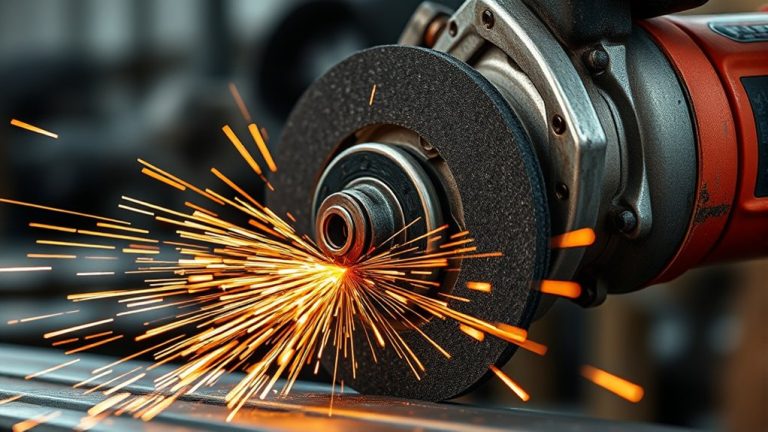

Angle grinder discs are thin, abrasive-coated materials designed for precise cutting, while grinding wheels are thicker and suited for heavy material removal. Discs function perpendicularly for accuracy, whereas wheels contact surfaces at an angle for uniformity. Flap discs combine versatility with effective rust removal on various materials. Choosing the right tool depends on your task—cutting or grinding. Learn about proper selection and safety measures to enhance your performance and project outcomes.

Understanding the Basics: What Are Angle Grinder Discs and Wheels?

Angle grinder discs and wheels are vital tools for various tasks in metalworking, woodworking, and construction. Discs are thin backing materials coated with abrasive grains, specifically designed for cutting, grinding, or polishing with handheld angle grinders. Typically, cutting discs range from 1-3 mm in thickness, allowing for precise cuts with minimal friction on diverse materials. On the other hand, grinding wheels, often referred to as wheels, are thicker, ranging from 5-7 mm, offering durability and resistance during heavy material removal. While both tools can utilize high-hardness abrasives, discs excel in tasks requiring precision, whereas grinding wheels are suited for robust applications. Understanding the structure and thickness differences between angle grinder discs and wheels is vital when selecting the right attachment for your specific projects. Making the right choice can greatly impact efficiency and quality in your work.

Key Differences: Discs vs. Wheels

While both discs and wheels serve essential functions in grinding applications, their design and purpose create distinct differences that affect their performance. Cutting discs, typically 1-3 mm thick, are used for precise cuts and operate perpendicular to the surface, focusing on high-hardness abrasives for sharpness. In contrast, grinding wheels are thicker, usually measuring 5-7 mm, and are designed for material removal and finishing tasks. They contact the surface at an angle, ensuring uniform polishing during surface preparation.

Flap discs combine features of both, offering versatility for removing rust on various materials. Discs are often coated with abrasives for specific tasks, while grinding wheels feature densely arranged abrasives and reinforcement layers for wear resistance. Understanding these key differences allows you to select the right tool for tackling hard materials effectively, ensuring excellent results in your projects.

When Should You Use a Disc or Wheel?

Choosing between a disc or wheel depends on the specific task at hand. For cutting tasks, angle grinder discs are your best choice, especially when precision is needed for materials like metal or plastic. If you’re focused on grinding and finishing, grinding wheels excel in significant material removal and provide a robust grinding action. When you require a smoother surface finish, flap discs are ideal as they continuously expose fresh grit.

Here’s a quick comparison to help you decide:

| Type | Best For |

|---|---|

| Angle Grinder Discs | Precision cutting tasks |

| Grinding Wheels | Heavy-duty material removal |

| Flap Discs | Smoother surface finishing |

| General Use | Versatile applications |

| Industrial Settings | Durability and strength |

Choosing the Perfect Disc or Wheel for Your Job

To select the perfect disc or wheel for your job, you need to contemplate the specific requirements of your task. If you’re cutting metal or stone, opt for a cut-off wheel with a thickness of 1-3 mm, made from high-hardness abrasive materials like aluminum oxide. These cutting discs are designed for precision and efficiency in removing material. For grinding tasks, however, a grinding wheel is your best bet. Thicker at 5-7 mm, these wheels focus on wear resistance and are ideal for shaping materials through friction. Verify compatibility with your power tool; cut-off wheels are suited for angle grinders, while grinding wheels are primarily used with traditional grinders. By choosing the right grinding tools, you’ll enhance your finishing work and achieve better results in your projects.

Safety Tips for Using Angle Grinder Discs and Wheels

Using an angle grinder can be highly effective for various tasks, but safety should always be your top priority. Always wear appropriate personal protective equipment, including safety goggles, gloves, and hearing protection, to shield yourself from flying debris and excessive noise. Before starting, inspect discs and wheels for any signs of wear and damage; compromised tools can shatter during operation. Verify you’re using the correct disc or wheel for your specific task, as using the wrong type can lead to accidents and increased wear on the tool.

Maintain a firm grip on the angle grinder, using both hands if possible, to prevent kickback, which may occur if the disc catches on the material. Finally, always adhere to the manufacturer’s guidelines for maximum RPM ratings and usage instructions to avoid overheating and guarantee safe operation. Prioritizing these safety measures will empower you to work confidently and effectively.

Frequently Asked Questions

What Is the Difference Between a Grinding Wheel and a Grinding Disc?

A grinding wheel’s thicker materials offer greater durability, while a disc’s thinner design allows for versatile grit types. You’ll find the wheel’s arbor size essential for heavy tasks, while discs excel in safety and performance ratings.

What Does Type 27 Mean on a Grinding Wheel?

Type 27 on a grinding wheel signifies a flat disc design with a recessed center, enhancing compatibility for various materials. It excels in applications like weld grinding, offering superior performance and versatility for finishing tasks.

What Are Three Different Types of Angle Grinder Discs?

To hit the ground running, you’ll find three main types of angle grinder discs: cutting discs for precise cuts, flap discs for grinding and finishing, and diamond blades for tough materials like concrete.

What Is a Grinding Wheel Called?

A grinding wheel’s called a molded abrasive tool, featuring various types, materials, sizes, and grit levels. You should consider shape classifications and application methods while prioritizing safety tips and maintenance practices for ideal performance.

Conclusion

In conclusion, understanding the distinction between angle grinder discs and wheels is like knowing the difference between a scalpel and a hammer; each serves its purpose in specific tasks. By choosing the right disc or wheel for your project, you’ll enhance efficiency and safety. Always prioritize safety precautions while using these tools to guarantee a smooth, successful operation. Now that you’re equipped with this knowledge, you can tackle your grinding tasks with confidence and precision.