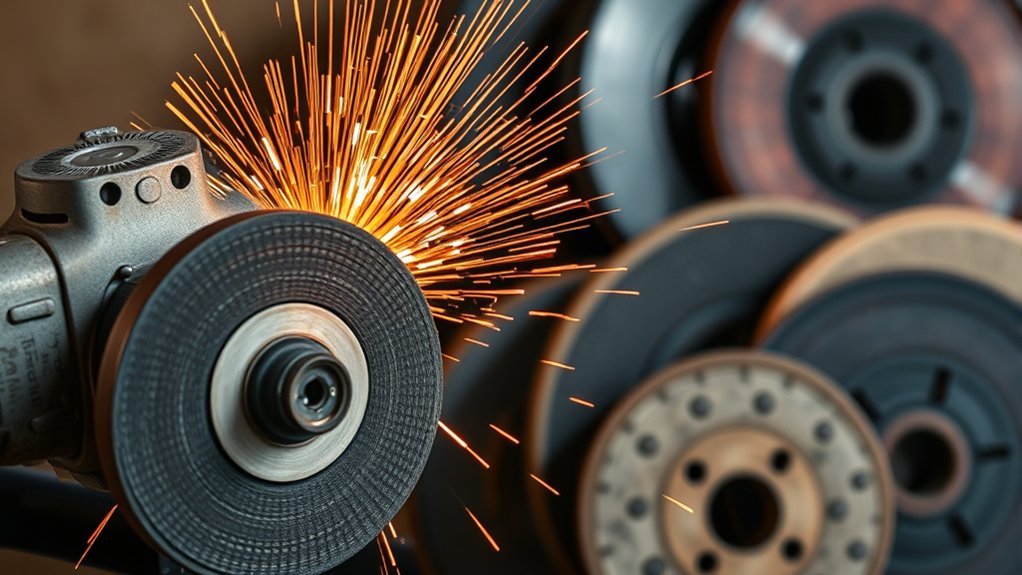

Angle grinder wheels come in several types, including grinding wheels, cut-off discs, flap discs, wire wheels, and diamond cutting discs, each suited for specific tasks like grinding, cutting, and surface preparation. Grinding wheels focus on material removal, while cut-off discs provide precise cuts. Always choose the right wheel based on the material and application, ensuring compatibility with your grinder’s specifications. For best practices and safety tips, explore further details on maintaining and selecting wheels effectively.

Angle Grinder Wheels: Types and Uses

When working with an angle grinder, you’ll encounter several types of wheels, each designed for specific tasks. The primary angle grinder discs include grinding wheels, cut-off discs, and flap discs. Grinding wheels excel in material removal, available in varying grits; lower grits remove material quickly, while higher grits deliver smoother finishes. Cut-off discs, thinner than grinding wheels, are perfect for precise cuts on metal bars and sheets but require careful handling to prevent shattering. Flap discs function similarly to sandpaper, ideal for finishing tasks, smoothing surfaces, and removing burrs, making them versatile for metal repair. When selecting the right angle grinder wheel, consider the diameter and thickness, as these factors influence usability, performance, and safety, particularly in relation to your tool’s RPM rating. Understanding these types of angle grinder wheels empowers you to choose effectively for your specific project needs.

Key Differences Between Grinding Discs and Cut-off Wheels

When using an angle grinder, it’s essential to understand the distinct roles of grinding discs and cut-off wheels. Grinding discs are thicker and designed for material removal, while cut-off wheels are thinner, tailored for precise cutting tasks. This difference in thickness and functionality impacts not only the performance but also the safety considerations during use.

Purpose And Functionality

Understanding the key differences between grinding discs and cut-off wheels is essential for selecting the right tool for your project. Grinding discs are ideal for material removal and surface preparation, featuring a coarser grit for aggressive grinding. In contrast, cut-off wheels are thinner, designed for precise cutting through metal workpieces.

| Feature | Grinding Discs | Cut-off Wheels |

|---|---|---|

| Design | Thicker for durability | Thinner for cutting efficiency |

| Grit Size | Coarser for rapid removal | Finer for clean cuts |

| Common Use | Shaping, smoothing, grinding | Cutting metal bars and bolts |

Both require proper safety gear, as grinding discs create sparks, while cut-off wheels risk shattering. Choosing wisely enhances your project’s success.

Thickness And Design Differences

While selecting the right tool for your project, it’s important to recognize that thickness and design differences greatly influence the performance of grinding discs and cut-off wheels. Grinding discs are typically thicker, around 1/4 inch, and engineered for aggressive material removal, making them ideal for shaping and smoothing surfaces. In contrast, cut-off wheels are thinner, usually 1/8 inch, optimized for precise, clean cuts. The robust design of grinding discs can handle intense grinding stresses, whereas cut-off wheels feature a tapered edge for efficient penetration. It’s vital to match the tool to the task; using a grinding disc for cutting can lead to inefficiency, while using a cut-off wheel for grinding can result in damage and safety hazards.

How Wire Wheels Improve Surface Preparation

Wire wheels are vital tools for effective surface preparation, specifically designed to remove rust, paint, and debris from metal surfaces. Constructed from metal wire strands, they come in various shapes and bristle thicknesses, providing flexibility for different applications based on surface condition and material type. Their abrasive quality allows wire wheels to prepare surfaces without greatly altering the underlying material, making them ideal for delicate tasks.

However, safety can’t be overlooked. Always wear personal protective equipment (PPE) when using wire wheels, as there’s a risk of wire strands breaking off and becoming hazardous projectiles. It’s also important to choose high-quality wire wheels; lower-quality options may degrade quickly and increase safety risks due to potential breakage during operation. Prioritizing quality and safety guarantees you achieve the best surface preparation without compromising your well-being.

When Should You Use Flap Discs?

When should you reach for flap discs instead of traditional grinding wheels? If you’re looking to achieve a smoother finish in your metalworking projects, flap discs are your go-to choice. Their layered design allows for effective polishing and finishing tasks, which traditional grinding wheels can’t provide. Here’s when you should use flap discs:

Flap discs excel in achieving smoother finishes and effective polishing, making them ideal for metalworking projects.

- For removing burrs and chamfering edges

- When smoothing heavily ground surfaces

- To achieve various surface finishes by selecting different grit levels

- On materials like steel, stainless steel, and aluminum

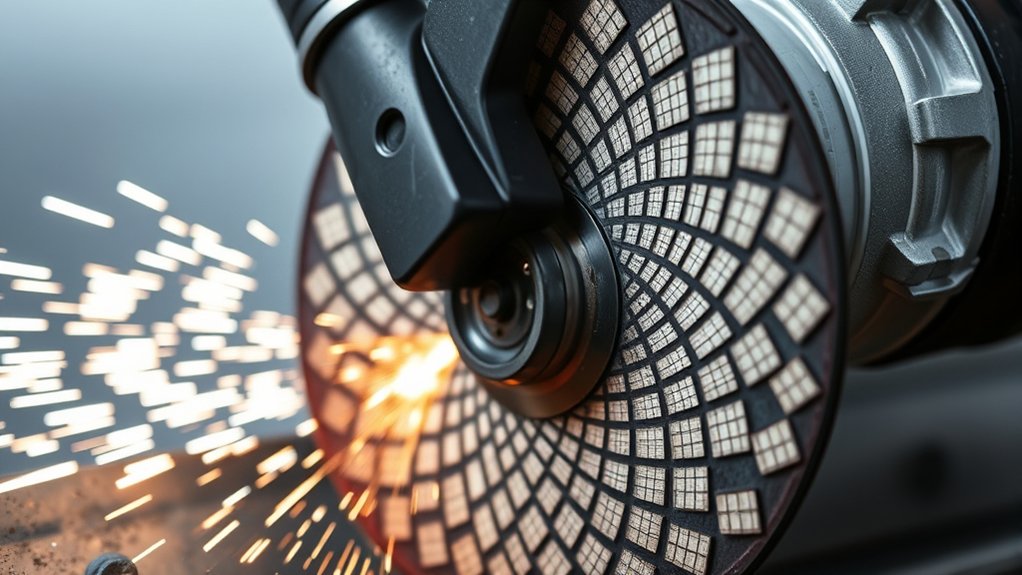

Diamond Cutting Discs: Key Angle Grinder Wheels for Precision

Diamond cutting discs are essential for precision work on hard materials like granite and concrete. You’ll find that using the right cutting techniques enhances performance and prolongs the life of the disc. Let’s explore the ideal applications for diamond discs and key tips for effective cutting.

Ideal Applications for Diamonds

For precision cutting in construction and renovation, diamond cutting discs are unmatched tools. Engineered with abrasive diamond shards, these discs excel at cutting hard materials like granite, concrete, and masonry. Here are some ideal applications for diamond cutting discs:

- Granite countertops: Achieve clean edges for a professional finish.

- Concrete slabs: Cut through thick material efficiently, minimizing heat.

- Masonry projects: Perfect for precise cuts in brick or stone.

- Tile installation: Guarantee accurate, smooth cuts for seamless layouts.

When selecting a disc, remember to match its specifications with your angle grinder’s RPM rating to assure peak performance and safety. With the right diamond cutting disc, you’ll master precision cutting like never before.

Cutting Techniques and Tips

Achieving ideal results with diamond cutting discs requires understanding specific cutting techniques and tips that enhance performance. These sharp angle grinder wheels excel at cutting hard materials like concrete and granite. Maintain best cutting angles between 0 to 15 degrees to maximize efficiency and reduce wear on your diamond cutting discs. Apply consistent pressure without forcing the tool; let the diamond disc do its job while you maintain control for clean, precise cuts. Verify your angle grinder is compatible with the disc’s diameter and thickness to avoid operational hazards. By following these practices, you’ll elevate your results and make the most of your cutting wheels, transforming challenging tasks into manageable projects.

Polishing Pads: Achieving a Perfect Finish

While you’re seeking a flawless finish on metal or other surfaces, polishing pads serve as an essential tool in your angle grinder arsenal. These pads are designed to smooth out imperfections effectively while minimizing material removal. For peak performance, verify your angle grinder has speed control features to prevent overheating.

- Choose from materials like foam, wool, and microfiber tailored for specific tasks.

- Work at lower speeds and apply light pressure to protect the surface being polished.

- Regularly inspect and replace your polishing pads to maintain their effectiveness.

- Keep an eye out for any scratches or imperfections that could transfer to your workpiece.

Safety Tips for Using Angle Grinder Wheels

Polishing pads enhance the finish on various surfaces, but safety shouldn’t be overlooked when using angle grinder wheels. Always wear appropriate personal protective equipment (PPE) like safety goggles, gloves, and dust masks to shield yourself from flying debris and dust. Before changing any wheels, verify the angle grinder is turned off and unplugged to prevent accidental activation.

Inspect the grinding wheel for any signs of damage or wear, such as cracks or chips; damaged wheels can shatter during operation, creating serious hazards. Maintain a firm grip on the grinder and use both hands, especially with larger models, to enhance control and reduce the risk of kickback. Finally, always adhere to the manufacturer’s guidelines regarding the correct wheel size and type for your specific angle grinder model. Prioritizing these safety tips will empower you to work confidently and efficiently.

Selecting the Right Angle Grinder Wheel for Your Project

Selecting the right angle grinder wheel is essential to achieving the best results in your project, as each wheel serves specific purposes tailored to different materials and tasks. When choosing your grinding wheels, consider the following factors:

Choosing the correct angle grinder wheel is crucial for optimal results in your projects, tailored to specific materials and tasks.

- Material Type: Different wheels are designed for specific materials like metal, wood, or masonry.

- Grit Size: Lower grit numbers (24-60) are for quick material removal, while higher grit numbers (80-120) offer smoother finishes.

- Diameter Compatibility: Confirm the wheel diameter matches your angle grinder’s specifications to avoid safety hazards.

- Wheel Angle: Type 27 wheels are ideal for shallow angles (25-30 degrees) for aggressive grinding, while type 28 wheels work best in confined spaces at 0-15 degrees.

Always verify the RPM rating of the wheel against your grinder’s RPM to ascertain compatibility. Selecting the right wheel is pivotal for efficient and safe operation.

Frequently Asked Questions

What Are the Different Types of Angle Grinder Wheels?

You’ve got several types of angle grinder wheels to choose from: grinding discs, cut-off discs, and flap discs. For peak performance, consider grinding wheel materials and wheel size selection, and always wear safety gear for protection.

What Does Type 27 Mean on a Grinding Wheel?

Type 27 on a grinding wheel refers to its flat, depressed center design, optimizing grinding wheel specifications for aggressive cuts. It meets wheel safety standards, making it ideal for various angle grinder applications, ensuring effective and secure use.

What Is the Difference Between Type 1 and Type 27 Cutting Wheels?

Type 1 cutting wheels are straight and thinner, ideal for aggressive metal removal, while Type 27 wheels have a flat, depressed center, enhancing stability and access for general grinding tasks using various wheel materials.

What Is a Type 42 Grinding Wheel?

A Type 42 grinding wheel excels in surface grinding, using durable materials like aluminum oxide or silicon carbide. Its advantages include efficient material removal and versatility for applications like weld grinding, ensuring smooth, precise finishes.

Conclusion

In conclusion, choosing the right angle grinder wheel is vital for your project’s success. With various types available—each designed for specific tasks—it’s imperative to match them with your needs. So, which wheel will you pick to achieve the best results? Remember to prioritize safety and best practices to guarantee both efficiency and protection while you work. Armed with this knowledge, you’re ready to tackle your grinding tasks with confidence and precision!