Abrasive grit size is vital for effective metalworking. Coarse grits (40-60) are for heavy material removal, while medium grits (80-120) smooth out imperfections. For polished finishes, fine grits (220 or higher) are indispensable. When choosing grit, consider the metal’s hardness—softer metals need finer grits to avoid scratches. Gradually progressing through grit sizes minimizes damage and guarantees a high-quality finish. There’s more to discover about grit selection and sanding techniques to enhance your metalwork.

What Is Abrasive Grit Size and Why Does It Matter?

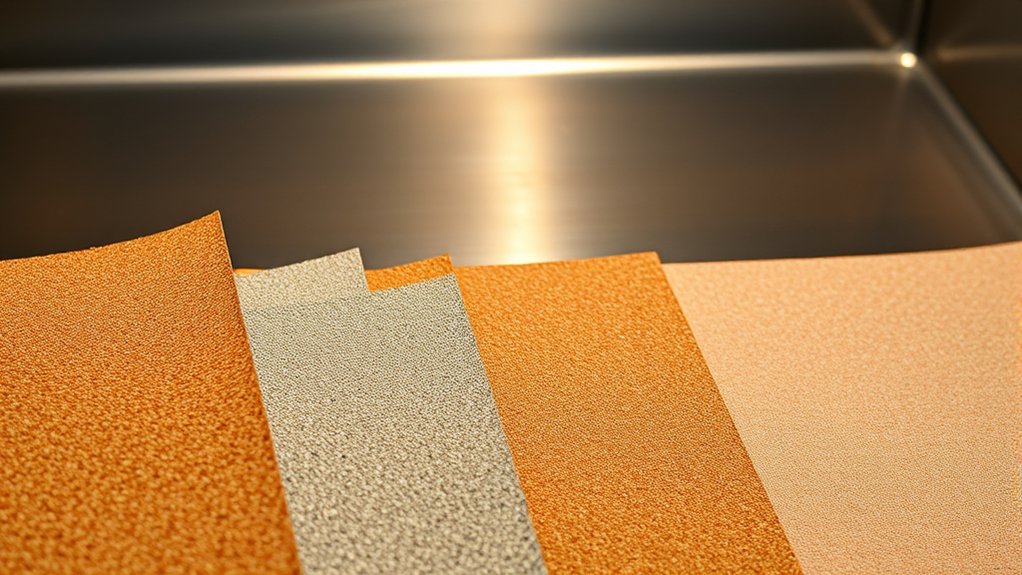

Abrasive grit size plays an essential role in the effectiveness of your metalworking projects. It indicates the size of the abrasive particles on sandpaper, where lower numbers represent coarse grits ideal for heavy material removal and higher numbers signify fine grits suitable for polishing and achieving a smooth surface finish. Coarse grits (40-60) efficiently tackle rust or paint removal, while medium grits (80-120) help in smoothing out the surface. Finally, fine grits (220 or higher) are critical for final polishing, ensuring a surface ready for paint or coatings.

Understanding grit measurement systems, like CAMI and FEPA, is key for choosing the right grit. Your choice directly impacts the surface finish quality; coarser grits can leave deeper scratches, while finer variants yield smoother surfaces. Mastering this knowledge elevates your sanding process, enhances material removal efficiency, and ultimately leads to superior results in your metalwork.

How to Choose the Right Grit for Metalworking Tasks

Choosing the right grit for metalworking tasks hinges on understanding the different grit types and matching them to your material. For heavy material removal, coarser grits are vital, while finer grits are important for achieving a polished finish. Always consider the hardness of the metal to guarantee best results throughout your sanding process.

Understanding Grit Types

Understanding grit types is essential for achieving ideal results in metalworking tasks. Choosing the right grit size can greatly impact your project’s outcome. Here’s a quick guide:

- Coarse Grits (40-60): Use these for heavy material removal, like stripping rust or paint.

- Medium Grits (80-120): Ideal for refining surfaces, they balance material removal and surface finish.

- Fine Grits (150-220): Perfect for polishing, they enhance the appearance of the metal.

Select aluminum oxide for versatility on various metals or opt for silicon carbide for tougher materials like stainless steel. Remember to clean sandpaper between grits to avoid transferring debris that can scratch surfaces, ensuring a high-quality finish throughout your sanding techniques.

Matching Grit to Material

When tackling metalworking tasks, matching the right grit to the material can greatly affect your results. Start with coarse grits (40-60) for heavy material removal on metal surfaces like rust and paint. Shift to medium grits (80-120) for smoothing, preparing the surface for finishing, and reducing visible scratches. Finally, use fine grits (150-220) for polishing to achieve a smooth surface finish ready for painting or coating. Always progress gradually through grit sizes to avoid deep scratches. Understanding metal type is essential; for instance, aluminum requires finer grits than steel to prevent damage.

| Grit Type | Grit Range | Purpose |

|---|---|---|

| Coarse Grits | 40-60 | Heavy material removal |

| Medium Grits | 80-120 | Smoothing and preparing surfaces |

| Fine Grits | 150-220 | Final polishing |

Understanding Grit Sizes: Coarse vs. Fine

Selecting the right grit size is essential for achieving the desired finish in metalwork, as each grit serves a specific purpose in the sanding process. Understanding the difference between coarse and fine grits will enhance your metalworking skills.

- Coarse Grits (40-60): Ideal for heavy material removal, these grits quickly shape and strip surfaces, effectively removing rust or paint.

- Medium Grits (80-120): Serving as an intermediate stage, they smooth rough surfaces while balancing material removal and control, prepping the area for finer sanding.

- Fine Grits (150-220): These grits refine surfaces, reducing scratches from previous stages and ensuring a smooth finish before polishing.

Common Mistakes When Selecting Grit Size for Metalwork

When selecting grit size for metalwork, you might overlook the importance of material compatibility, which can greatly impact your results. Skipping grits during the sanding process leads to visible imperfections, so always progress gradually from coarse to fine. Being aware of these common mistakes can help you achieve a smoother, more precise finish.

Ignoring Material Compatibility

Ignoring material compatibility can greatly hinder your metalworking efficiency, as each type of metal demands specific grit sizes for ideal sanding results. To achieve excellent results, consider the following:

- Grit Size Selection: Softer metals like aluminum require finer grits (120-220) to prevent scratching, while harder metals like steel can often start with coarser grits (40-80) for effective material removal.

- Abrasive Type: Choose abrasives based on the metal’s hardness; zirconia or ceramic for tough materials, and aluminum oxide for softer ones.

- Surface Finish Requirements: For a smooth finish, always opt for finer grits (220 and above) to avoid visible scratches from coarser options.

Skipping Grit Progression

Skipping grit progression can severely compromise your metalworking results, as each grit size serves a unique purpose in achieving a polished surface. Shifting too quickly from coarse grits (40-60) directly to fine grits (220+) skips essential intermediate steps, leading to deep scratches and an uneven finish. Using medium grits (80-120) after coarse grits is vital for effective material removal and blending imperfections. Each grit increment refines the surface, ensuring the proper grit is utilized for ideal surface preparation. Neglecting these steps may result in over-sanding, which alters the material’s shape and affects the final finish quality. For a seamless outcome, always adhere to grit progression to enhance your metalworking endeavors.

How Sandpaper Material Affects Grit Selection

Choosing the right sandpaper material is essential because it directly affects your grit selection and overall metalworking results. Different materials offer varying performance characteristics, impacting your sanding process. Here are three key considerations:

Selecting the appropriate sandpaper material is crucial for achieving optimal grit selection and enhancing metalworking outcomes.

- Material Type: Aluminum oxide is durable for general metal applications, while silicon carbide excels at fast material removal on harder surfaces.

- Grit Size: Use coarse grits (40-60) for heavy material removal and finer grits (220+) for polishing. Softer metals require finer grits to avoid deep scratches, whereas harder metals can handle coarser options.

- Lifespan and Efficiency: Zirconia alumina provides durability up to 220 grit, enhancing your efficiency and improving surface finish quality.

Effective Sanding Techniques for a Smooth Finish

When you aim for a smooth finish in metalwork, starting with the right sanding techniques is essential. Begin with coarse grits (40-60) for efficient material removal, tackling rust, paint, or heavy imperfections. After this initial phase, shift to medium grits (80-120) to blend any visible scratches left by coarse sanding. Finally, use fine grits (150-220) to refine the surface, ensuring a smooth finish suitable for painting or polishing.

| Grit Type | Purpose |

|---|---|

| Coarse Grit | Remove heavy imperfections |

| Medium Grit | Blend scratches and prepare surface |

| Fine Grit | Refine surface for a smooth finish |

Always clean the surface between grit changes to prevent debris from causing scratches. Remember to sand in the direction of the metal grain to achieve the best results and avoid cross-grain scratches that can mar the finish quality.

Why Does Grit Progression Matter in Metalworking?

Grit progression is important in metalworking because it directly impacts the quality of the final finish. By moving from coarse to fine grits, you minimize the depth of scratches left by earlier sanding stages, leading to a smoother surface. Here’s why grit progression matters:

Grit progression is essential in metalworking for achieving a smooth surface and high-quality finish.

- Material Removal: Coarse grits (40-60) allow for rapid removal of material, effectively stripping rust or paint.

- Surface Preparation: Medium grits (80-120) help smooth out imperfections, creating a suitable base for finer sanding.

- Final Polish: Fine grits (220 and above) are essential for achieving a polished finish, enhancing surface quality and ensuring ideal paint adhesion.

Skipping grit sizes can result in visible scratches and an uneven finish, so gradual progression is crucial. Regularly cleaning the workpiece between stages further prevents debris-induced scratches, improving overall finish quality in your metalworking projects.

How to Maintain and Care for Your Sandpaper

To guarantee peak performance and longevity of your sandpaper, it’s essential to maintain it properly throughout your metalworking projects. Regularly inspect your sandpaper for wear and replace it when the grit size is worn down or clogged. This guarantees effective sanding performance. Clean your sandpaper with a brush or compressed air between uses to remove debris, which helps extend its lifespan and ensures consistent sanding results.

Store sandpaper in a cool, dry place to prevent moisture damage, preserving the integrity of the abrasive grains. Avoid over-sanding, as excessive use can degrade both the sandpaper and the material being worked on. Always use the appropriate grit size for each stage of your project, allowing you to shift through grits to achieve the desired finish while maintaining the condition of your sandpaper. By following these steps, you’ll optimize your sandpaper’s performance and enhance the quality of your metalworking endeavors.

Frequently Asked Questions About Sandpaper Grit

Understanding the different grit sizes of sandpaper is essential for optimizing your metalworking projects. You might have questions about how to select the right abrasive for your tasks. Here are some frequently asked questions:

1. What grit size should I start with?

Begin with coarse grits (40-60) for heavy material removal, like rust or old paint.

2. When should I switch to medium grit?

Use medium grits (80-120) to smooth surfaces and blend imperfections before fine sanding.

3. How do I achieve a mirror-like finish?

Progress to fine grits (220 and above) for polishing. Finer grits (320+) are vital for that smooth finish, especially before applying protective coatings.

Frequently Asked Questions

Is 80 or 120 Grit Rougher?

80 grit is rougher than 120 grit in grit comparison. For effective surface preparation and sanding techniques, start with 80 grit for heavy material removal, then progress to 120 grit for refining before polishing methods.

How to Determine What Grit to Use?

To determine the right grit, use a grit comparison chart. Start coarse for heavy removal, progress through medium for smoothing, and finish with fine grits for polishing. Avoid common grit mistakes and follow safety precautions while sanding.

Is P400 the Same as 400 Grit?

Yes, P400 is the same as 400 grit. Both sandpaper types serve similar abrasive functions in metal finishing, surface preparation, and polishing techniques, ensuring compatibility in grit comparison, sanding methods, and grit application for ideal results.

Which Is Finer, 2000 or 3000 Grit?

In grit size comparison, 3000 grit is finer than 2000 grit. Employing a grit progression strategy guarantees ideal metalwork finishes. For automotive paint prep, selecting the right abrasive material enhances surface preparation and maintains quality with each sanding block usage.

Conclusion

In conclusion, selecting the right abrasive grit size is essential for achieving the best results in metalwork. Did you know that using a grit that’s too coarse can remove up to 50% more material than necessary, leading to wasted time and effort? By understanding grit sizes, avoiding common mistakes, and employing effective sanding techniques, you can guarantee a smoother finish and extend the life of your materials. Make informed choices, and your projects will shine with professionalism.