Imagine you’re about to cut through a steel sheet with a plasma cutter, but you’re unsure where to start. Don’t worry; there’s a straightforward process to follow that guarantees safety and precision. Begin by setting up your cutter and air compressor, making certain they’re well-maintained. Your workspace should be clean and ventilated, with personal protective gear ready. Understanding these essentials is just the beginning—a deeper exploration will lead you to mastering plasma cutting.

Understanding the Plasma Cutting Process

Plasma cutting is a fascinating and efficient process that you can master with a bit of understanding and practice. It involves using plasma, an electrically heated, ionized gas, to slice through electrically conductive materials.

The cutting process begins with a pilot arc, formed between the cutter’s electrode and the workpiece, which ionizes the gas and starts the cutting. You don’t need to preheat the metal, unlike oxy-fuel cutting, allowing quicker setups and efficient cutting of thicker materials.

The pilot arc initiates the cutting without preheating, enabling faster setups and efficient cutting of thicker materials.

To achieve a maximum clean cut, focus on adjusting the cutting speed, power supply, and air supply. These must be calibrated according to the material’s thickness.

Handheld plasma cutters offer versatility and can effectively tackle materials like mild carbon steel, stainless steel, aluminum, and copper.

Always guarantee safety by monitoring amperage settings and maintaining proper air pressure to secure precision and prevent accidents during the cutting process.

Essential Equipment and Setup for Plasma Cutting

To start plasma cutting safely and effectively, verify you have the right equipment, including a well-maintained plasma cutter and an air compressor capable of delivering at least 3.5 scfm at 70-120 psi.

Set up your cutter on a stable surface, check all connections, and inspect the torch for clean consumables to guarantee smooth operation.

Don’t forget your personal protective equipment—gloves, goggles, and a fire-resistant jacket are essential to protect against sparks and intense heat.

Key Plasma Cutter Components

Mastering the essentials of plasma cutting starts with understanding its key components.

The power supply is fundamental, delivering the necessary electricity—either 110V or 220V—depending on your plasma cutter model. Make sure it’s connected to a stable source to avoid interruptions.

The torch, armed with the right consumables like electrodes and nozzles, is critical for achieving your desired cutting thickness. Choose consumables that match your task for efficient cuts.

Compressed air is essential, with a requirement of 70-120 psi for peak performance. Securely connect the work lead to the workpiece, guaranteeing a solid ground.

Finally, a clean and dry gas supply prevents malfunctions, safeguarding the entire process and guaranteeing a smooth cutting experience.

Prioritize safety and precision in every step.

Proper Air Compressor Setup

How essential is it to set up your air compressor correctly when diving into plasma cutting? It’s critical for achieving ideal plasma cutter performance.

Start by confirming your air compressor delivers a clean air supply with a minimum psi pressure of 80, though some systems may need 115 psi. Use an air dryer to remove moisture and contaminants, preventing potential damage.

Secure connections between the air hose and plasma cutter are fundamental; they maintain consistent air pressure throughout the operation. Always check air pressure against the manufacturer’s specifications before starting the cutting process.

These steps guarantee your equipment runs smoothly and safely, enhancing precision and extending the lifespan of your plasma cutter. Proper setup is your first step to success.

Essential Safety Gear

Safety is paramount when you’re diving into the world of plasma cutting. It’s critical to wear protective gear to shield yourself from potential hazards.

Here’s a breakdown of essential personal protective equipment:

- Welding Helmet and Dark Shades: A welding helmet with a shade rating of at least 8 is necessary to protect your eyes from the bright arcs and flying debris.

- Fire-Resistant Clothing: Don a fire-resistant jacket and heavy-duty welding gloves to safeguard against sparks. Make sure your clothing is fully fire-resistant to prevent ignition.

- Foot and Ear Protection: Closed-toed shoes guard against heavy materials, while ear plugs help mitigate noise from the plasma cutter.

Lastly, don’t overlook proper ventilation to disperse harmful gases and smoke, making certain a safe workspace.

Safety Protocols and Protective Gear

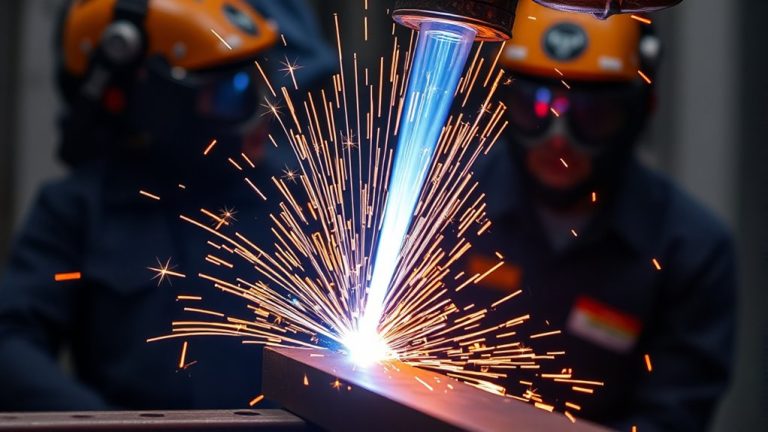

When engaging in plasma cutting, adhering to essential safety protocols is vital to guarantee both your safety and the quality of your work.

Start by wearing personal protective equipment (PPE) including heavy-duty welding gloves and a fire-resistant jacket. These protect you from sparks and the intense heat generated. Dark shades with a minimum shade rating of 8 shield your eyes from harmful glare, while closed-toed shoes safeguard your feet.

Ensure your workspace is well-ventilated to minimize exposure to toxic fumes and gases produced during cutting. Always keep flammable materials far from the cutting area to prevent fires caused by sparks or molten metal.

Proper grounding of the workpiece is important to avoid electric shock, as plasma cutters operate at high voltages.

Regularly inspect protective gear for any damage, replacing worn items promptly. By following these safety protocols, you’ll maintain a secure and efficient cutting environment.

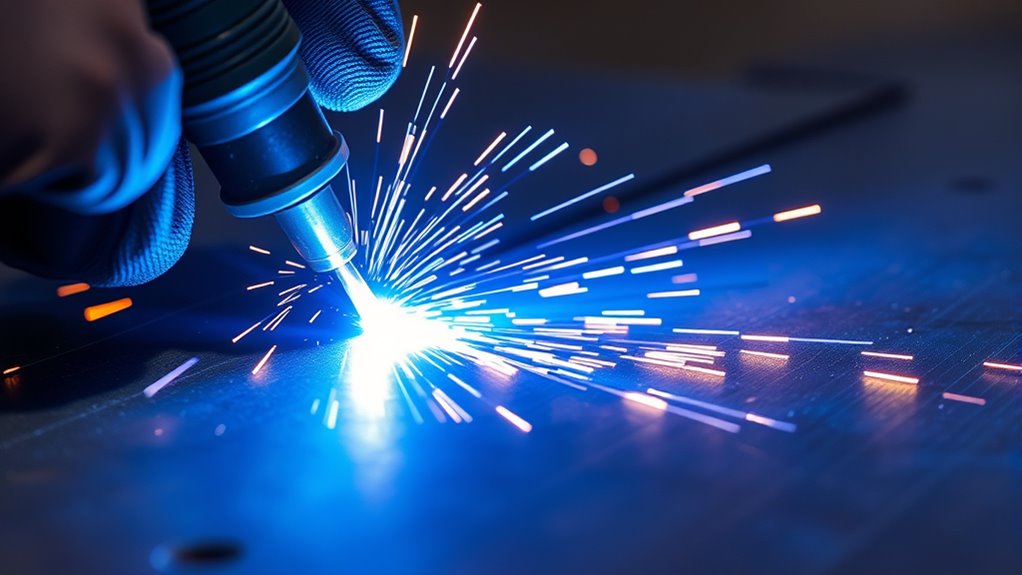

Techniques for Achieving Precision Cuts

Mastering the techniques for achieving precision cuts with a plasma cutter requires careful attention to detail and a steady hand. Start by holding the plasma cutting torch at a 90-degree angle to the metal surface. This guarantees you achieve straight and clean cut thickness consistently.

Hold the plasma torch at a 90-degree angle for consistently straight and clean cuts.

Here are key tips to enhance your cutting precision:

- Utilize a Drag Shield: Attach a drag shield extension to your torch. This tool helps maintain a consistent distance from the workpiece, giving you better control for precision cuts.

- Maintain a Steady Cutting Speed: A stable speed is essential. Cutting too slowly causes excessive heat, widening the kerf, while a fast pace can leave cuts incomplete.

- Pre-mark Your Cut Lines: Use a marker to outline your cuts on the metal. This guide is invaluable, especially when dealing with intricate shapes or angles.

Always start the arc slightly off the edge, tilting the torch for a complete, efficient cut.

Maintenance and Replacement of Consumables

To guarantee peak performance and safety in your plasma cutting operations, regularly inspect and replace consumables like electrodes and nozzles based on their usage lifespan.

Keep an eye out for signs of wear such as pitting or distortion, which can compromise cutting quality and lead to potential hazards.

Investing in high-quality consumables and storing them properly can optimize their performance and minimize downtime, so track their use diligently with a maintenance log.

Consumable Lifespan Considerations

Although often overlooked, the maintenance and replacement of consumables like electrodes and nozzles are essential to ensuring peak performance of your plasma cutter.

Regular inspection is vital to maintain cutting quality and avoid costly machine damage. Here’s how you can maximize the lifespan and efficiency of your consumables:

- Monitor Cutting Time: Replace consumables every 8 to 10 hours of cutting, depending on material thickness and conditions.

- Ensure Proper Supply: Keep a sufficient stock of high-quality consumables to prevent workflow interruptions and maintain efficiency.

- Practice Proper Maintenance: Regularly clean the torch and check that the air supply is free of moisture and contaminants. This prevents premature wear and extends consumable lifespan, reducing long-term costs.

Stay proactive with these practices for best results.

Identifying Worn Components

Recognizing worn components in your plasma cutter is essential for maintaining optimal performance and ensuring safety. Regularly inspect your plasma torch’s consumables, focusing on electrodes and nozzles.

Worn electrodes can cause uneven cuts and excess dross. Check for a visibly eroded tip or a rounded edge, replacing them every 1-3 hours of use.

Examine nozzles for a larger or irregularly shaped orifice, which can destabilize the plasma arc. Additionally, assess the drag shield; excessive scorching or cracking can lead to contamination and imprecise cuts.

Keeping these parts in top shape is vital for ideal cutting performance. Always maintain a stock of high-quality consumables to avoid frequent replacements and reduce operational costs while enhancing overall maintenance efficiency.

Optimizing Consumable Performance

Maintaining ideal performance from your plasma cutter requires diligent attention to the maintenance and replacement of consumables. Regularly inspect components like electrodes and nozzles for wear to maintain cutting efficiency and power.

Follow these steps:

- Inspect and Clean: Frequently check your torch and clean it to prevent contamination, which can degrade cut quality over time.

- Replace as Needed: When signs of erosion appear, replace consumables promptly. Always use compatible parts to avoid operational issues and guarantee efficiency.

- Stock Up: Keep a good supply of consumables on hand. These low-cost items are essential for minimizing downtime and maintaining peak performance.

Troubleshooting Common Plasma Cutting Issues

When facing challenges with your plasma cutting process, it’s crucial to systematically troubleshoot common issues to maintain safety and efficiency. Start by checking the power supply and confirm it’s properly grounded. Verify the air pressure is adequate by connecting the air compressor correctly.

Begin troubleshooting plasma cutting by ensuring the power supply is grounded and air pressure is correctly connected.

If the cutting tip fails to start, the pilot arc might be the issue. Inspect the torch consumables, such as electrodes and nozzles, for wear or damage.

Frequent clogging of the nozzle can be a result of moisture or contaminants; using an air filter and dryer guarantees a clean air source.

For poor cut quality or excessive dross, adjust the amperage settings and travel speed according to the material thickness.

Finally, if cuts are inconsistent, examine your torch’s angle and distance from the workpiece. Improper positioning can lead to uneven cuts and heat distortion, so always maintain the correct stance.

Frequently Asked Questions

What Are Some Common Mistakes Made With Plasma Cutting?

You might make common errors like incorrect plasma cutter setup or ignoring safety precautions. Guarantee proper material thickness settings, maintain consumables, and adjust cutting speed. Practice on scrap and check air pressure for smooth operation.

Will a 20 Gallon Air Compressor Run a Plasma Cutter?

Yes, a 20-gallon air compressor can run a plasma cutter if it meets 70-120 psi and proper SCFM. Verify compressor capacity aligns with plasma cutter efficiency, consider cutting thickness capability, noise, power source, and maintenance for peak performance.

What Does 2T and 4T Mean on a Plasma Cutter?

On a plasma cutter, 2T and 4T refer to trigger modes. 2T requires continuous trigger pressure, offering more control, while 4T lets you release it for long cuts. Both settings enhance plasma cutting techniques, safety, and efficiency.

What Psi Should I Run My Plasma Cutter At?

You’ll want to set your plasma cutter’s pressure between 70 and 120 psi. Adjust air pressure based on cutting thickness and efficiency. Make certain your compressor maintains airflow consistency to troubleshoot pressure issues effectively and safely.

Conclusion

With plasma cutting, you can achieve impressive precision and efficiency. Did you know that plasma cutters can reach temperatures up to 45,000°F, allowing them to slice through metal like it’s butter? By following this guide, you’ll guarantee a safe and effective cutting process. Always prioritize safety by wearing protective gear and maintaining your equipment. Regularly inspect consumables for wear and tear to maintain performance. With practice, you’ll master the art of plasma cutting, achieving clean, precise cuts every time.