You’ve likely encountered welds that demand exceptional precision and minimal heat distortion in critical applications.

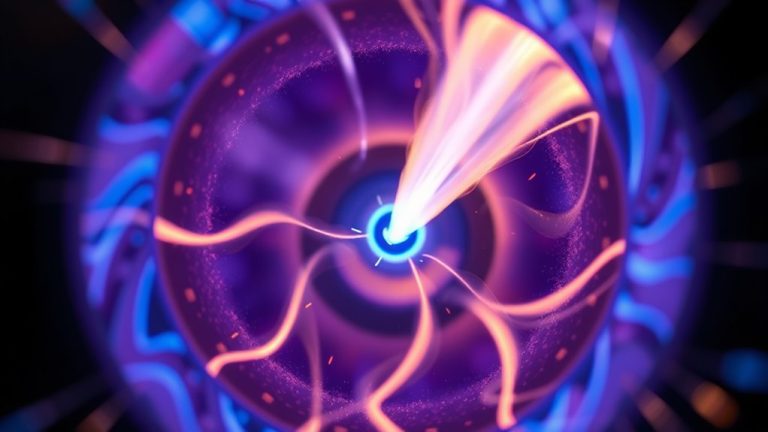

Plasma arc welding (PAW) delivers a tightly constricted arc and arc-column temperatures on the order of

10,000–20,000 °C (≈ 18,000–36,000 °F), enabling deep, narrow welds with excellent control.

Understanding PAW’s principles and capabilities can transform how you approach challenging materials like titanium and high-strength alloys in aerospace manufacturing.

What Is Plasma Arc Welding and How Does It Work?

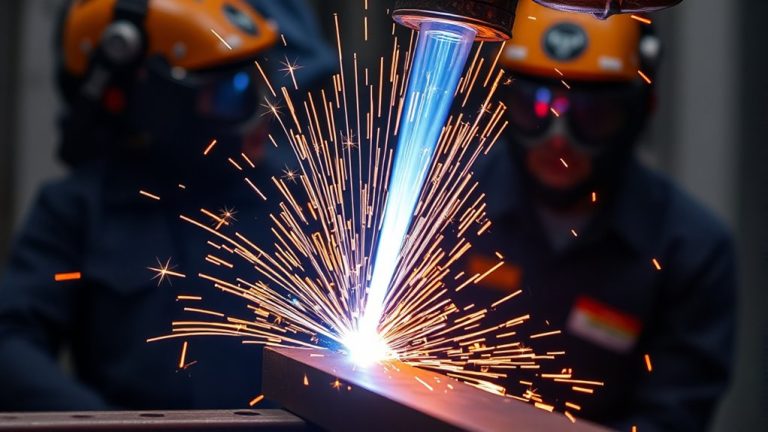

Plasma Arc Welding (PAW) is a high-precision welding process that uses a non-consumable tungsten electrode and a constricting copper nozzle to form a highly focused transferred arc to the workpiece.

A pilot arc inside the torch ionizes the plasma gas and ensures consistent main-arc starting.

The process commonly uses a dual-gas system: a plasma gas (e.g., argon or argon/hydrogen) through the orifice to create the arc jet, and a shielding gas (often argon or Ar-H2) around the weld pool to prevent atmospheric contamination.

Typical electrical parameters for welding are:

arc voltage ~18–35 V (OCV often ~60–80 V) and

current ranges of micro-plasma (≈ 0.1–15 A), medium (≈ 15–200 A), and keyhole mode (> 100 A).

Production PAW welds frequently fall in the ~50–350 A band, depending on material and thickness.

Because the jet is constricted, energy density is high, enabling deep, narrow fusion and excellent arc stability.

That stability, combined with precise gas and current control, is why PAW is favored for aerospace, medical, and electronics applications.

The Working Principle Behind Plasma Arc Welding Technology

In operation, you first ignite a low-current pilot arc between the tungsten electrode and the copper nozzle to ionize the plasma gas.

When the torch is positioned near the work, the main arc transfers to the workpiece (the transferred arc).

The constricted arc column runs at roughly 10,000–20,000 °C, and torch water-cooling manages the resulting heat load.

Fine control of current, arc voltage, and plasma/shield gas flow governs penetration, bead profile, and heat input.

Arc Formation Process

- Pilot arc ignition at low current stabilizes the plasma inside the torch.

- Plasma gas is constricted through a fine-bore nozzle, raising jet velocity and energy density.

- Main arc transfers to the workpiece, delivering a focused, controllable heat source.

Gas Ionization Mechanics

Electrical energy strips electrons from gas atoms, creating a conductive plasma of ions and free electrons.

The ionized jet responds to electromagnetic fields and to the orifice geometry, allowing you to constrict and direct the arc with high precision.

Temperature Control Systems

- Modern constant-current power supplies (DCEN; variable-polarity for certain aluminum/titanium jobs) regulate the heat input.

- Dual-gas strategy separates plasma generation from weld-pool shielding for stability and cleanliness.

- Water-cooled torches and precise gas flow keep the arc column stable in the ~10,000–20,000 °C regime.

Essential Equipment and Components for Plasma Arc Welding

Power Supply Systems

PAW uses constant-current DC (DCEN) for most materials and variable-polarity PAW where cathodic cleaning is needed (e.g., certain aluminum alloys).

Expect arc voltage around 18–35 V and a usable current envelope from sub-amp micro-plasma to >100 A keyhole mode.

Welding Torch Components

A water-cooled plasma torch houses the non-consumable tungsten electrode and copper nozzle (orifice).

The torch provides the pilot arc, constricts the jet, and routes both plasma and shielding gases.

Nozzle size, electrode setback, and gas flow tune arc stiffness and penetration.

Gas Delivery Equipment

- Plasma gas (commonly Ar or Ar-H2) flows through the orifice to form the jet.

- Shielding gas (often Ar or Ar-H2; He blends for certain jobs) protects the pool and bead.

- Flowmeters/regulators and mixers maintain repeatable flows for stability and cleanliness.

Key Advantages of Using Plasma Arc Welding

- Exceptional arc stability and high energy density for precise, repeatable welds.

- Deep, narrow fusion with smaller HAZ and low distortion compared with a diffuse TIG arc.

- Excellent performance on titanium, nickel alloys (e.g., Inconel), and stainless steels.

- High travel speeds; keyhole mode reduces passes on mid-thickness plate.

Notable Disadvantages and Limitations

- Equipment cost/complexity: torch cooling, consoles, and gas controls add capital and maintenance.

- Parameter sensitivity: keyhole mode requires tight control of current, gas flows, and fit-up.

- Consumables: nozzle/orifice wear and electrode care are critical to consistency.

- Access/ergonomics: torches are bulkier than GTAW, making some manual joints harder.

- Safety: intense UV/visible radiation and noise; robust PPE and shielding required.

PAW vs. Other Welding Methods

Compared with TIG (GTAW), PAW’s constricted jet offers deeper penetration at a given current and better tolerance to small stand-off variations.

Relative to MIG (GMAW), PAW emphasizes precision over highest deposition rates.

Laser and EB can exceed PAW in penetration or speed, but at higher equipment cost and stricter joint prep—PAW often sits in the sweet spot for precision vs. cost.

Industrial Applications and Use Cases

- Aerospace: titanium and nickel-alloy components, thin-wall tubing, precision seams.

- Automotive & energy: stainless tube and sensor housings, hard-to-reach joints.

- Medical & electronics: clean, small HAZ welds on thin or heat-sensitive parts.

Automation and Robotic Integration

PAW integrates well with mechanized systems and industrial robots for high repeatability, real-time monitoring, and long production runs.

Variable-polarity PAW (VPPAW) remains a notable option for certain aluminum/titanium applications in automated setups.

Future Trends and Developments

- Smarter power sources with advanced waveform control and parameter analytics.

- AI-assisted process control for adaptive keyhole stability and defect prevention.

- More accessible systems as vendors simplify consoles/torches and lower ownership costs.

Frequently Asked Questions

What PPE is required?

Auto-darkening helmet (proper shade), UV-rated safety glasses, heat-resistant gloves, flame-resistant clothing, safety footwear, and adequate fume extraction/ventilation. Use screens/curtains to protect bystanders.

How much does a PAW setup cost?

Costs vary widely by amperage class, duty cycle, console features, torch variant, cooling, and automation. Request vendor quotes for current pricing and spares packages.

What certifications/training fit PAW work?

Qualify procedures and personnel per the applicable code (e.g., AWS D17.1 for aerospace; general qualification via AWS B2.1).

Manufacturers’ PAW courses help with torch maintenance and parameter setup.

Can PAW be performed outdoors/windy?

Avoid unshielded winds. For gas-shielded welding, use enclosures/windscreens and keep wind at the weld to ≤ 5 mph to maintain shielding.

What routine maintenance is required?

- Regular electrode inspection/dressing and scheduled nozzle/orifice replacement.

- Torch cleaning, gas line checks, coolant inspection, and leak checks.

- Calibration of flowmeters and confirmation of interlocks/safety devices.

Conclusion

Plasma arc welding offers a controllable, high-energy-density arc for deep, precise welds with a compact HAZ.

Match your power class and torch to the joint thickness (e.g., micro-plasma for ultra-thin; keyhole for mid-thickness),

and use disciplined gas/power control to realize PAW’s full benefits—especially on titanium and high-strength alloys.