An angle grinder is a compact, powerful handheld tool used for cutting, grinding, blending, and cleaning metal and masonry. This guide explains how angle grinders work, which size and features to choose, how to mount and use different wheels, and the safety steps that prevent injuries and costly mistakes. It’s written for hobbyists, metal fabricators, welders, and anyone who wants to use an angle grinder with confidence.

🔧 Which angle grinder size, power, and switch type is best?

Size and wheel diameter

Angle grinders are commonly identified by the wheel diameter. The most popular size for general shop work is 4.5 inches (115mm). Larger wheels exist (5″, 6″, 7″, 9″) and offer faster removal and deeper cuts, but they add weight and require more power and different guards.

Motor power (amperage)

Amperage correlates to motor torque and how well the grinder holds speed under load. Typical corded hobbyist grinders run from about 7 to 11 amps. For most workshop cutting, grinding, and weld prep tasks, an 8 to 9 amp grinder is sufficient. Choose a higher-amp model (11-13 amps) if you expect heavy-duty, long-duration metal removal to prevent the motor from bogging down.

Switch types

There are three main switch styles to consider:

- Slide switch — simple on/off lock; convenient for long grinding sessions but can be dangerous if the tool is dropped, as it stays on.

- Paddle trigger — runs only while squeezed (dead-man switch); safer because it stops immediately when released.

- Trigger grip (rear handle) — common on larger grinders; feels like a drill handle and also stops when released.

🧰 How to mount angle grinder wheels correctly

There are three common wheel mounting styles to learn and inspect before every use:

- Threaded insert — wheels or cup brushes with a threaded bushing screw straight onto the spindle (usually 5/8″-11 thread in North America).

- Through-hole + nut (Standard 7/8″ Arbor) — wheels with a plain center hole are secured with a locking nut. Critical Safety Rule: The nut has two sides. Use the flat side against thin cutoff wheels. Use the stepped (shouldered) side down into the hole for thicker grinding wheels (1/8″ or thicker).

- X-LOCK and Rapid Change — modern grinders may use tool-free “click-on” systems (X-LOCK) or tool-free nuts. Ensure your wheels match your specific grinder mount type.

Step-by-step mounting checklist:

- Unplug or remove battery before changing wheels.

- Check the wheel center hole for fit and the spindle thread direction.

- Use the correct nut orientation: Flat side for thin cutting discs, shouldered side for thick grinding discs.

- Tighten the nut securely with a wrench, but avoid over-torquing which can crack the disc hub.

- Verify the wheel rotates freely and the guard does not contact the disc.

🪓 Wheel types and when to use them

Choosing the right disc for the task improves performance and safety. Below are the most common wheel types for metalwork.

Cutoff wheels (abrasive type 1 or type 27)

Thin abrasive cutoff discs (often 0.040″ or 0.045″ thick) are designed to slice through metal with minimal material removal. They are inexpensive and fast at cutting. Important points:

- Never use cutoff discs for side grinding. They are reinforced only on the face and will shatter if side pressure is applied.

- Watch the wheel RPM rating and ensure it exceeds the grinder’s no-load speed (usually 10,000–12,000 RPM for 4.5″ grinders).

- Keep cuts light and straight; let the disc do the work without forcing it.

Diamond cutoff wheels (for metal)

Diamond-edge metal cutoff blades maintain their diameter (they don’t shrink like abrasives) and produce cleaner cuts. They are safer against breakage but often cut slower and have a higher upfront cost.

Grinding wheels (solid abrasive)

Hard grinding wheels (usually 1/4″ thick) are for heavy material removal, shaping, and removing mill scale. Use the wheel face at a 30 to 45-degree angle. These are robust enough for heavy pressure.

Flap discs (flap wheels)

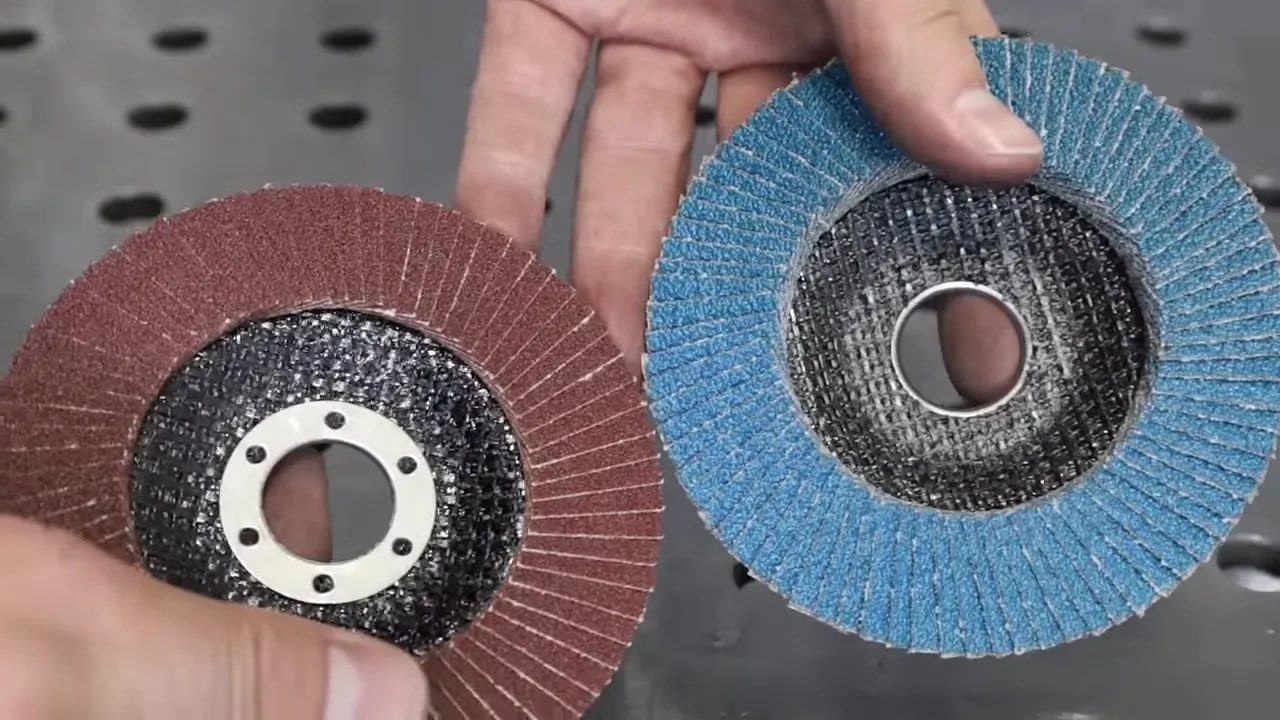

Flap discs are made from layered abrasive sandpaper flaps. They grind and finish in one step, making them great for blending welds and smoothing surfaces without gouging the metal like a hard wheel might.

- Zirconia vs. Aluminum Oxide: Choose Zirconia (often blue or green) for steel and stainless steel; it lasts longer and cuts faster than standard aluminum oxide (brown).

- Conical (Type 29) vs. Flat (Type 27): Use conical for aggressive stock removal at an angle; use flat for blending and finishing on flat surfaces.

Wire brushes (cup and twisted/stringer)

Wire cup brushes clean large flat surfaces quickly, while twisted (knot) wheels are designed for aggressive cleaning in grooves or welds. Warning: Wire wheels frequently throw loose wires. Eye and body protection is mandatory.

🛠️ Correct cutting technique — step-by-step

Using the right technique reduces kickback risk, keeps the disc cooler, and extends wheel life.

- Secure the work. Clamp the part firmly. If the wheel binds in a loose part, the grinder will kick back violently.

- Fit the guard and handle. The guard should be positioned between you and the cut to deflect sparks and debris away. Use the side handle for a two-handed grip.

- Check wheel speed rating. Confirm the wheel’s maximum RPM is higher than the grinder’s sticker RPM.

- Watch your spark stream. Orient the tool so sparks fly away from your body and away from flammable materials.

- Cut with the rotation (pull vs. push). Generally, hold the grinder so the wheel pulls the tool forward slightly. This reduces the chance of the wheel climbing out of the cut and kicking back at you.

- Let the disc do the cutting. Do not force or twist the wheel in the cut. Forcing it creates heat, glazes the abrasive, and increases the risk of shattering.

⚙️ Grinding and weld preparation best practices

Use the right wheel, angle, and pressure to shape metal and prepare for welding:

- Grinding angle — 30 to 45 degrees for hard grinding wheels. Too flat, and you risk eroding the retaining nut; too steep, and you gouge the metal.

- Flap discs for finish — finer-grit flap discs (80-120 grit) provide a paint-ready surface.

- Heat control — keep the wheel moving. Stopping in one spot creates “hot spots” that can harden the metal or cause warping.

- Grit selection — start coarse (40–60 grit) for heavy removal and switch to finer grits for blending.

🛡️ Safety checklist (do these every time)

- Guard in place — never remove the guard. It is the only thing between you and a shattered disc spinning at 11,000 RPM.

- Two-handed grip — attach the side handle and keep both hands on the tool to control kickback.

- PPE — Safety glasses are not enough. Wear a face shield over glasses. Use hearing protection (grinders are loud, 90-100dB), a respirator for dust, and flame-resistant gloves.

- Wheel inspection — discard cracked, chipped, or wet-affected wheels. Check the expiration date stamped on the metal center ring (resin bonds degrade over time).

- Speed rating — ensure wheel RPM rating > grinder RPM.

- Workpiece secured — clamp the part; do not hold small pieces in your hand.

- Clear area of flammables — sparks can fly 20+ feet. Remove gas cans, oily rags, and sawdust from the area.

- Unplug to change wheels — never change a wheel while the tool is plugged in or the battery is attached.

⚠️ Common mistakes and how to avoid them

- Using a cutoff wheel for side grinding — This is the #1 cause of wheel failure. Cutoff wheels are for edges only.

- Mounting the nut backward — Remember: Flat side of the nut against thin wheels; shouldered side against thick wheels. Getting this wrong causes the wheel to wobble or crack.

- Putting oversized wheels on a small grinder — Removing a guard to fit a 5″ wheel on a 4.5″ grinder is extremely dangerous and changes the speed dynamics.

- Not clamping the work — an unclamped piece will spin or move and cause the wheel to bind/kickback.

- Breathing grinding dust — Metal and abrasive dust is hazardous. Wear a mask.

🧾 Quick maintenance and accessory checklist

- Spares: cutoff wheels, flap discs (40 & 80 grit), grinding wheels

- Pin wrench (spanner) or quick-nut for your grinder

- C-Clamps or Locking Pliers

- Cutting Guard: A specialized “Type 1” guard that covers both sides of the wheel is recommended for cutting operations.

- PPE: Face shield, earplugs, N95 respirator

📌 Practical examples and short workflows

Cutting a 16-gauge steel sheet

- Clamp the sheet to a workbench with the cut area fully supported (or hanging freely so the cut opens up, not pinches closed).

- Install a 1/16″ abrasive cutoff wheel. Ensure the nut is flat-side down.

- Attach guard and handle, wear PPE.

- Make a light scoring pass first to establish the line.

- Follow with steady pressure to slice through. Do not twist the tool.

- Deburr the sharp edge with a flap disc.

Removing mill scale before welding

- Use a coarse (40 or 60 grit) flap disc or a grinding wheel.

- Hold at a shallow angle (15-30 degrees for flap discs).

- Move constantly to strip the grey scale until you see bright, shiny silver metal.

- Clean at least 1 inch back from the weld joint.

❓ FAQ

What disc should I use to cut metal quickly?

A thin abrasive cutoff wheel (0.045″) cuts fastest and generates the least heat. Ensure you use a cutting guard when using these wheels.

Can I use a cutoff wheel to grind on the side?

Absolutely not. Cutoff wheels are thin and lack the fiberglass reinforcement layers needed to withstand side pressure. They can explode if used for grinding. Use a grinding wheel or flap disc instead.

How do I check if a wheel is safe to use?

Visually inspect for cracks, chips, or fraying edges. Check the “Use By” date stamped on the center ring. If a wheel has been dropped or soaked in water, discard it. Do not use the “ring test” on resin-bonded angle grinder wheels; that is for bench grinder stones.

What PPE is essential for angle grinding?

The “Big Three”: Face shield (over safety glasses), hearing protection, and gloves. A dust mask is highly recommended, and a leather apron helps prevent burns from sparks.

Is a cordless angle grinder a good alternative?

Yes. Modern high-voltage (18V/60V) brushless cordless grinders offer power comparable to corded units. However, grinding consumes batteries very quickly. For all-day grinding, a corded tool is often more efficient. For quick field cuts, cordless is superior.

✔️ Final takeaways

An angle grinder is the workhorse of any metal shop, but it demands respect. Focus on matching the correct wheel to your task (cutting vs. grinding), ensuring the locking nut is oriented correctly, and never skipping the guard. With proper technique and safety gear, you can cut, shape, and polish metal efficiently and safely.

Always inspect your discs before mounting—a damaged wheel is the most common cause of accidents. Stay safe and keep the sparks flying away from you.