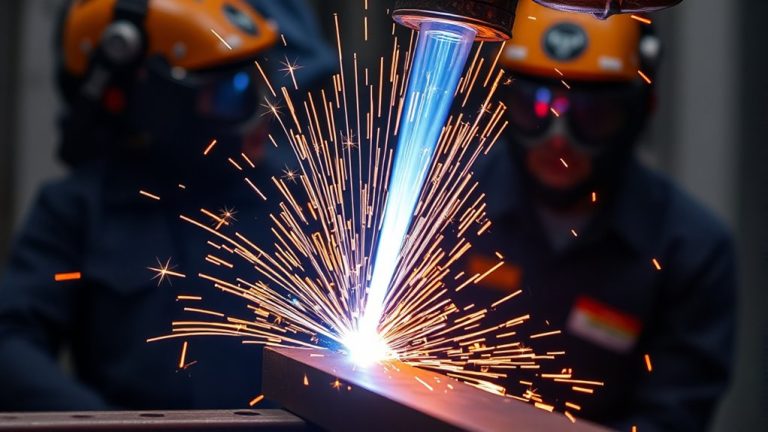

Plasma cutters transform compressed gas into a focused, high-temperature plasma arc that slices through conductive metals with impressive precision and speed.

This corrected guide tightens the numbers (thickness vs. amperage, noise, consumables) so you can choose the right system with confidence.

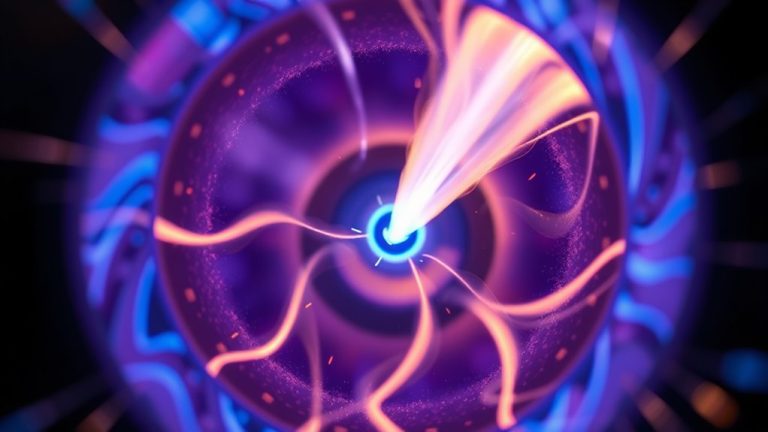

Understanding Plasma Cutting Technology

Among modern metalworking methods, plasma cutting is one of the most efficient and versatile for precision fabrication.

The process relies on gas ionization to create a conductive arc that reaches temperatures

around 40,000 °F (~22,000 °C), melting the metal while the high-velocity gas jet ejects the molten material from the kerf.

Plasma cutting harnesses superheated ionized gas to slice metal with accuracy and speed that mechanical methods can’t match.

When you activate a plasma cutter, it forces air or process gases (e.g., air, oxygen, nitrogen, argon-hydrogen)

through a constricted nozzle and energizes them electrically to form a concentrated plasma jet.

Depending on the machine and gas, the process can clean-cut thin sheet up to thick plate at production speeds.

Configurations include handheld units, mechanized tables for production, and full CNC systems for complex geometries.

Recent advances—fine-feature torches, arc-voltage height control, and CAM nesting—improve both quality and throughput.

Essential Components of a Plasma Cutter

| Component | Function |

|---|---|

| Power Source | Provides controlled DC output to initiate and sustain the plasma arc |

| Plasma Torch | Houses consumables (electrode, nozzle, shield) and constricts gas to form the high-temperature jet |

| Gas/Air Supply & Filtration | Delivers clean, dry gas; air quality is critical for cut quality and consumable life |

| Work Lead (Ground Clamp) | Completes the electrical circuit through the workpiece |

| Cutting Table | Supports the work; water or downdraft tables manage fume and dross |

| CNC & Drives (mechanized) | Controls X-Y motion and torch height from CAD/CAM toolpaths for repeatable precision |

Materials and Thickness Capabilities

Plasma cuts any electrically conductive metal: mild steel, stainless, aluminum, copper, and brass.

Capacity depends on amperage, gas, torch type, and whether you’re handheld or mechanized.

The table below gives realistic, commonly published ranges for mild steel.

(Aluminum and stainless capacities are often slightly lower for “fine-feature” quality at the same amperage.)

| Amperage Class | Typical Clean/Recommended Cut | Severance (edge-quality) | Common Use |

|---|---|---|---|

| 30–45 A (handheld) | ~6–16 mm (1/4–5/8″) | up to ~25 mm (≈1″) | Light fabrication, auto repair, field work |

| 65 A (handheld/mech) | ~20 mm (3/4″) | to ~32 mm (1-1/4″) | General fab, ag equipment |

| 85 A (handheld/mech) | ~25 mm (1″) | ~32–38 mm (1-1/4–1-1/2″) | Heavy fab, maintenance |

| 105 A (mechanized capable) | ~32 mm (1-1/4″) | ~38–45 mm (1-1/2–1-3/4″) | Production cutting, plate |

| ~200 A mechanized | ~25–30 mm production clean; edge to ~38 mm | ~50–57 mm (≈2–2-1/4″) | High-throughput plate cutting |

| High-power HD (300–600 A) | Clean beyond 50 mm with specialty process | Specialized systems up to ~160 mm | Heavy industry, specialized jobs |

Reading the table: “Clean/Recommended” is the thickness you can cut consistently with good edge quality and speed. “Severance” is the maximum thickness you can separate, usually more slowly and with rougher edges.

Types of Plasma Cutting Systems

Handheld

Portable Versatile

Ideal for repair, field work, and artistic projects. With appropriate amperage, handheld units can clean-cut up to ~25 mm (typically 85 A class).

Mechanized & CNC

Production Precision

Automated motion delivers repeatable quality on thicker plate, supports high volume, nesting, and fine-feature cutting with proper height control.

Specialized systems (tube/pipe, bevel heads, drilling combos) target unique production needs. Some “high-definition” plasma processes further tighten kerf and angularity.

Choosing the Right Plasma Cutter for Your Needs

- Material & Thickness: Size amperage to your typical clean-cut thickness (see table). Avoid buying only for rare severance jobs.

- Duty Cycle: For sustained production, target 60–100% duty cycle at your working amperage.

- Power: Small units run on single-phase 120/230 V; industrial systems may require three-phase 380–480 V (region dependent).

- Air Quality: Dry, oil-free air extends consumable life and improves edges. Use proper filtration/dryers.

- Portability vs. Precision: Handheld for mobility; CNC tables for repeatable accuracy and throughput.

- Operating Costs: Budget for consumables, gas, filters, and fume control (downdraft or water table).

- Compliance: Look for CSA (Americas) and/or CE (EU). UL/ETL marks may appear on some models but are not universal; follow local code requirements.

Match amps to your routine thickness: e.g., 30–45 A for thin stock, 65–85 A for 12–25 mm, ~105 A for ~32 mm, and mechanized 200 A+ for heavy plate production.

- Noise: Typical plasma cutting produces about ~90–115 dB(A) near the arc. Always wear hearing protection.

- Fume: Use local extraction, downdraft, or water tables. Stainless and galvanized fume require extra caution.

- Wet Environments: Do not use handheld equipment in wet conditions. Submerged/underwater cutting is a controlled, mechanized process on water tables with specific procedures (e.g., managing hydrogen when cutting aluminum).

- PPE: Eye/face protection rated for arc glare, flame-resistant clothing, gloves, safety boots.

Frequently Asked Questions

How long do consumables last?

There isn’t a meaningful “hours” number—life depends on pierce count, meters of cut, gas quality, height control, amperage, and operator technique.

Focus on: dry air, correct pierce/cut height, proper amperage/nozzle pairing, and timely electrode changes to maximize life and consistency.

Can plasma cutters be used in wet environments?

Never operate standard handheld units in wet conditions due to shock risk. However, submerged mechanized cutting on water tables is a standard industrial method

when executed with proper insulation, procedures, and ventilation (especially when cutting aluminum).

What safety certifications should I look for?

Check for CSA (Americas) and/or CE (EU). Some models also carry UL/ETL listings. Always ensure compliance with your local electrical and safety codes.

How loud are plasma cutters?

Expect roughly ~90–115 dB(A) depending on current, table type, gas, and distance. Hearing protection (earmuffs/earplugs) is required in most scenarios.

Can plasma cutters be used with CNC machines?

Absolutely. CNC integration enables precise, repeatable motion, fine-feature cutting, automatic torch height control, and efficient nesting for minimal waste.

Conclusion

Your plasma cutter choice directly affects cut quality and operating cost. Size amperage to your routine thickness, secure adequate duty cycle and power,

and invest in air quality and fume control. Pairing the right machine with disciplined setup yields fast, accurate parts and predictable consumable spend.