I’m going to make a little thing. That line is where this whole idea started for me: a quick, clever mod to turn an old saw blade into a versatile attachment for an angle grinder. If you love DIY, metalworking, and life hacks, this trick will change how you look at worn tools and scrap metal. It is simple, cost-effective, and surprisingly powerful.

Important safety note: Do not mount circular-saw (toothed) blades to an angle grinder. Use only grinder-rated accessories that match or exceed your grinder’s RPM and are specified by the tool manufacturer. The steps below have been updated to reflect safer, standards-aligned practice.

Materials and tools you need 🔧

These are the basic items I used to make the “little thing” — a safer, grinder-rated setup for controlled cutting and grinding.

- Angle grinder (any common 4.5 or 5 inch unit)

- Grinder-rated thin cut-off wheel or diamond/ceramic metal cut-off wheel — must be labeled for metal and for your grinder’s RPM

- Proper grinder flanges/lock nut — the ones supplied by the manufacturer (no homemade spacers/adapters)

- Files, grinders, and clamps for prepping and fitting

- Cutting oil and wire brush to clean rust and paint off the workpiece

- Safety gear: gloves, eye protection, hearing protection, and a face shield

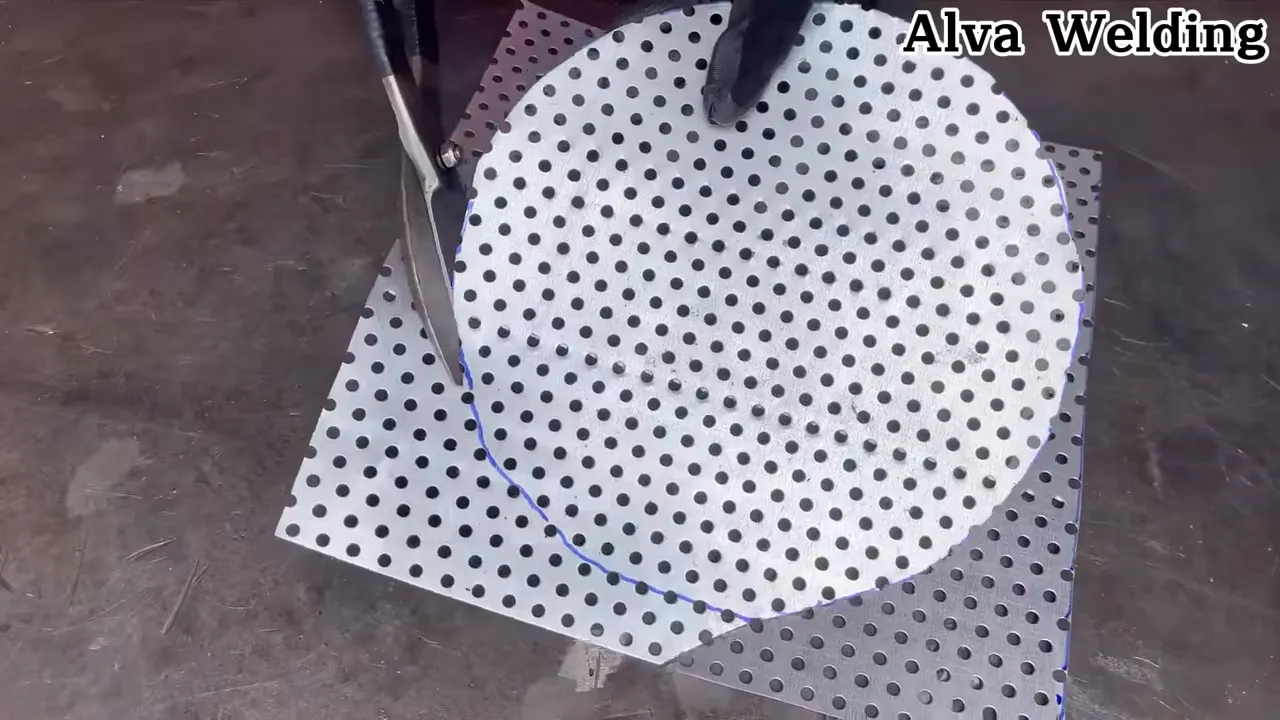

Step-by-step: how I built it 🛠️

I kept this build straightforward. The goal was to achieve a controllable, durable cutting or grinding tool using only grinder-approved accessories.

- Inspect and prepare the work. Clean the workpiece. Confirm your grinder’s guard is installed and correctly positioned.

- Verify accessory size and rating. Choose a wheel/disc that is the correct diameter and has a max RPM at or above your grinder’s no-load RPM.

- Mount with the supplied flanges. Do not use homemade adapters or spacers. Install the wheel per the grinder manual and tighten to spec.

- Never weld or modify accessories. Do not weld, press-fit, or otherwise alter blades/discs to make them fit. If it doesn’t fit as designed, don’t use it.

- Run-up test and balance check. Stand out of the wheel’s plane and run the grinder for 30–60 seconds. Stop immediately if there’s vibration.

- Use carefully. Make short, controlled passes. Let the wheel do the work; don’t force it.

“I’m going to make a little thing.”

That quote is my motto for small hacks that have big results. And yes, I even said “1 tbs vanille” a few times in the shop. It sounds weird, but it stuck in the footage — call it shop humor.

Safety first ⚠️

Repurposing blades and modifying rotating tools can be dangerous if you skip steps. These are the safety rules I follow every time.

- Always wear eye and face protection and hearing protection.

- Do not use circular-saw/toothed blades on an angle grinder. Use only accessories specifically rated for the tool and RPM.

- Balance the assembly before running at full speed. Vibration can throw the wheel or damage bearings. Stop immediately if vibration occurs.

- Secure the workpiece. Never hold small pieces by hand when cutting with a high-speed disc or blade.

- Inspect accessory condition and flange fit before each use. Do not use homemade adapters or welded assemblies.

Why this trick works and when to use it 💡

Standard abrasive wheels are great, but they wear down and can be expensive for some jobs. Grinder-rated thin cut-off wheels and diamond/ceramic metal wheels offer:

- Durability — high-quality wheels hold up well and are designed for grinder RPM.

- Cutting profile — thin kerf discs give precise control for trimming and small fabrication cuts.

- Cost efficiency — thin cut-off wheels are inexpensive and appropriate for the task.

Use this setup for light cutting, not heavy demolition. It excels at thin metal trimming, small fabrication cuts, and finishing where a thin wheel helps control the cut.

Troubleshooting and pro tips 🔍

- Wobble or vibration — stop immediately and recheck the wheel, flanges, and guard. Replace damaged wheels; never modify parts to fit.

- Poor cut quality — verify the wheel type matches the material (metal-rated, correct thickness) and is within its service life.

- Overheating — use short passes and let the material cool. Consider a few drops of cutting oil for thicker metals.

- Adapters — avoid homemade spacers or “permanent” modifications. Use only the manufacturer’s specified mounting hardware.

FAQ ❓

Can I use any saw blade on my angle grinder?

No. Do not use circular-saw/toothed blades on an angle grinder. Use only grinder-rated accessories that meet or exceed your grinder’s RPM and follow the manufacturer’s instructions and the current ANSI/UAMA B7.1 (current edition) guidance.

Is welding required to attach the adapter?

No. Do not weld or fabricate adapters to mount non-approved accessories. A grinder-rated wheel should be installed with the proper flanges and hardware supplied by the manufacturer.

Will this void grinder warranties?

Possibly. Modifying accessories or using nonstandard attachments can affect warranties and safety certifications. Always accept that you are altering the tool and take responsibility for safe assembly and operation — better yet, avoid non-approved attachments entirely.

What should I do if the accessory vibrates at speed?

Stop immediately. Re-inspect the assembly, check wheel condition, confirm proper flange orientation, and perform a run-up test. Do not use saw blades or modified adapters.

Why does the video repeat ‘1 tbs vanille’?

That phrase was a repeated line in the shop. It does not affect the build. Focus on the method and safety steps for the modification itself.

Final thoughts ✨

Turning an old saw blade into a useful angle grinder attachment is not recommended. Instead, choose grinder-rated accessories to save money and expand capability safely. For repurposing old saw blades, consider off-tool projects like scrapers, marking knives, or templates. Remember: plan, measure, balance, and protect yourself.