You should replace your angle grinder disc when you notice visible thinning, uneven surfaces, or material loss. If you see glazing, burning, or unusual noises, it’s time for a change. Slower cutting and increased pressure can pose safety risks and lead to tool damage. Always match the disc type to your project and inspect it before use. Regular maintenance and proper storage can enhance disc lifespan. Keep going to discover tips for safe usage and effective performance.

Signs of Wear: How to Identify When Your Disc Is Past Its Prime

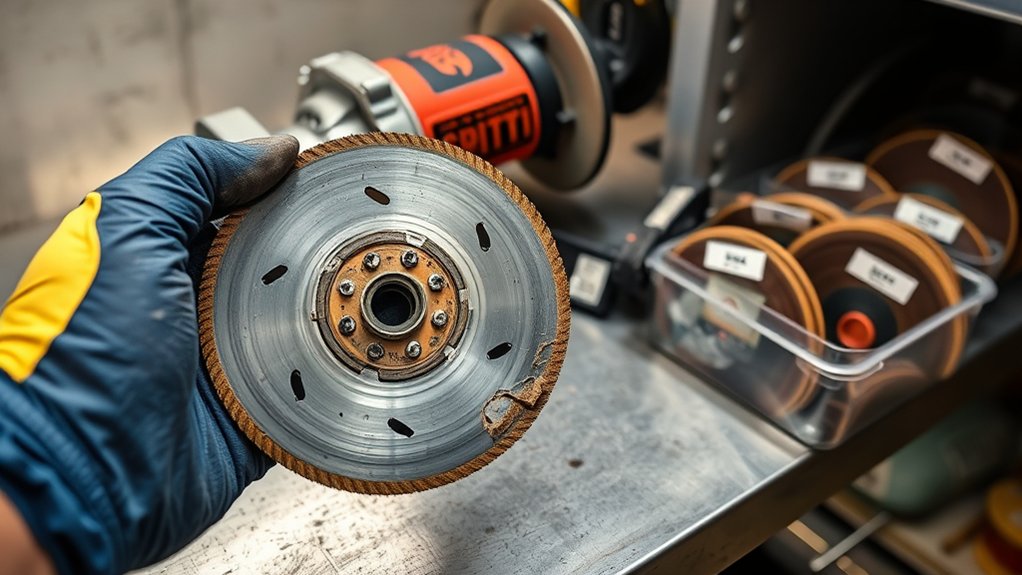

When you’re working with an angle grinder, it’s essential to regularly check the disc for signs of wear, as neglecting this can lead to poor performance or even accidents. First, inspect for worn discs showing visible thinning, uneven surfaces, or significant material loss. If you notice loading or glazing—where the surface appears shiny and smooth—it’s time to replace the disc, as this indicates clogged abrasive grains.

Watch for any burning or discoloration, like blue or brown spots, which signal heat damage and reduced effectiveness. Additionally, listen for unusual noises, such as squealing or grinding, as these could mean cracks or internal damage. Finally, if you find that cutting performance is decreasing, requiring more effort or longer removal times, those are clear signs it’s time for a new disc. Prioritizing these checks keeps your work efficient and safe.

How Slower Cutting Impacts Safety and Performance

Slower cutting can remarkably compromise both safety and performance, as it often leads to increased heat generation. A damaged disc can considerably impact your work, making it essential to recognize these issues early. Here are four ways slower cutting affects your operations:

- Overheating: Prolonged cutting can cause tool burnout, risking costly repairs.

- Increased Pressure: As performance drops, you might apply more pressure, risking stability and control.

- Surface Finish: Dull discs produce rough results, leading to time-consuming rework and frustration.

- Operator Fatigue: Slower cutting can wear you down, impairing focus and reaction times, which elevates safety risks.

Monitoring cutting speed can help you spot wear early, prompting timely disc replacements that enhance both safety and performance. Prioritize your tools and your well-being by staying vigilant about disc conditions.

Choosing the Right Disc Type for Your Project

Choosing the right disc type for your project is essential for achieving the best results. Consider the material you’re working with, as each disc is designed for specific tasks—like grinding, cutting, or sanding. Always check compatibility with your angle grinder to guarantee safety and peak performance.

Disc Material Considerations

Selecting the right disc material for your angle grinder is essential to achieving the best results in your project. Here are some key disc material considerations to keep in mind:

- Metalworking: Use aluminum oxide or zirconia discs for durability and heat resistance.

- Concrete and Masonry: Opt for diamond discs to handle high abrasion and guarantee clean cuts.

- Wood Applications: Choose carbide-tipped or TCT discs to minimize tear-out and enhance cutting efficiency.

- Disc Thickness: Thinner discs (1-2 mm) are ideal for cutting, while thicker discs (3-5 mm) work better for grinding.

Project-Specific Disc Selection

After understanding the importance of disc material, you’ll want to focus on how to choose the right disc type for your specific project. Selecting the appropriate disc type is essential for achieving the best results.

Here’s a quick guide to help you decide:

| Project Type | Recommended Disc Type | Key Features |

|---|---|---|

| Concrete | Diamond Cutting Disc | Ideal for hard materials |

| Metal Smoothing | Flap Disc | Great for blending and finishing |

| Wood Cutting | Carbide-Tipped Disc | Reduces kickback, superior performance |

| Heavy Grinding | Thick Grinding Disc | Best for heavy material removal |

Always consider the RPM rating and specific grit size for precision. This project-specific disc selection guarantees efficiency and safety, empowering your work.

Why Using a Worn Disc Poses Safety Risks

Using a worn angle grinder disc can create serious safety hazards. You might notice signs of wear, like excessive vibrations or a dull cutting edge, which can lead to accidents and injuries. Regularly checking and replacing these discs is essential to maintaining a safe working environment.

Signs of Disc Wear

How can you tell if your angle grinder disc is nearing the end of its life? Recognizing the signs of wear is essential for your safety and efficiency. Look out for these key indicators:

- Chipping or Cracking: Any visible damage can lead to catastrophic failure.

- Glazed Surface: A shiny finish means the disc has lost cutting effectiveness.

- Burning or Discoloration: This indicates overheating, risking both the disc’s integrity and fire hazards.

- Increased Vibrations: More vibrations suggest instability and can lead to accidents.

Regularly inspect your discs for changes in diameter and thickness. Using a worn disc compromises your work and can result in serious safety risks. Stay vigilant!

Consequences of Worn Discs

While it might seem convenient to push through with a worn angle grinder disc, doing so can lead to serious safety hazards. The consequences of worn discs include unexpected breakage, which can send dangerous fragments flying, risking injury to you and bystanders. Increased friction from a dull disc generates excessive heat, potentially causing overheating and equipment failure. Furthermore, you’ll need to apply more force to achieve cuts, raising the chances of losing control. Worn discs often show signs like chipping or glazing, resulting in poor surface finishes that require rework, wasting your time and resources. Regularly inspect it closely and replace discs promptly to maintain safety, precision, and overall work quality. Don’t compromise your safety for convenience.

Safety Practices for Replacement

Continuing from the discussion about the dangers of worn discs, safety practices during replacement can’t be overlooked. Using a worn disc can lead to serious risks, so here’s how to maintain safety:

- Inspect Regularly: Check for thinning, glazing, or overheating signs before each use.

- Replace on Schedule: Implement a routine replacement based on your frequency of use.

- Secure Work Area: Guarantee your workspace is clear of unnecessary items to prevent accidents.

- Use Protective Gear: Always wear safety goggles, gloves, and appropriate clothing.

Essential Maintenance Tips for Maximizing Disc Lifespan

Maintaining your angle grinder discs is essential for ensuring their longevity and performance. Regular inspections can help you spot signs of wear, such as thinning, chipping, or glazing. Proper storage and cleaning also play significant roles.

| Maintenance Tip | Description |

|---|---|

| Inspect for Wear | Check for excessive thinning or chipping. |

| Clean After Each Use | Remove debris and resin to enhance effectiveness. |

| Store Properly | Keep discs in a dry, stable environment. |

| Monitor Expiration Dates | Be aware of resin-bonded discs’ lifespan. |

| Follow Manufacturer Guidelines | Adhere to usage recommendations for longevity. |

Inspection Checklist: What to Look for Before Each Use

Before you start using your angle grinder, it’s crucial to inspect the disc thoroughly to guarantee safe and effective operation. Use this inspection checklist to verify you’re ready to work safely:

- Examine for Wear: Check for excessive thinning or uneven surfaces, which can compromise cutting performance.

- Look for Glazing: Identify any shiny, smooth areas indicating clogged abrasive grains that diminish effectiveness.

- Check for Damage: Inspect for chips, cracks, or burn marks that suggest overheating or excessive wear—signs that replacement may be necessary.

- Listen for Unusual Noises: Pay attention to any strange sounds or vibrations during use, as these can signal underlying issues with the disc.

Choosing the Right Angle Grinder Disc Replacement

Choosing the right replacement disc for your angle grinder is essential for achieving peak performance and safety. First, identify the specific task at hand: use grinding discs for shaping metal or cutting discs for slicing through materials. Inspect your current angle grinder disc for visible wear like thinning, chipping, or glazing—these are signs it’s time for a replacement. Confirm the new disc matches your grinder’s specifications, including size (like 4.5-inch or 5-inch) and RPM rating, to avoid accidents. When selecting a disc, consider the material type; diamond discs excel at cutting hard materials like concrete, while flap discs are ideal for metal finishing. Regularly replacing worn discs not only boosts efficiency but also minimizes hazards. Remember, maintaining a sharp, compatible angle grinder disc is key to a safe and productive workspace.

Storage Tips to Keep Your Discs in Top Condition

Proper storage is essential for keeping your angle grinder discs in prime condition and extending their lifespan. Follow these storage tips to guarantee your discs stay safe and effective:

Proper storage is key to maintaining your angle grinder discs and ensuring their longevity and effectiveness.

- Cool, Dry Environment: Store discs away from direct sunlight and moisture to prevent degradation.

- Padded Containers: Use protective cases to minimize impact damage, avoiding cracks or chips.

- Organized and Labeled: Keep discs clearly marked and organized to quickly find the right type for your projects.

- Avoid Stacking: Don’t place heavy items on stored discs to prevent deformation and maintain their shape.

Regularly inspect your stored discs for signs of wear, like cracks or flaking. Replace any that show damage to guarantee safety and efficiency during use. By implementing these storage tips, you’ll keep your angle grinder discs in prime condition and ready for action whenever you need them.

Best Practices for Replacing Your Angle Grinder Disc?

Replacing your angle grinder disc is essential for maintaining peak performance and safety. Always inspect the disc for signs of wear before each use. Look for excessive thinning, chipping, or glazing. If you notice decreased cutting performance—like longer material removal times or increased effort—it’s time to replace the grinder disc. Unusual noises or vibrations during operation can indicate damage, so don’t hesitate to swap it out immediately to avoid accidents or tool damage.

Verify that the replacement disc matches your angle grinder’s specifications, including size and type, to maintain safety and efficiency. Don’t forget to store your replacement discs in a dry, stable environment. This helps prolong their lifespan and prevents deterioration caused by humidity or temperature changes. By following these best practices, you empower your work and guarantee a safer, more efficient grinding experience.

Frequently Asked Questions

How Do I Know When to Change the Angle Grinder Disc?

You’ll know it’s time to change the angle grinder disc when you notice disc wear, decreased performance signs like slower cutting, unusual noises, or overheating. Regularly inspect your disc to guarantee peak safety and effectiveness.

How to Tell When an Angle Grinder Blade Is Bad?

You can tell an angle grinder blade’s bad by inspecting for disc wear indicators like cracks or uneven surfaces. Use inspection techniques like listening for unusual noises and checking for loading or glazing to confirm safety.

How Do I Choose the Right Grinder Disc?

To choose the right grinder disc, match the disc material types to your project, guarantee size compatibility with your angle grinder, and select the appropriate grit for the task’s demands. Safety first, always!

When Changing a Grinding Disc, Two Safety Precautions That You Should Take Are?

When changing a grinding disc, prioritize grinding safety by disconnecting the tool and wearing PPE. Conduct a thorough disc inspection for cracks or damage to guarantee a secure and effective setup for your work.

Conclusion

To sum up, keeping your angle grinder discs in top shape is essential for both safety and efficiency. Did you know that using a worn disc can increase cutting time by up to 40%? Regularly inspecting your discs and knowing when to replace them can greatly enhance performance. By following best practices and choosing the right type for your project, you’ll guarantee a smoother, safer experience. Stay vigilant, and keep your tools ready for action.