You don’t need to requalify cut charts—the Powermax 88 runs standard Hypertherm consumables and preserves your established parameters. You’ll spec the 220842 electrode, unshielded cutting nozzles, and compatible shields for consistent arc starts and kerf control. CopperPlus options extend life on higher duty cycles, while Duramax HyAccess expands reach in tight geometries. FineCut and FlushCut alternatives refine edge quality and removal tasks. Starter kits, bulk packs, and SmartSYNC adapters round out a cost-efficient, upgrade-ready path—if you choose wisely.

Compatibility Across Powermax Systems

Although legacy torch platforms vary, the Powermax 88 maintains broad cross-system compatibility with Hypertherm consumables, including electrodes, nozzles, and starter kits engineered to spec for cutting and gouging.

You get validated Powermax compatibility across torch families, so you can deploy existing inventories without requalifying cut parameters. The system’s interface tolerances and gas-flow profiles align with Hypertherm standards, preserving kerf quality, arc stability, and consumable life across a range of amperages and materials.

Leverage SmartSYNC integration for streamlined setup. With the single-piece cartridge, you reduce part count, eliminate mis-stacks, and shorten changeover.

Leverage SmartSYNC for faster setup—single-piece cartridges cut parts, prevent mis-stacks, and speed changeovers.

If you’re running older Powermax platforms, System upgrades are straightforward: add the torch adapter to enable SmartSYNC cartridges without a full unit replacement. That retrofit maintains electrical characteristics and torch ergonomics while improving process repeatability and error-proofing.

Across varied metal thicknesses, the Powermax 88’s compatibility matrix supports consistent cut speeds, pierce reliability, and duty-cycle utilization, ensuring predictable performance in fabrication, maintenance, and light production environments.

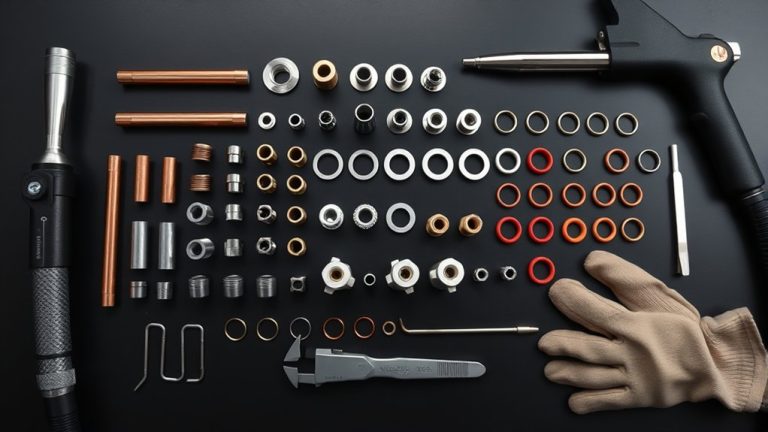

Essential Consumable Parts for Powermax 88

Consumables define the Powermax 88’s cut quality and uptime, with a core set centered on electrodes, nozzles, and retaining caps engineered for plasma arc stability under high thermal load.

For baseline configuration, prioritize the Hypertherm Electrode #220842 and the Unshielded Cutting Nozzle; both are spec’d for consistent arc initiation, low blowout risk, and tight kerf control across mixed thickness ranges.

You’ll maximize productivity by standardizing part numbers and implementing disciplined electrode maintenance and scheduled nozzle replacement tied to arc-start counts or visual wear indicators.

These components are built for high duty cycles and intense heat exposure, maintaining cut speed and edge angularity when amperage and standoff are correctly tuned.

Keep retaining caps within tolerance to preserve gas swirl integrity and nozzle concentricity.

Stock consumables in bulk packs where available to reduce cost per pierce and mitigate downtime.

With readily available replacements, you can sustain throughput and keep the torch performance within spec.

CopperPlus Electrodes: When and Why to Use Them

When should you swap to CopperPlus electrodes on a Powermax 88? Do it when you’re cutting mild or stainless up to 12 mm (1/2 in) and you want tighter heat control, longer electrode lifespan, and fewer changeouts.

CopperPlus advantages come from a copper-rich formulation that boosts thermal conductivity and heat resistance, stabilizing the arc and reducing pit formation and mushrooming at the insert.

1) Use cases: frequent pierces on plate ≤12 mm, mixed-duty production, and shops targeting lower cost-per-cut via extended wear intervals.

2) Performance specs: improved heat transfer reduces tip recession, maintains arc density, and sustains kerf consistency over longer runs, yielding longer intervals between replacements and minimizing downtime.

3) Integration: they’re drop-in compatible with the Powermax 88, requiring no parameter tweaks—just verify amperage is within the torch’s standard cut range for the material thickness.

Choose CopperPlus when you want reliable cut quality in challenging thermal loads and predictable consumable life.

Duramax HyAccess Nozzles and Extended Reach Options

Because tight access often dictates torch choice, Duramax HyAccess nozzles give you extended reach for precise cutting and gouging in confined geometries at 45–65 A. You’ll gain accessibility benefits via a slim, elongated nozzle profile that clears obstructions and maintains standoff where standard fronts can’t fit. The result is better line-of-sight, steadier arc transfer, and higher cutting efficiency in pockets, webs, and recessed features.

These HyAccess nozzles are engineered for Powermax platforms and maintain amperage-specific orifice geometry to stabilize the plasma column under extended-reach conditions. Expect cleaner kerfs, reduced dross, and consistent edge angularity when paired with correct gas pressure, consumable stack-up, and work-lead integrity.

Cross-compatibility across multiple Powermax models streamlines inventory and setup when you alternate between benches, fixtures, and field work.

Stock HyAccess consumable kits to minimize downtime: keep nozzles, shields, and matching electrodes bundled for quick turnarounds. Use them whenever torch approach is limited but cut quality and throughput must remain specification-compliant.

FineCut and FlushCut Alternatives for Precision and Specialty Cuts

Although both are specialty fronts, FineCut and FlushCut nozzles give your Powermax 88 distinct advantages for precision and close-proximity work.

FineCut targets precision cutting on thin stock—typically ≤6 mm (1/4 inch)—tightening arc column, narrowing kerf, and sharpening feature fidelity.

FlushCut aligns the arc nearly parallel to the plate, enabling close proximity cutting that removes protrusions while minimizing kerf on thicker sections.

Both options drop into the Powermax 88 for fast changeovers across specialty applications.

1) Choose FineCut for intricate profiles, small hole accuracy, and reduced heat-affected zone on sheet and light plate. Expect cleaner edges and less post-process deburr.

2) Select FlushCut to skim welds, tabs, and attachments flush to the parent metal, protecting base material and preserving geometry on heavy plate.

3) Use alternatives strategically to improve cut quality, mitigate taper, and decrease secondary finishing.

Compatibility with the Powermax 88 guarantees versatile deployment in tight spaces and detailed fabrication.

Starter Kits, Bulk Packs, and Cost-Saving Bundles

Even before you strike an arc, starter kits for the Powermax 88 standardize your setup with matched nozzles, shields, swirl rings, and CopperPlus electrodes to hit spec out of the box. You lock in consumable selection that aligns with factory amperage windows and gas dynamics, reducing tolerance stack-up and ensuring performance optimization from the first pierce. Kits cover cutting and gouging profiles, so you minimize changeovers and keep uptime high.

Bulk packs drive cost per cut down. CopperPlus electrodes in 25-piece sleeves provide predictable wear patterns and fewer stops for reloads—ideal for shift-based throughput targets. Cost-saving bundles pair high-burn items (nozzles, electrodes) for a lower aggregate price versus piecemeal purchasing, with recurring discounts to help you stock strategically.

| Package Type | Contents Focus | Primary Benefit |

|---|---|---|

| Starter Kit | Balanced mix incl. swirl rings | Spec-compliant setup |

| Bulk Pack | 25 CopperPlus electrodes | Lowest unit cost |

| Bundle | Nozzles + electrodes | Reduced total spend |

SmartSYNC Cartridge Upgrades and Torch Adapters

You can upgrade your Powermax 88 to SmartSYNC cartridges for single-piece consumables, auto process setpoints, and color-coded ID, cutting setup time while extending life up to 5X.

With the SmartSYNC torch adapter, you’ll run these cartridges on existing handheld or mechanized torches without rewiring or control changes.

This adapter-enabled compatibility expands application coverage for cutting and gouging while standardizing consumable management.

Smartsync Cartridge Benefits

While legacy five-piece stacks demand careful assembly and tuning, SmartSYNC cartridges deliver a single-piece, color-coded consumable that auto-configures amperage and mode at the torch, cutting setup time and misfire risk.

You gain SmartSYNC advantages with fewer touchpoints, tighter process control, and measurable efficiency improvements across shift operations.

1) Auto-setup and control: The cartridge communicates type and rating to the system, locking in amperage and process mode to spec, reducing parameter drift, and stabilizing arc starts for consistent kerf and cut quality.

2) Visual management: Color-coding accelerates identification by process (drag, mechanized, gouging), tightening inventory control and minimizing changeover errors under production cadence.

3) Predictive maintenance: End-of-life detection flags replacement intervals before degradation impacts arc density, preventing unplanned downtime and maintaining repeatable edge geometry and consumable cost per foot.

Torch Adapter Compatibility

Building on SmartSYNC cartridge benefits, a torch adapter lets a Powermax 88 run the single-piece, color‑coded cartridges without replacing the power supply or torch. You gain backward-compatibility, automated process recognition, and simplified consumable logistics. Key torch adapter features include integrated SmartSYNC pinout mapping, secure mechanical latch-up, and signal integrity for automatic amperage and process parameter handshakes. Expect up to 5X consumable life, fewer setup errors, and faster changeovers.

Installation tips: verify firmware level, power down and discharge, align keyed couplers, torque to spec, and perform a test cut to validate arc transfer and consumable ID. Train operators on cartridge color codes and lockouts.

| Item | Spec | Result |

|---|---|---|

| Interface | Legacy torch to SmartSYNC | Full compatibility |

| Setup | Auto process settings | Consistent cuts |

| Lifecycle | Up to 5X | Lower cost/downtime |

Pricing, Availability, and Support Resources

You can source Powermax 88 consumables starting at $7.44, with pricing tiers by nozzle/orifice size, electrode metallurgy, and kit configuration.

For rapid fulfillment, buy in-stock SKUs (346+ parts) and essential starter kits through Welders Supply Company and authorized Hypertherm distributors.

For compatibility checks and order support, contact Welders Supply at 1.800.236.8825.

Current Pricing Ranges

Pricing spans entry-level single-piece consumables to bundled kits, giving clear cost control by application.

You can benchmark current pricing by matching duty cycle, amperage, and expected burn rate to specific consumable options. Entry points start around $7.44 for basic parts, with individual electrodes and nozzles commonly landing between $9.08 and mid-tier multi-packs.

Bulk packages scale up to $298.77, optimizing cost per pierce for high-volume shops. Essential handheld kits price around $232.79, consolidating the core stack for standardized torch setups.

1) Single components: electrodes, nozzles, and shields priced from $7.44 to $9.08+, with bulk tiers improving unit economics up to $298.77.

2) Kits: handheld essentials near $232.79 for predictable replenishment and minimized downtime.

3) Compatibility: Hypertherm-specified SKUs guarantee fitment and cut quality; for support, contact Hypermax Online at 410-687-8400.

Where to Buy

Looking to source Powermax 88 consumables with predictable lead times and verified SKUs?

Prioritize retailer options that publish part numbers, stock status, and cut-process compatibility. Welders Supply Company maintains inventory depth for Powermax 88 and related kits, reducing downtime and backorder risk.

Expect entry pricing from $7.44 for single nozzles/electrodes, with cost deltas by amperage rating and shield style.

For bundled value, target bulk packs and starter kits—e.g., the essential Powermax85 Handheld Consumable Kit at $232.79—for lower per-piece cost and turnkey readiness.

Purchasing tips:

- Validate SKU-to-torch match (handheld vs. mechanized) and gas selection.

- Compare unit price versus kit economics at anticipated duty cycle.

- Confirm lead time and ship-from location.

- Use phone support for cross-reference and substitutions: 1.800.236.8825.

- Document reorder intervals to standardize replenishment.

Frequently Asked Questions

How Do I Store Consumables to Prevent Corrosion and Moisture Damage?

Store consumables in sealed, desiccant-equipped containers; maintain humidity control below 40% RH. Use anti-corrosion VCI bags, nitrogen-purged cabinets, and silica gel. Avoid temperature cycling, direct contact with steel, and fingerprints. Implement FIFO, periodic inspection, and torque-cap protective caps.

What Safety Gear Is Recommended When Changing Powermax 88 Consumables?

Of course, you’ll only need everything. Wear safety goggles, protective gloves, flame-resistant sleeves, antistatic ESD wrist strap, ANSI-rated face shield, hearing protection, steel-toe boots, and cotton workwear; lockout-tagout, purge gas lines, verify zero-energy state, and follow OEM torque specs.

How Do I Diagnose Misfires or Double-Arcing Caused by Worn Parts?

You diagnose misfires or double-arcing by inspecting nozzle orifice erosion, electrode pit depth, and swirl ring cracks. Verify gas flow/pressure, duty-cycle adherence, and lead integrity. Use diagnostic tools: multimeter, oscilloscope, gas flowmeter, micrometer, borescope, and firmware logs to isolate misfire causes.

Can I Recycle Used Electrodes and Nozzles, and Where?

Yes. You can recycle spent electrodes and nozzles via certified recycling centers or scrap-metal yards. Segregate copper, hafnium inserts, and mixed alloys. Follow electrode disposal regulations, SDS guidance, and local WEEE/RCRA requirements. Document weights, material grades, and transfer manifests.

What Maintenance Schedule Extends Torch and Consumable Lifespan?

Adopt a weekly maintenance frequency: inspect swirl ring, electrode/nozzle wear, check coolant flow, verify torch-to-work lead integrity, clean air filter/dryer, calibrate arc-start gap, torque consumable stack. Log amperage-to-tip size adherence. This regimen maximizes consumable lifespan and cut quality.

Conclusion

You’ve now got the playbook: run Powermax 88 with Hypertherm-compatible consumables, drop in 220842 electrodes and unshielded nozzles, and deploy CopperPlus when duty cycle spikes. Reach tight geometries with Duramax HyAccess, swap to FineCut or FlushCut for precision, and stock bulk kits to flatten cost-per-cut. With SmartSYNC cartridges and torch adapters, you future-proof workflows. Treat your consumables like a calibrated gauge—tight tolerances, predictable wear, repeatable parameters—so uptime, cut quality, and throughput stay in spec.