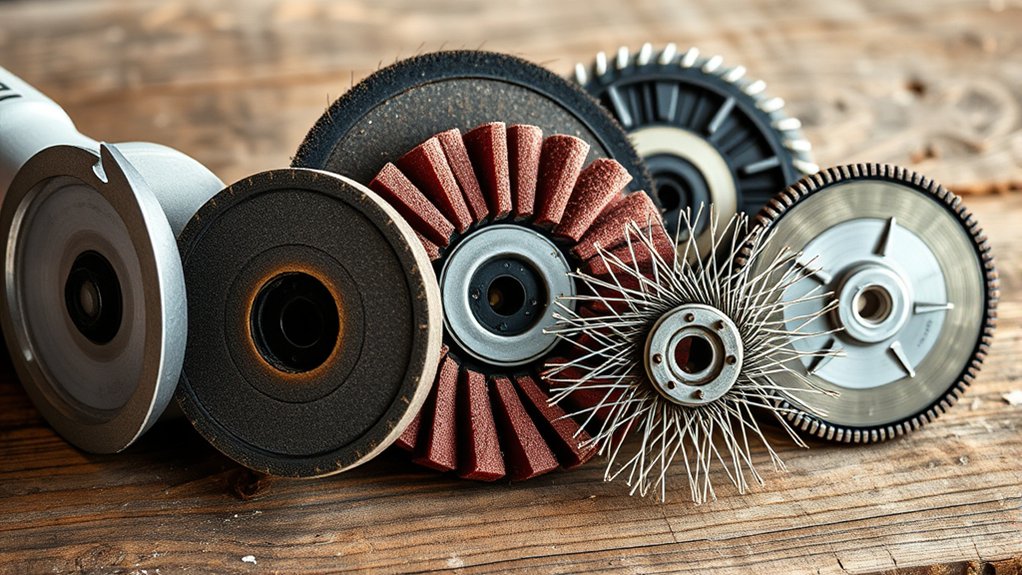

Angle grinder wheels come in several types, each serving a specific function. Grinding discs are used for material removal, while cut-off discs excel in precise metal cuts. Flap discs provide a smooth finish, combining grinding and finishing capabilities. Wire wheels efficiently remove rust and paint, and diamond discs are perfect for cutting tough materials like stone. Knowing the right type for your project is essential. Keep exploring to discover more about their unique applications and benefits.

Get to Know Angle Grinder Wheels: Types and Their Uses

When you’re working with an angle grinder, understanding the different wheel types is crucial for achieving the best results. Angle grinder wheels vary considerably, each designed for specific tasks. Grinding discs are the most common, perfect for material removal on metal surfaces, available in various grit levels to suit your needs. Cut-off discs, thinner and more precise, allow you to slice through metal bars and sheets, but handle them carefully to avoid shattering. For finishing tasks, flap discs shine, using overlapping abrasive sheets that continually expose fresh grit as they wear down. If rust removal is your goal, wire wheels efficiently remove rust and paint, although be cautious of flying wires. Finally, diamond discs are your go-to for cutting hard materials, offering durability and precision. Choosing the right wheel guarantees your project runs smoothly and effectively.

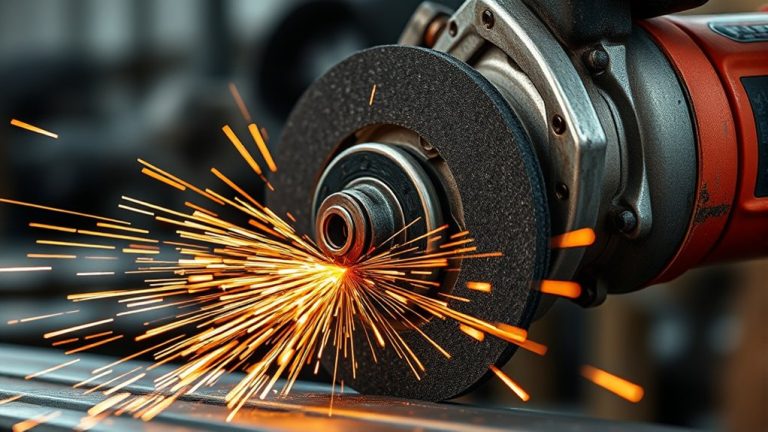

Why Grinding Wheels Are Essential for Angle Grinder Use

While you may be tempted to overlook the importance of grinding wheels, they are essential tools for maximizing the efficiency of an angle grinder. Designed specifically for cutting and shaping metal, grinding wheels enable you to efficiently remove excess material, making them indispensable for fabrication and preparation tasks. Their versatility allows for various applications, from smoothing welds to grinding rough edges.

| Coarseness Level | Application |

|---|---|

| Low Grit | Fast material removal |

| Medium Grit | General grinding |

| High Grit | Smoother finishes |

| Extra Fine Grit | Final polishing |

With a range of coarseness available, you can select the right wheel for your needs, enhancing your workflow and productivity. Regular use of grinding wheels also extends the longevity of your tools, ensuring that you achieve ideal metal surface preparation and reduce wear during subsequent operations.

The Essential Uses of Cut-Off Wheels for Angle Grinders

Grinding wheels play a significant role in a variety of tasks, but cut-off wheels are specifically tailored for precise cutting applications. Designed with a thin profile, these wheels enable quick and clean cuts in materials like metal bars, sheets, and tubes. You’ll find cut-off wheels in various thicknesses; thinner options deliver faster cuts but may exhibit brittleness, increasing the risk of shattering. For cutting tougher metals, thicker wheels offer better stability and reduce breakage likelihood during operation.

When utilizing cut-off wheels with your angle grinder, always wear appropriate safety gear to protect against flying debris and potential wheel failure. These wheels excel in various applications, such as shortening bolts, cutting out welds, or making precise cuts in metal stock while minimizing unnecessary material removal. By understanding their uses and limitations, you can maximize your efficiency and safety in every project.

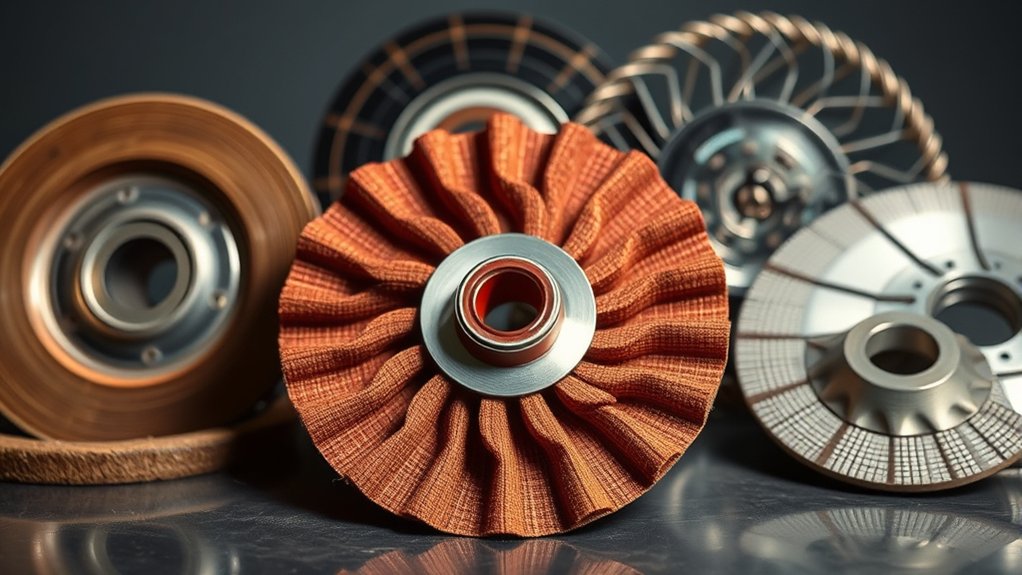

Flap Discs: The Finishing Touch for Metalwork

Flap discs offer a unique advantage in metalworking by combining the benefits of both grinding and finishing tools. With their overlapping abrasive sheets, these discs continuously expose new grit as they wear, making them ideal for achieving a finer finish on metal surfaces. Here are four key benefits of using flap discs:

Flap discs uniquely blend grinding and finishing capabilities, ensuring a fine metal surface finish with every use.

- Versatile Grit Levels: Choose the right disc for surface finishing or light material removal.

- Enhanced Precision: Effectively remove metal burrs and sharp corners for precise metalwork.

- Smoother Finish: Unlike traditional grinding wheels, flap discs provide a polished surface after initial grinding.

- Durable for Hard Metals: Ideal for renovation and repair tasks in metal fabrication.

Incorporating flap discs into your workflow not only elevates the quality of your work but also streamlines the finishing process, ensuring you achieve the desired results with efficiency and accuracy.

Versatile Uses of Wire and Diamond Discs

When it comes to metalworking and construction, wire and diamond discs offer specialized solutions for various tasks. Wire wheels excel in rust and paint removal, employing metal wire fibers to enhance abrasive quality. Depending on your needs, thicker bristles allow for quicker work, while thinner ones are better for precision tasks. On the other hand, diamond discs are your go-to for cutting dense materials like masonry and stone, featuring abrasive diamond shards that maximize cutting speed and durability.

Both tools necessitate the use of personal protective equipment (PPE) to guard against hazards such as flying debris from wire wheels and the risk of kickback from diamond discs. While diamond discs tend to be pricier, their efficiency makes them indispensable for critical tasks that demand both precision and speed. Ultimately, choosing the right disc can elevate your project’s outcome considerably.

Frequently Asked Questions

What Are the Different Types of Angle Grinder Wheels?

You’ve got cutoff wheels for precise metal cutting, grinding wheels for material removal, flap wheels for surface finishing, wire wheels for rust removal, and diamond wheels for durability. Always prioritize angle grinder safety and select the right wheel size.

What Is the Difference Between a Grinding Wheel and a Flap Wheel?

A grinding wheel’s aggressive material removal contrasts with a flap wheel’s finesse in surface finishing. While grinding wheel shapes and sizes excel in durability, flap wheels shine in applications that demand gentler, safer techniques. Choose wisely!

What Is the Difference Between a Grinding Wheel and a Cutoff Wheel?

A grinding wheel’s thicker design allows for shaping and smoothing, while a cutoff wheel’s thin profile excels in precise cutting. Consider wheel thickness, safety precautions, and compatibility when choosing for peak performance in your tasks.

What Are the Different Types of Grinding Wheels?

You’ll find grinding wheels made from various materials, like ceramic or aluminum oxide, suited for different applications. Sizes vary, affecting performance and compatibility. Always prioritize safety precautions and maintenance for best results, reading user reviews for guidance.

Conclusion

Understanding the various angle grinder wheel types is essential for optimizing your tool’s performance. Whether you’re cutting, grinding, or polishing, each wheel serves a specific purpose that can make or break your project. So, next time you’re gearing up for some metalwork, remember: you wouldn’t use a quill to write a novel when you’ve got a laptop at your fingertips. Choose the right wheel, and you’ll achieve professional results every time. Happy grinding!