Did you know plasma cutters, despite their impressive capabilities with metals, aren’t suitable for glass? Glass doesn’t conduct electricity and can’t withstand the intense heat plasma cutters generate, leading to shattering or cracking. Instead, consider alternatives like diamond blades or water jet cutting, which offer precision without the thermal stress. Curious about how these methods work and why they’re safer? Let’s explore the intricacies of glass cutting technology further.

Understanding Plasma Cutting Technology

Plasma cutting technology is a precise method that uses an electrical arc to transform air into a high-temperature plasma flame, capable of melting metals with efficiency. You’ll find that this technology excels when working with conductive materials like steel, aluminum, and brass.

The plasma arc is the key player here, as it ionizes the air to generate the intense heat needed for cutting. This results in impressive cutting efficiency, allowing you to achieve clean and precise cuts across various metal thicknesses.

Ionized air generates intense heat, enabling plasma arcs to deliver clean, precise cuts across metal thicknesses.

However, the process demands the material’s electrical conductivity to function effectively. Metals meet this requirement, enabling the plasma arc to maintain its cutting prowess.

The system’s design optimizes for metal’s properties, ensuring that your cuts are both swift and accurate. With plasma cutting, you harness a powerful tool that liberates your ability to manipulate metal with precision, providing an unparalleled level of detail and control in your work.

Why Glass Is Not Suitable for Plasma Cutting

When considering plasma cutting for glass, you face significant challenges due to its non-conductive nature, which impedes the electrical circuit completion essential for cutting.

Additionally, glass’s sensitivity to heat and uneven heat distribution from plasma cutting can cause cracking or shattering.

For effective cutting, you should explore safer alternatives like traditional glass cutters or oxy-acetylene torches, which offer better control and minimize damage risks.

Non-conductive Material Challenges

Though plasma cutters are highly effective for cutting conductive materials, they face significant challenges when dealing with non-conductive substances like glass.

Plasma cutting relies on completing an electrical circuit, which non-conductive materials like glass simply can’t support. This makes the cutting techniques used in plasma cutting ineffective. Glass doesn’t interact with the plasma arc due to its inability to conduct electricity, preventing the ionization process essential for cutting.

Using a plasma cutter on glass can lead to:

- Cracking or shattering from localized heat

- Emission of dangerous fumes

- Potential equipment damage

- Ineffective interaction with the plasma arc

For those seeking liberation from ineffective methods, traditional glass cutting tools or an oxy-acetylene torch offer safer, more reliable alternatives.

Heat Sensitivity Concerns

Due to its heat sensitivity, glass isn’t a suitable candidate for plasma cutting. Glass’s inherent vulnerability to thermal stress means that localized heat from a plasma cutter can easily cause cracking or shattering.

Unlike metals, glass doesn’t conduct electricity, preventing the plasma from ionizing to cut effectively. This results in uneven heat distribution, leading to potential damage instead of a clean cut.

Plasma cutting techniques are optimized for conductive materials, leaving glass susceptible to heat buildup and uneven melting.

Traditional cutting techniques like a glass cutter are far superior, offering smooth edges without risking thermal stress damage.

For those seeking precision and liberation from material constraints, understanding glass’s limitations is essential to choosing the right technique for your next project.

Effective Cutting Alternatives

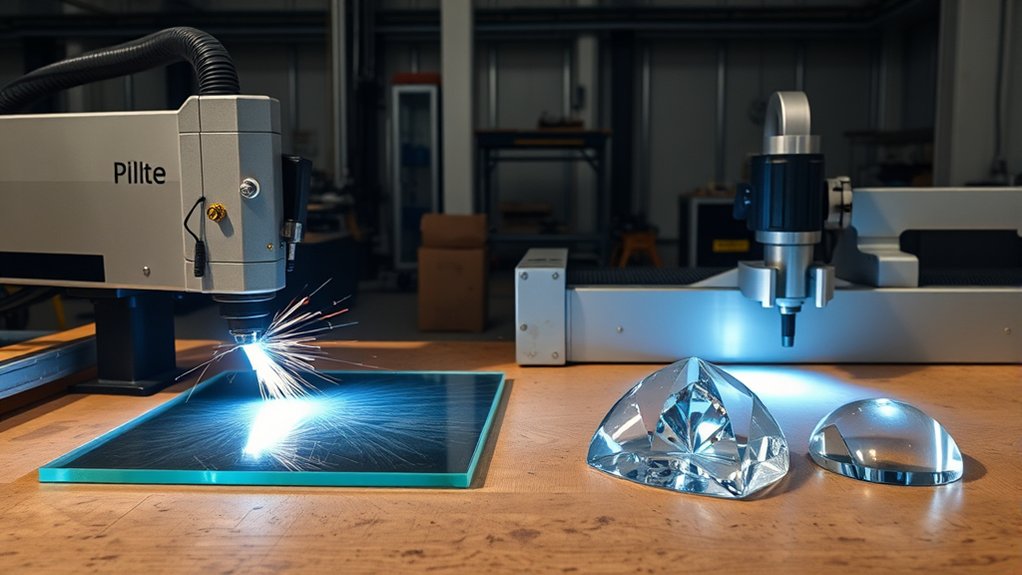

Several cutting alternatives prove more effective for glass than plasma cutters.

The plasma misconceptions surrounding glass cutting stem from the material’s non-conductive nature, which hinders the plasma arc’s interaction. The intense localized heat from plasma cutters can lead to cracking or shattering, making them unreliable for clean glass cuts.

Instead, you should consider these safer, more precise methods:

- Diamond Blades: Provide exceptional precision and are specifically designed for cutting glass without causing damage.

- Glass Scoring Tools: Allow for controlled, straight-line cuts by scoring and snapping.

- Oxy-Acetylene Torch: Offers more control over heat application, reducing the risk of cracking.

- Water Jet Cutting: Uses high-pressure water to cut glass smoothly and accurately.

These alternatives guarantee safety while achieving superior cutting results.

The Risks of Attempting to Cut Glass With Plasma

When you attempt to cut glass with a plasma cutter, you’re risking significant damage due to the material’s non-conductive nature. Plasma cutter limitations become evident as glass lacks the conductive properties necessary for ionization, a vital process for effective cutting. This mismatch in material properties means the cutter can’t perform its intended function, making glass cutting techniques designed for plasma cutters ineffective.

The risks don’t stop at ineffectiveness. The extreme temperatures generated can cause localized heat buildup, leading to uneven thermal expansion and, ultimately, cracking or shattering of the glass. Such events not only compromise the integrity of your project but also pose significant safety hazards.

Harmful fumes and debris can result from failed attempts, endangering both you and anyone nearby. For those seeking freedom from these risks, acknowledging these limitations is essential, steering you towards safer, more efficient methods for cutting glass.

Exploring Alternative Glass Cutting Methods

When considering alternative methods for cutting glass, traditional tools like glass cutters provide precision by scoring and applying pressure along a defined line.

For more advanced techniques, laser cutting offers high accuracy, though it requires careful calibration to prevent heat-induced damage.

Waterjet cutting, utilizing a high-pressure stream of water mixed with abrasive materials, effectively slices through glass without the thermal risks associated with other methods.

Traditional Glass Cutting Tools

Glass cutting requires precision and the right tools to guarantee clean and accurate results.

Traditional glass cutting tools, such as glass score cutters, are essential for this task. These tools employ glass scoring techniques, using a sharp blade to precisely score the glass surface, allowing it to break cleanly along the scored line. Proper cutting tool maintenance is vital to make sure the blade remains sharp and effective.

Consider these options for traditional glass cutting:

- Glass score cutters: Ideal for clean lines on annealed glass.

- Wet saws: Useful for intricate cuts or thicker glass pieces.

- Diamond blades: Perfect for detailed work requiring precision.

- Avoid plasma cutters: They generate excessive heat, risking damage.

Traditional methods offer a safer, controlled approach to glass cutting.

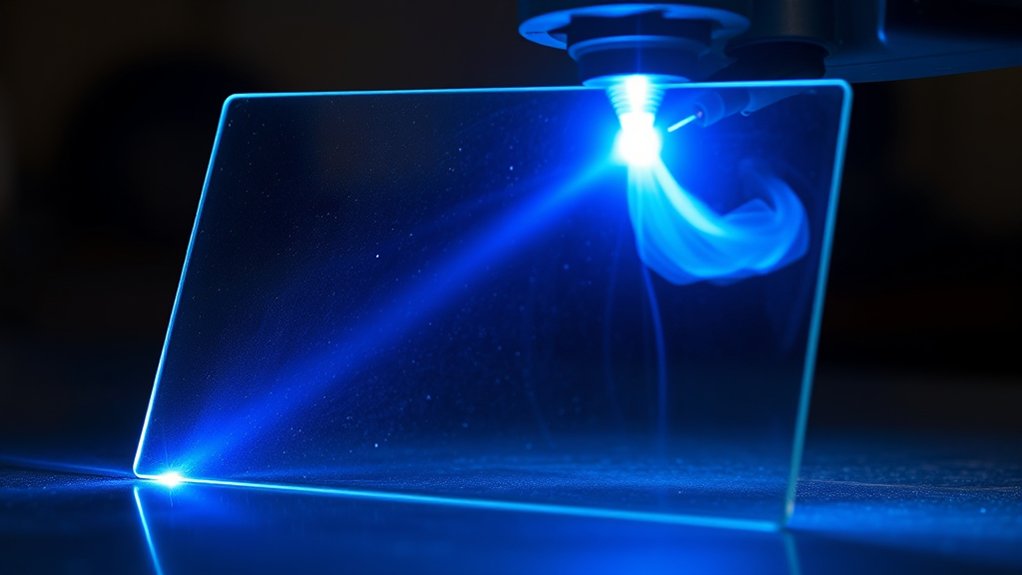

Laser Cutting for Glass

Although traditional methods of glass cutting have their merits, laser cutting offers a modern, precise alternative that minimizes the risk of shattering. By utilizing focused light, laser cutting advantages include its ability to achieve intricate design capabilities without the thermal stress problems associated with other techniques.

Unlike plasma cutting, which risks cracking due to high temperatures, laser cutting provides a controlled energy input, essential for preserving the integrity of annealed glass. This method is particularly valuable in industries like architecture and art, where precision is paramount.

To guarantee safety, always use appropriate protective equipment and maintain proper ventilation to avoid exposure to harmful fumes. Embrace the freedom of innovation with laser cutting, and explore your creative potential without compromising safety.

Waterjet Cutting Techniques

While exploring alternative methods for cutting glass, waterjet cutting emerges as a superior technique due to its precision and versatility.

This method employs a high-pressure water stream, often mixed with abrasives, to achieve precision cutting without the thermal stress that can lead to cracking.

Waterjet applications are ideal for intricate designs and complex architectural projects, as they allow for the creation of detailed shapes without the risk of shattering.

- Minimal heat generation: Reduces glass shattering risk.

- Environmentally friendly: No harmful fumes or waste.

- Versatile technology: Cuts metals, plastics, ceramics, and various glass thicknesses.

- Precision cutting: Ideal for complex and detailed designs.

The liberation from traditional limitations makes waterjet cutting an innovative choice in modern fabrication.

Benefits of Specialized Glass Cutting Tools

When working with glass, specialized cutting tools offer significant advantages by ensuring precision and minimizing the risk of damage.

These tools, such as glass cutters and diamond blades, are specifically designed to score and break glass accurately. The ergonomic design of many glass cutting tools enhances user comfort, allowing you to execute clean and precise cuts without excessive strain.

This is vital when working with larger sheets, where maintaining a steady hand is essential.

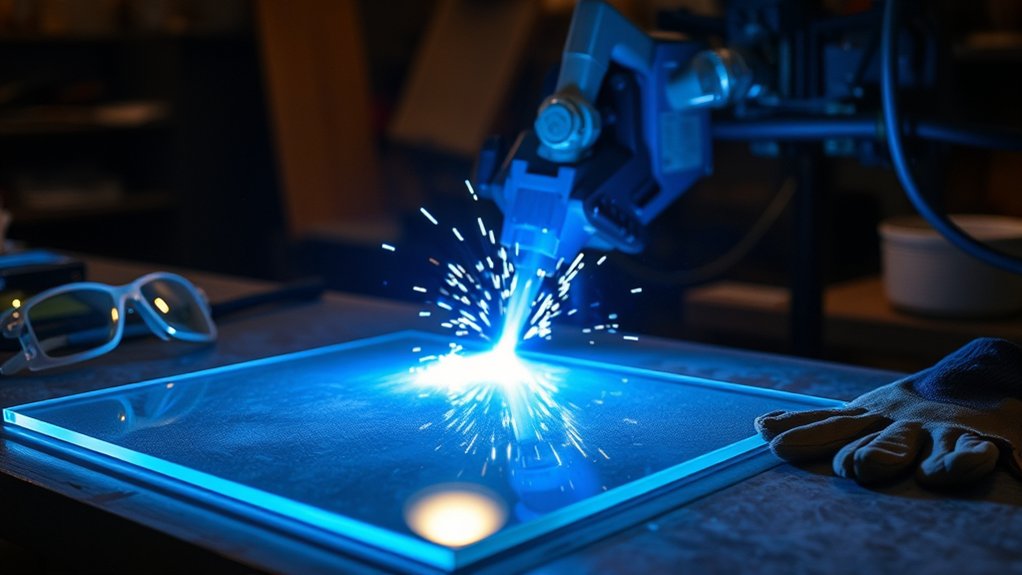

Safety Considerations When Working With Glass

Working with glass requires meticulous attention to safety due to its brittle and unpredictable nature. You must prioritize protective gear and proper ventilation to mitigate risks.

Since plasma cutting generates excessive heat, it can cause glass to shatter, releasing sharp fragments and harmful fumes. Instead, opt for safer methods like traditional glass cutters or an oxy-acetylene torch, which allow for more controlled and effective cutting.

To guarantee a safe working environment, consider the following precautions:

- Wear protective gear: Safety goggles and gloves protect against shards and cuts.

- Guarantee proper ventilation: Ventilation systems or masks can help avoid inhaling harmful fumes.

- Use appropriate tools: Specialized tools reduce the risk of shattering and promote precision.

- Maintain a clean workspace: A clutter-free area minimizes accidental contact with broken glass.

Comparing Plasma Cutting With Water Jet Cutting

When comparing plasma cutting and water jet cutting, you’ll find that water jet systems excel in precision and accuracy, especially with non-conductive materials like glass.

Plasma cutters, limited to conductive metals, struggle with glass due to its insulative properties, while water jets handle a broader range of materials including metals, stone, and plastics.

Considering cost and equipment, plasma systems might seem appealing for metals, but water jets offer a non-thermal cutting process that preserves material integrity, making them a more versatile and effective choice for diverse applications.

Cutting Precision and Accuracy

In the domain of cutting technologies, precision and accuracy are essential factors that differentiate plasma cutting from water jet cutting.

When comparing these cutting methods, you’ll find that plasma cutting is generally less precise due to heat-affected zones, which can alter material properties. In contrast, water jet cutting employs a high-pressure water stream with abrasives, achieving smoother edges without heat distortion.

Consider these points:

- Plasma cutting: Wider kerf width, more material waste.

- Water jet cutting: Narrow kerf, less need for additional finishing.

- Material properties: Water jets excel with delicate materials like glass.

- Plasma’s limitation: Ineffective on non-conductive materials.

While water jet cutting demands more investment, it guarantees superior accuracy and quality.

Understanding these differences empowers you to select the right tool for your projects.

Material Versatility and Limitations

Although both plasma and water jet cutting are prominent technologies regarding the material cutting domain, their capabilities differ considerably in relation to material versatility.

Plasma cutters are tailored for electrically conductive materials, excelling in cutting thicker metals efficiently. Yet, this limits their material applications, especially with non-conductive materials like glass. The heat-affected zone created by plasma cutting can induce thermal stress, posing a risk to delicate materials.

In contrast, water jet cutters utilize a high-pressure water stream combined with abrasives, enabling precise cuts across a broad spectrum of materials, including glass and ceramics, without heat damage.

This versatility makes water jet cutting a superior tool selection for applications requiring intricate designs on heat-sensitive materials, expanding your potential material applications beyond metal.

Cost and Equipment Requirements

Considering the cost and equipment requirements, plasma and water jet cutters each present unique advantages and limitations.

In your cost analysis, note that plasma cutters generally have a lower initial purchase price, making them appealing for metal fabrication with lower operating costs. However, their inability to cut non-conductive materials like glass limits their versatility.

Conversely, water jet cutters, despite a heftier initial investment, excel in equipment comparison by cutting a broader material range, including glass, without risking thermal damage. This makes them ideal for industries needing precision and intricate design work.

- Plasma cutting: Lower initial cost, limited to conductive materials.

- Water jet cutting: Higher initial cost, cuts diverse materials.

- Plasma: Faster for metals, not suitable for glass.

- Water jet: Precision in glass, justifies higher expense.

Choosing the Right Tool for Glass Projects

When you’re starting on a glass project, selecting the right tool is essential for achieving precise cuts without damaging the material. Understanding glass project aesthetics and effective glass cutting techniques is vital.

Plasma cutters, while powerful, aren’t suitable due to glass’s non-conductive nature. They generate localized heat, causing cracks or shattering—an aesthetic nightmare.

Instead, rely on tools designed for glass, like glass cutters or Oxy-Acetylene torches. These tools create clean breaks, preserving the beauty of your artistic work.

Opt for glass cutters or Oxy-Acetylene torches for clean, precise glass breaks.

For projects emphasizing style and form, use annealed glass, which is less likely to shatter compared to its tempered counterpart. This choice complements your creative vision while minimizing risks.

Prioritizing safety with the correct tools liberates you from potential hazards, allowing your artistry to flourish unimpeded. Embrace the precision these tools offer, ensuring your projects meet the highest standards of craftsmanship and aesthetic excellence.

Tips for Safe and Effective Glass Cutting

Choosing the right tools for your glass projects sets the stage for successful execution, but understanding safe and effective cutting techniques guarantees that execution is flawless.

Begin by selecting specialized glass cutters to accommodate varying glass thickness, ensuring precision and minimizing the risk of shattering. Properly support and secure the glass to prevent it from moving during the process, which can otherwise lead to mishaps.

Consider these essential tips to enhance your glass cutting experience:

- Protect your eyes: Always wear safety glasses to shield against glass shards.

- Wet cutting technique: Apply water to the glass surface to reduce heat and prevent thermal stress fractures.

- Master cutting angles: Achieve smooth cuts by maintaining consistent angles with your tool.

- Know your glass: Differentiate between annealed and tempered glass, as each requires distinct approaches.

Embrace these strategies to cut glass safely and effectively, releasing your creative potential without compromise.

Innovations in Glass Cutting Technologies

While traditional glass cutting methods have their merits, recent innovations in glass cutting technologies offer unparalleled precision and efficiency. Advanced laser cutting systems enable precise cuts without cracking, thanks to controlled heat application. Water jet cutting uses high-pressure water mixed with abrasives, delivering clean cuts devoid of thermal stress. CNC technology has revolutionized intricate designs, ensuring high accuracy and repeatability.

Consider these advanced cutting technologies:

| Technology | Method | Advantages |

|---|---|---|

| Laser Cutting | Localized heat application | Precision, minimal cracking |

| Water Jet Cutting | High-pressure water stream | Clean cuts, no thermal stress |

| CNC Cutting | Computer-controlled design | Intricate patterns, repeatability |

Automated diamond wire saws minimize waste and enhance safety, providing a non-destructive cutting solution. While plasma technology advancements have birthed specialized systems for glass, challenges in heat management persist. Embrace these glass cutting innovations to achieve a new level of craftsmanship and efficiency.

Frequently Asked Questions

Can Glass Be Repaired After a Failed Plasma Cutting Attempt?

You can’t repair glass after a failed plasma cutting attempt due to its irreversible structural damage. Explore alternative cutting techniques like waterjet cutting for precision, minimizing breakage risks, and ensuring a more effective glass repair approach.

What Are the Costs Associated With Glass Cutting Tools?

You’ll find costs vary. Conduct a cost analysis comparing diamond saws and water jet cutters. Diamond saws are typically more affordable, but water jet cutters offer precision. Tool comparison reveals a balance between budget constraints and cutting accuracy.

How Do Environmental Factors Affect Glass Cutting Methods?

You might think glass cutting is immune to weather whims, but temperature effects can warp precision. Humidity impacts your tool’s grip, adding unexpected challenges. Embrace freedom by mastering these elements, ensuring your cuts are consistently flawless.

Can Plasma Cutting Be Used for Artistic Glass Designs?

You can’t use a plasma cutter for artistic glass designs. It risks shattering glass due to intense heat. Explore alternative artistic techniques like waterjet cutting. Implement safety measures to guarantee precision and protect your creative process.

What Are the Training Requirements for Using a Plasma Cutter?

“Better safe than sorry.” You need operator certification and must follow safety protocols diligently. Training covers equipment handling, operation, and emergency procedures, empowering you with the skills and confidence to operate a plasma cutter independently and safely.

Conclusion

When you approach glass cutting, think of it as crafting a delicate dance rather than wielding a fiery sword. Plasma cutters, with their searing heat, are bull in a china shop, risking shattering beauty. Instead, embrace specialized tools or the gentle caress of water jet cutting. These methods are your steady hand, ensuring precision and safety. So, choose wisely, for glass demands respect and finesse, turning potential disasters into a symphony of clean, controlled cuts.