shield |

| Maintenance | Inspect swirl ring, shield orifices, replace on wear |

Maintenance Schedules, Safety Procedures, and Tools

Although the Powermax 85 is built for durability, its reliability depends on a disciplined maintenance schedule and strict safety controls.

Set maintenance frequency as follows: perform a monthly inspection of the inverter and torch system; verify labels are legible, replace any that are damaged, and check the torch body for cracks.

Inspect the power cord and plug for cuts, exposed conductors, or heat damage; replace defective parts immediately.

Every six months, clean the power supply interior with dry compressed air or a vacuum to remove conductive dust.

Follow safety precautions without exception. De-energize the unit, unplug it, and apply lockout-tagout before any service.

Only qualified technicians should remove the power supply cover or access internal circuitry. Verify zero energy with a meter prior to work.

Recommended tools: insulated screwdrivers, torque wrench (per OEM specs), non-contact voltage tester, digital multimeter, flashlight, mirror, soft brush, ESD wrist strap, dry compressed air, HEPA vacuum, label kit, and OEM torch O-ring lubricant.

Where to Buy, Availability, and Authorized Partner Contacts

For straightforward sourcing, buy Powermax 85 consumables from authorized Hypertherm distributors or the Hypermax Online store to confirm OEM fit and performance.

These buying options protect torch life, maintain cut quality, and assure part-number fidelity. If you need a ready-to-run set, the Essential Powermax85 Handheld Consumable Kit is $232.79 and covers routine cutting tasks.

For higher duty cycles, choose bulk Copper Plus electrodes—$298.77 for 25—to extend electrode life on steel and stainless.

Confirm regional availability before ordering. Stock and lead times vary, so provide your city, state, or country to match you with the correct partner and shipping lane.

For pricing, stock checks, or to locate an authorized partner, call Hypermax Online at 410-687-8400, 07:30–05:00 E.S.T. They’ll verify OEM part numbers, bundle kits for your amperage, and align nozzle/electrode counts with your maintenance schedule.

Avoid non-OEM sources; mismatched tolerances accelerate wear and compromise cut consistency.

Frequently Asked Questions

How Do I Store Consumables to Prevent Corrosion or Contamination?

Store consumables in sealed, labeled containers with desiccant; keep them dry, clean, and temperature-stable. Use anti-corrosion sleeves, avoid skin oils, and rotate stock. Apply storage techniques like vacuum-bagging for corrosion prevention. Inspect before use; discard compromised parts.

What Signs Indicate Counterfeit Powermax 85 Consumables?

You spot counterfeit indicators when packaging screams “generic luxury,” serials don’t verify, machining looks rough, plating flakes, tolerances don’t fit, and lifespan nosedives. Validate consumable authenticity via OEM lot codes, weight checks, dimensional inspection, cut quality benchmarking, and vendor traceability.

Can I Track Consumable Life With Machine Usage Logs or Apps?

Yes. You can correlate consumable life with machine usage logs and dedicated apps. Use runtime counters, pierce counts, and arc-on time as tracking methods. Calibrate thresholds, log replacements, and review trend data to schedule maintenance and prevent premature failures.

How Do Ambient Temperature and Humidity Affect Consumable Longevity?

Ambient temperature and humidity directly affect consumable longevity. Temperature effects: cold thickens air, reduces cut quality; heat accelerates oxidation. Humidity impacts: moisture causes arc instability, pitting, double-arcing. You’ll extend life by drying air, stabilizing temperature, and enforcing post-run cooldowns.

What Warranty Coverage Applies Specifically to Consumables?

Like a fuse, coverage is limited: you typically get no warranty on wear items. Review warranty specifics by consumable types; defects-in-materials may apply briefly. Document installation, follow maintenance schedules, and track duty cycles to support any claim.

Conclusion

Treat your Powermax85 like a precision vessel: you’re the captain, the consumables your rigging. Stock the Essential Handheld 85 A kit, verify part numbers—220932 electrodes, 220938 nozzles, 220940 ohmic caps, 220954 deflectors—and match them to Duramax or HyAccess torches. Schedule monthly inspections of torch and power supply, watch wear patterns, and replace before quality drifts. Follow safety checks, keep tools clean, and source from authorized partners. Steady maintenance keeps your cuts true and your voyage efficient.