Imagine AR500 steel as a fortress of durability, a challenge for many cutting methods. You might wonder if a plasma cutter can breach its defenses. The answer lies in precise settings: higher amperage and swift speed are keys to minimizing the heat-affected zone. Ensuring the edge quality remains intact is essential to avoid brittleness. Are you equipped with the knowledge to tackle this formidable steel with finesse?

Understanding AR500 Steel and Its Characteristics

AR500 steel is a robust material known for its impressive hardness and abrasion resistance. In your quest for materials that endure the harshest conditions, understanding AR500’s properties is essential.

AR500 steel: unmatched in hardness and durability, perfect for enduring the harshest conditions.

It boasts a hardness rating of 460 to 544 on the Brinell Hardness Scale, a demonstration of its high-strength capabilities. This level of hardness is achieved through the integration of manganese and carbon with iron, giving it unparalleled resistance to impact and abrasion.

When considering the properties overview, AR500’s toughness makes it indispensable in environments like mining and heavy machinery. Its hardness implications can’t be overstated; while it offers remarkable durability, this very characteristic demands specific handling techniques.

Standard cutting methods fall short, necessitating specialized equipment to reveal its full potential. As you explore AR500 steel‘s characteristics, appreciate its ability to withstand demanding applications while challenging you to adapt and innovate.

Embrace this opportunity to liberate your engineering prowess.

Plasma Cutting Techniques for AR500 Steel

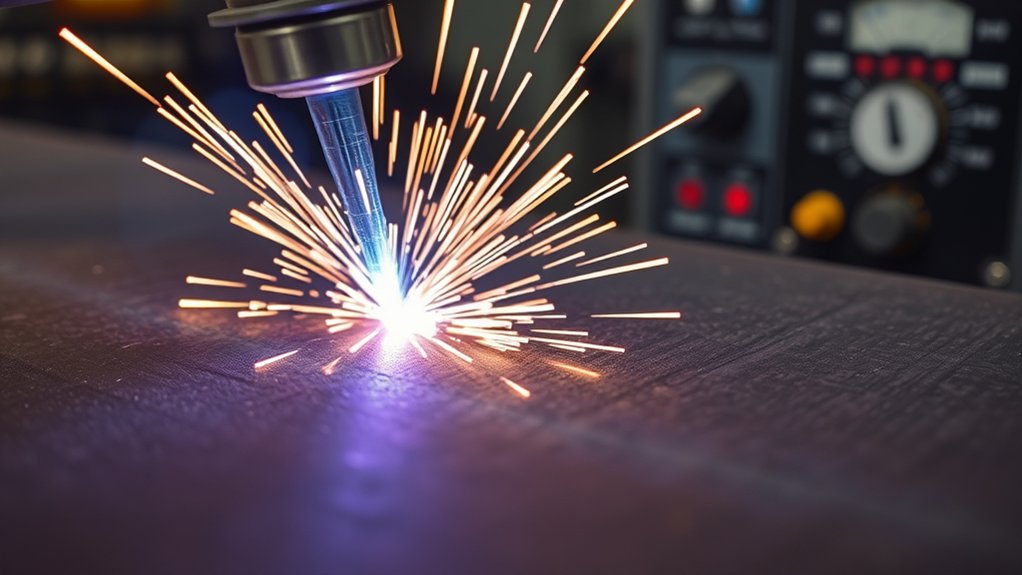

Harness the precision of plasma cutting techniques to tackle the formidable AR500 steel. When working with this robust material, precise control over cutting speed and amperage settings is essential.

AR500 steel thrives under a higher amperage combined with a swift cutting speed. This approach minimizes the heat-affected zone (HAZ) and preserves the integrity of the cut edges.

Before beginning, verify your plasma cutter is suited for the material’s thickness. Different thicknesses demand specific settings to maintain efficiency.

A clean and smooth surface before cutting reduces post-process corrections, improving edge quality considerably. Additionally, integrating a water table during the cutting process can be beneficial. It dissipates heat effectively, mitigating potential weak spots on the steel’s edge.

Managing Heat-Affected Zones and Edge Quality

When cutting AR500 steel, managing the heat-affected zone (HAZ) is essential to maintaining the integrity of the material. Plasma cutting can introduce brittleness if cutting speed and power aren’t optimized. As the AR500 plate thickens, the HAZ widens, demanding precise heat management.

You need to fine-tune your plasma cutter settings according to the material’s thickness to guarantee effective edge preservation. A well-adjusted cutter yields a minimal HAZ, generally less than 0.001 inch thick, preserving the steel’s robustness.

To enhance edge quality and minimize thermal distortion, consider using a water table during the process. This technique aids in cooling the edges efficiently.

Balancing cutting speed and amperage is key. High-speed, high-amperage settings are your allies in reducing HAZ, consequently improving edge quality.

Safety and Equipment Considerations

Managing the heat-affected zone is just one aspect of cutting AR500 steel that’s essential for maintaining material integrity. Guaranteeing safety involves donning the right protective gear: gloves, a face shield, and flame-resistant clothing. These safeguard you from sparks and intense heat, vital when dealing with powerful plasma arcs.

Ventilation requirements can’t be overlooked; proper airflow prevents the dangerous buildup of fumes and gases emitted during the cutting process.

Adhering strictly to the plasma cutter’s operation instructions optimizes settings based on the AR500 steel’s thickness, minimizing overheating risks. Incorporating a water table effectively reduces thermal distortion and weak spots, enhancing cut quality.

Regularly maintain and calibrate your plasma cutter to guarantee consistent performance and avoid inconvenient breakdowns. Each of these steps liberates you from potential hazards, enabling you to focus on precision and efficiency while cutting AR500 steel with confidence and control.

Comparing Plasma Cutting With Other Methods

Though several methods exist for cutting AR500 steel, plasma cutting stands out due to its efficiency and cost-effectiveness, especially for thicker plates.

With superior plasma efficiency and cutting speed, it’s an ideal choice when you need to balance budget and time constraints. However, this method can produce a larger heat-affected zone (HAZ) than fiber laser cutting, which may compromise edge brittleness if not carefully managed.

Fiber laser cutting offers precision but falls short in speed compared to plasma, especially on thicker materials.

Conversely, waterjet cutting excels with its cold-cutting capability, preserving the integrity of heat-treated AR500 steel with minimal HAZ. Yet, it’s typically more costly, making plasma a more attractive option for budget-conscious projects.

Ultimately, while plasma cutting might slightly compromise edge quality, its rapid cutting speed and cost benefits make it a liberating choice for many situations where efficiency is paramount.

Frequently Asked Questions

How Does AR500 Steel Thickness Affect Plasma Cutting Settings?

AR500 steel thickness directly impacts plasma cutting settings. You’ll need to adjust power settings for thicker steel to guarantee penetration, while optimizing cutting speed prevents slag. Precision allows for control, offering you the freedom to achieve clean cuts.

Can Water Tables Improve Plasma Cutting Results for AR500 Steel?

Yes, water tables wonderfully enhance plasma cutting results for AR500 steel. They reduce residual heat, resulting in refined cuts and improved cutting accuracy. You’ll achieve cleaner edges, minimizing material distortion and maximizing your mastery over metal manipulation.

What Are Common Mistakes When Plasma Cutting AR500 Steel?

You’re often making mistakes by neglecting proper edge preparation and using incorrect plasma cutting techniques. Guarantee ideal settings; otherwise, you’ll compromise precision and edge quality. Mastering these skills liberates your craftsmanship, empowering accurate, high-quality cuts on AR500 steel.

How Does Consumable Quality Impact AR500 Steel Plasma Cutting?

Consumable quality can turn frustration into triumph. High-grade consumable types enhance precision, reduce dross, and extend electrode lifespan. Choose wisely, and you’ll master AR500 cutting with accuracy, ensuring freedom from frequent replacements and erratic edge quality.

Are Specific Plasma Cutter Brands Better for AR500 Steel?

Yes, certain plasma cutter brands excel in cutting AR500 steel by delivering superior cutting performance. You’ll find brands with advanced technology, precise arc control, and robust power, ensuring clean cuts and liberation from subpar results. Choose wisely.

Conclusion

Cutting AR500 steel with a plasma cutter is like walking a tightrope; balance is key. By optimizing amperage and speed, you keep the heat-affected zone in check, maintaining the steel’s integrity. Don’t forget to clean the surface and consider a water table to dissipate heat effectively. While plasma cutting offers precision, it demands respect and understanding of the material’s nature. With careful execution, you can achieve clean, precise cuts without compromising the steel’s durability and strength.