An angle grinder flap disc is a versatile tool for grinding and finishing metal surfaces, featuring overlapping flaps of abrasive material. You’ll need to choose the right grit size: coarse (36-40) for heavy removal, medium (40-60) for weld blending, and finer (80-120) for a smooth finish. Pay attention to disc shape as well—flat or conical—to maximize effectiveness. Proper technique and material selection are essential for best results, and there’s more to explore about achieving superior finishes.

Understanding Flap Discs: What They Are and How They Work

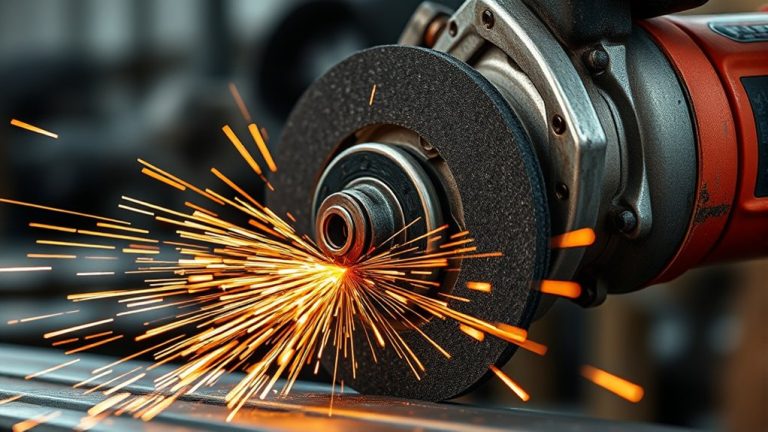

Flap discs are essential tools in metalworking, combining versatility with efficiency. These innovative abrasive tools consist of overlapping flaps made from coated abrasive material, designed specifically for grinding, blending, and finishing metal surfaces. Unlike traditional grinding wheels, flap discs adapt to surface contours, ensuring uniform wear and effective material removal. You’ll find two main shapes: Type 27, which is flat for shallow angles, and Type 29, conical for aggressive stock removal. The performance of flap discs largely depends on the abrasive material used—options like zirconia alumina and aluminum oxide offer distinct advantages for varying applications. Grit size is another critical factor; lower grit numbers are ideal for heavy stock removal, while higher numbers are perfect for finishing and smoothing tasks. Understanding these elements will empower you to choose the right flap disc for your metalworking projects, enhancing your efficiency and results.

How to Pick the Perfect Grit for Your Flap Disc Project

How do you guarantee ideal results in your metalworking projects? Selecting the right grit size for your standard-density flap discs is essential. Here’s how to choose:

Selecting the right grit size for flap discs is crucial for achieving ideal results in metalworking projects.

- Coarse Grit (36-40): Best for heavy material removal; may leave deeper scratches.

- Medium Grit (40-60): Great for weld grinding and blending; balances material removal and finish quality.

- Finer Grit (80-120): Perfect for cleaning and finishing applications; provides a smooth surface for painting or coating.

- Transitioning: Move from coarse to finer grit for best results, enhancing both material removal and finish quality.

Always consider the material type and desired finish when selecting grit size. Different materials may require specific grit selections to achieve the finest outcome with your angle grinder. Making informed choices guarantees your projects stand out, reflecting both precision and craftsmanship.

Flat vs. Conical Flap Discs: Why Shape Matters

Selecting the right grit is only part of achieving excellent results in your metalworking projects; the shape of your flap disc plays a significant role too. Flat flap discs (Type 27) are perfect for shallow angles (0-15 degrees), providing smooth surface finishes on flat surfaces. They excel in detail work where precision is key. On the other hand, conical flap discs (Type 29) are designed for steeper angles (15-35 degrees), maximizing surface contact for aggressive stock removal and enhanced material removal efficiency. The conical shape allows for better flap-to-metal contact, making them ideal for tasks requiring high grinding efficiency. Specialty shapes, like mini and trimmable discs, offer flexibility in tight spaces or hard-to-reach areas. Choosing between flat and conical flap discs is essential for achieving peak performance and the desired surface finishes in your projects. Understanding these differences will empower your metalworking endeavors.

Selecting the Best Abrasive Material for Your Flap Discs

When it comes to achieving ideal performance in metalworking, the right abrasive material for your flap discs can greatly influence both efficiency and longevity. Selecting the right abrasive material is essential for optimizing your grinding process. Here are key options to evaluate:

- Aluminum Oxide: Cost-effective for general use, great for softer metals, but less effective on harder materials.

- Zirconia Alumina: Versatile and durable, self-sharpening, perfect for aggressive stock removal.

- Ceramic Alumina: Best for heavy-duty applications, maintains cooler temperatures to prevent overheating during use.

- Application-Specific Selection: Assess the environment; ceramic and zirconia are preferable for industrial settings requiring high performance and durability.

Best Practices for Achieving a Smooth Finish With Flap Discs

To achieve a smooth finish with flap discs, start by selecting the right grit size; begin with a coarser grit for initial stock removal and follow up with a finer grit for finishing. Utilize ideal grinding techniques, applying steady and moderate pressure to maintain control and prevent gouging. Regularly inspect your discs to guarantee they remain effective, as worn abrasives can compromise the quality of your work.

Selecting Appropriate Grit Size

Achieving a smooth finish with flap discs hinges on choosing the right grit size, as it directly influences the quality of your workpiece. Here’s a breakdown to guide your selection:

- Coarser grits (36-40) are best for heavy stock removal, leaving deeper scratch patterns.

- For weld grinding, a medium grit size (40-60) balances material removal and finishing quality.

- Finer grits (80-120) excel in achieving smooth finishes for delicate applications.

- Transitioning from coarser to finer grits enhances aesthetic outcomes, especially before painting.

Don’t forget to invest time in testing different grits on scrap material. This guarantees you achieve the desired scratch pattern and finishing quality, tailoring your approach to specific project needs.

Optimal Grinding Technique

While using flap discs, maintaining an ideal grinding technique is essential for achieving a smooth finish on your workpiece. Aim for a consistent angle between 5 to 35 degrees for peak contact with the surface. Apply moderate pressure during grinding to guarantee effective material removal without overheating or excessive wear on the flap disc. Start with coarser grits (36-60) for initial stock removal and shift to finer grits (80-120) for finishing, enhancing the performance quality of the surface. Keep the flap disc moving in a controlled manner to prevent deep scratch patterns that could necessitate additional finishing work. Regularly inspect the flap disc for wear and replace it when glue becomes visible for consistent results.

Avoid These Common Mistakes When Using Flap Discs

How can you guarantee ideal performance and safety when using flap discs? Avoiding common mistakes is key. Here are some pitfalls to steer clear of:

- Wrong grit size: Use coarser grits (36-40) for heavy stock removal and finer grits (80-120) for finishing.

- Neglecting wear and damage: Always inspect flap discs for visible degradation or glue exposure before use.

- Excessive pressure: Apply moderate pressure during grinding to prevent premature wear and gouging of the workpiece.

- Incorrect grinding angle: Maintain a grinding angle between 5 to 35 degrees for peak performance and even wear.

Frequently Asked Questions

Can I Use Flap Discs on Materials Other Than Metal?

Yes, you can use flap discs on wood surfaces, plastic materials, and for concrete grinding. They’re effective for stone polishing, fiberglass applications, automotive bodywork, ceramic tiles, glass edges, composite materials, and drywall sanding too.

How Long Do Flap Discs Typically Last With Regular Use?

Flap discs typically last several hours with regular use, but your technique, material type, and grinding speed affect their lifespan. Watch for wear indicators and replacement signs to maintain application efficiency and avoid excessive heat generation.

Is It Safe to Use Flap Discs Without Protective Gear?

It’s not safe to use flap discs without protective gear. Prioritize safety measures like eye protection, respiratory protection, and hearing protection. Conduct a risk assessment, practice proper handling, and guarantee gear maintenance for effective injury prevention.

Can Flap Discs Be Used on Curved Surfaces Effectively?

Yes, flap discs can effectively contour curved surfaces. By mastering grinding techniques and understanding material flexibility, you’ll achieve excellent finishing results. Consider tool compatibility and application methods to optimize performance factors during your projects.

How Do I Store Flap Discs to Prolong Their Lifespan?

To prolong your flap disc’s lifespan, store them in organized storage under ideal conditions. Guarantee moisture control, temperature regulation, and use protective coverings to enhance shelf life, especially with frequent usage and impact resistance considerations.

Conclusion

To conclude, mastering flap discs can greatly enhance your grinding and finishing projects. Did you know that using the correct grit can improve material removal rates by up to 30%? By selecting the right shape, abrasive material, and following best practices, you’ll achieve a smoother finish and increase efficiency. Avoiding common mistakes is key to maximizing your results. With this knowledge, you’re well-equipped to tackle any job with confidence and precision.