Imagine a sword forged from lightning—this is the essence of plasma cutting. You’ll find that understanding this technology involves grasping the intricate dance of electricity and ionized gas. Each component, from the torch to the electrode, plays a crucial role. As you explore the precision and speed of this cutting-edge technique, consider its applications in fields like automotive repair and construction. Discover how mastering plasma cutting could revolutionize your projects.

Understanding Plasma and Its Properties

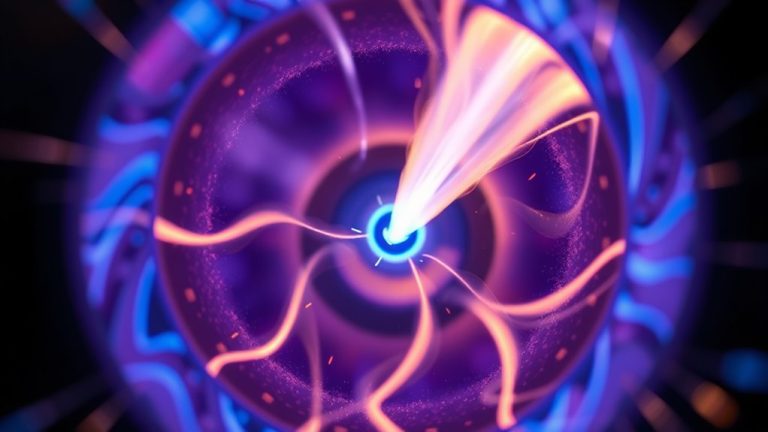

Plasma, the enigmatic fourth state of matter, possesses unique properties that make it invaluable in cutting technologies. As an ionized gas, plasma contains free-moving electrons and ions, rendering it electrically conductive.

Plasma, as the mysterious fourth state of matter, is key in cutting technologies due to its electrical conductivity.

When you apply extreme heat to a gas, this ionization creates a high-temperature environment, reaching temperatures up to 40,000°F. Such intense heat allows plasma to efficiently melt and cut through electrically conductive materials like steel and aluminum.

The cutting arc generated from this ionized gas is a result of its high-temperature nature. This arc is vital for melting the metal’s surface, turning it into molten metal.

During the cutting process, the high-speed gas flow removes this molten material, ensuring cleaner cuts compared to traditional methods. These properties not only make plasma cutting precise but also incredibly effective, particularly when dealing with thick or tough materials requiring intricate cuts.

The Evolution of Plasma Cutting Technology

While plasma cutting technology traces its roots back to the 1960s, it wasn’t until the 1980s that it truly began to shine with the advent of sheet metal and plate material applications. The plasma cutting process evolved considerably with the introduction of CNC plasma cutters in the late 1980s and 1990s, allowing for more intricate and flexible designs. Unlike early models, which were large and costly, modern plasma torches achieve near-laser precision with thinner arcs, enhancing cutting speed and reducing post-cut processing.

| Era | Advancements | Impact |

|---|---|---|

| 1960s | Plasma welding origins | Industrial settings, limited use |

| 1980s-1990s | CNC technology introduction | Complex shapes, flexibility |

| 2000s-Present | Affordable, precise plasma torches | Artistic and DIY accessibility |

Today, high voltage plasma cutters are more accessible, cutting conductive materials with precision in various settings. Whether you’re in industrial settings or engaging in DIY projects, modern plasma cutters offer unparalleled efficiency and creativity.

Key Components of a Plasma Cutting System

In understanding the essential parts of a plasma cutting system, you’ll recognize the power supply, arc starting console, and plasma torch as critical components.

The power supply converts AC line voltage to a high DC voltage necessary for generating the plasma arc, while the arc starting console uses high-frequency AC voltage to ionize the gas and initiate cutting.

Equipped with consumables like the electrode and nozzle, the plasma torch plays a crucial role in maintaining the arc and ensuring precise cuts, with different gases and current densities optimizing performance for conventional and precision systems.

Essential Equipment Parts

A plasma cutting system‘s precision and efficiency stem from its well-engineered components. The power supply is essential, converting AC line voltage to 200-400 VDC to maintain a stable cutting arc.

Your plasma torch, equipped with an electrode and nozzle, is important for directing the plasma jet, while the arc starting console uses high-frequency AC voltage (~5,000 VAC at 2 MHz) to initiate the arc.

Precision plasma systems excel by utilizing multiple gases and achieving higher current densities of 40-50K amps/in², resulting in cleaner, more precise cuts.

Consumables like the electrode and nozzle require regular monitoring and replacement to guarantee peak cutting performance.

Each part plays a significant role, guaranteeing your cutting operations are both precise and efficient.

Plasma Torch Functionality

When exploring the functionality of a plasma torch, you’ll discover it’s composed of several key components that are vital for its operation.

The plasma torch’s electrode generates a high-frequency spark, ionizing the gas and creating an electric arc. This shift forms the plasma used to cut the work piece.

A swirl ring plays an important role by producing a gas vortex, stabilizing the arc, and enhancing cut quality. The nozzle constricts this plasma flow, focusing the energy for precise cuts.

Your cutting machine may use various gases—like air, nitrogen, or argon—depending on the material and precision needed. For enhanced accuracy, a secondary shielding gas constricts the arc further, delivering cleaner cuts with superior precision.

These elements guarantee efficient and effective cutting operations.

Operational Mechanisms of Plasma Cutters

To understand the operational mechanisms of plasma cutters, you’ll first need to focus on how plasma arc formation occurs.

The process begins by forcing a gas through a constricted nozzle while a high-frequency spark or pilot arc ionizes the gas, creating plasma.

This plasma jet, reaching temperatures up to 40,000°F, efficiently melts the metal, and high-speed gases blow away the molten material, completing the cutting process.

Plasma Arc Formation

Although plasma cutting might seem complex, understanding plasma arc formation is essential for mastering its operational mechanisms. The process begins with a gas, like oxygen or argon, forced through a nozzle and ionized by a high-frequency spark.

This ionized gas forms a plasma arc, creating a plasma jet that reaches extreme temperatures, capable of slicing through electrically conductive materials. The plasma jet not only melts but also expels molten debris, ensuring a clean cutting process.

For precision, a secondary shielding gas constrains the plasma arc, enhancing cut quality and reducing oxidation.

- Plasma arc: Initiated by a high-frequency spark, enabling rapid material piercing.

- Plasma jet: Reaches up to 40,000°F, melting materials effectively.

- Secondary shielding gas: Improves cut quality by minimizing oxidation.

Cutting Process Steps

Mastering the plasma arc formation sets the stage for understanding the precise steps involved in the cutting process of plasma cutters.

Plasma arc cutting begins when pressurized gas, like air or nitrogen, moves through a constricted nozzle, ionizing to form plasma. The cutting process is triggered by the pilot arc, creating a small arc before contact, or a high-frequency spark when the torch touches the workpiece. This forms a continuous electrical circuit, allowing high-speed gas to blow away molten metal.

Regularly monitor and replace consumables like electrodes and nozzles for peak performance.

With CNC cutting technology, you can automate the process, precisely cutting shapes on the computer with advanced programming options, providing adjustments for piercing and cutting speed.

Safety Precautions and Best Practices in Plasma Cutting

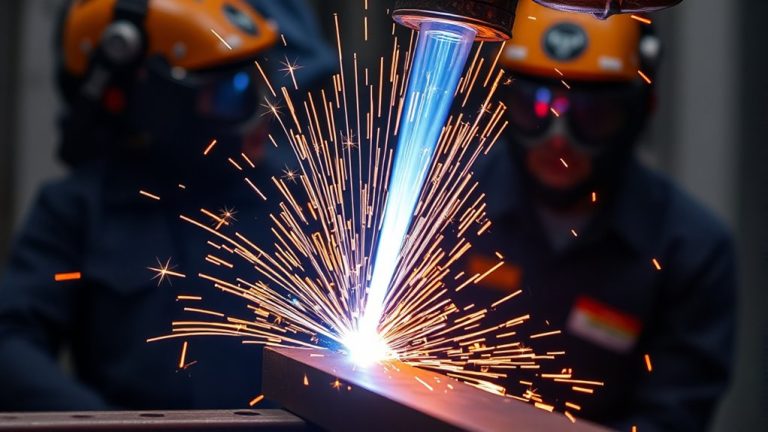

Guaranteeing safety in plasma cutting is vital, as the process involves hazards like intense light, sparks, and harmful fumes. Implementing proper safety precautions is essential.

Always wear protective gear—lens shade #5 or higher, gloves, and flame-resistant clothing—to guard against injuries from sparks and intense light. Maintaining a clean work area is important; sparks can travel up to 1.5 meters, posing fire risks if flammable materials are present.

Proper ventilation in your workspace prevents the inhalation of harmful fumes, safeguarding your health. Regularly inspect and maintain plasma cutting equipment, especially consumables like electrodes and nozzles, to guarantee peak performance and safety.

- Protective Gear: Use lens shade #5+, gloves, flame-resistant clothing.

- Clean Work Area: Keep free of flammable materials to avoid fires.

- Ventilation: Guarantee proper airflow to mitigate harmful fume inhalation.

Additionally, obtaining training on equipment operation enhances safety and efficiency.

Evaluating Cut Quality and Electrode Longevity

To achieve ideal results in plasma cutting, understanding the factors that influence cut quality and electrode longevity is crucial. The symmetry of your cuts depends on optimal settings like cutting speed, arc current, standoff distance, and gas pressures.

If your kerfs are wider at the top, your cut quality might suffer, producing asymmetrical edges. Adjusting these parameters guarantees cleaner cuts and boosts performance.

Electrode longevity is another critical aspect. Plasma cutting electrodes wear out over time, especially if the hafnium insert is large, as it generates more heat and wears faster.

Regularly monitoring electrode wear is essential to avoid poor cut quality and escalating operational costs. Replacing electrodes before they degrade considerably helps maintain consistent performance.

Your ability to evaluate and adjust these factors directly impacts the operational efficiency and cost-effectiveness of your plasma cutting operations, assuring you achieve the best possible results.

Applications and Future Trends in Plasma Cutting

Plasma cutting has found numerous applications across a variety of industries, thanks to its ability to precisely and swiftly slice through metals. In automotive repair and construction, plasma cutting‘s high precision and speed make it ideal for fabricating components and structures.

The integration of CNC technology allows for the production of complex shapes with consistent accuracy, expanding its use in custom fabrication and artistic metalworking.

Future trends in plasma cutting focus on enhancing energy efficiency and precision. The development of new gas mixtures promises to improve cutting capabilities while reducing operational costs.

New gas mixtures in plasma cutting aim to boost efficiency and precision while lowering costs.

Moreover, plasma cutting’s role in environmentally friendly practices is growing, particularly through underwater cutting techniques that minimize the heat-affected zone and noise pollution.

- Affordable handheld models have made plasma cutting accessible for DIY projects and small businesses.

- CNC advancements enable intricate designs in various metals with high precision.

- Emerging gas technologies aim to enhance cost-effectiveness and environmental benefits.

Frequently Asked Questions

How Does a Plasma Cutter Actually Work?

You initiate the cutting process by creating a plasma arc using thermal energy. The precise nozzle design directs gas types, ionizing them for electrical conductivity. Ascertain cutting precision and follow safety precautions for effective use.

Will a 20 Gallon Air Compressor Run a Plasma Cutter?

A 20-gallon air compressor can run a plasma cutter, but it’s not always smooth sailing. Consider power requirements, duty cycle, and efficiency levels. For greater cutting thickness, opt for a compressor with enhanced features and capacity.

What Is a Disadvantage of Plasma Cutting?

A disadvantage of plasma cutting is its power consumption, which can lead to higher operational costs. Additionally, it requires operator skill for precise cuts, has maintenance needs, and its portability issues limit efficiency in diverse work environments.

What Metals Can Plasma Not Cut?

You can’t cut extremely thick aluminum alloys or stainless steel with plasma, especially over 150 mm. Copper sheets, titanium metals, brass components, and high carbon steel also pose challenges due to heat dissipation. Cast iron requires alternative methods.

Conclusion

You’ve explored the intricacies of plasma cutting, understanding its properties, tracing its technological evolution, and dissecting its key components. You’ve learned how to operate plasma cutters, ensuring safety while evaluating cut quality and electrode longevity. You’ve discovered its diverse applications and envisioned its future trends. By mastering these elements, you not only enhance your technical prowess but also position yourself at the forefront of cutting-edge fabrication techniques, ready to tackle any project with precision and efficiency.