Plasma Cutter 110V or 220V: Which Should You Choose?

Plasma cutters: 110V or 220V—discover which suits your needs best for efficiency and power, and unlock the secrets to precision and versatility.

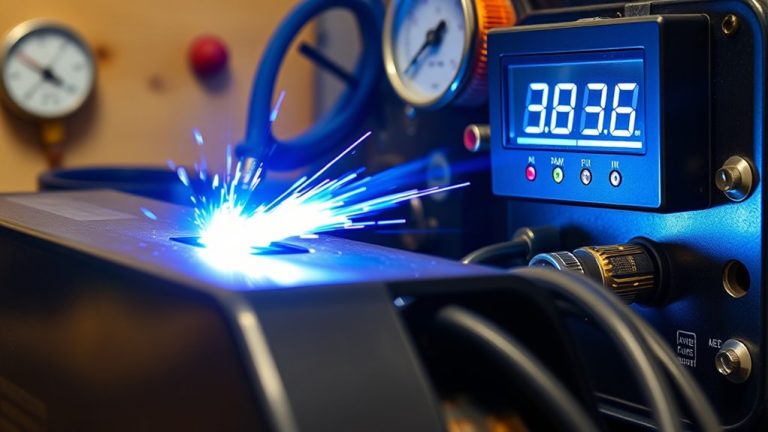

Power determines cut capacity and reliability. Dual-voltage plasma cutters draw fewer amps and cut thicker on 240V than 120V. Check the nameplate/input current at your target output and duty cycle, then match a dedicated circuit and breaker (small 120V units often need 20A; mid/heavy 240V machines commonly require 30–50A—follow your manual). Keep extension cords short and heavy-gauge (10–12 AWG / 2.5–4 mm²) to limit voltage drop. Power-factor-corrected (PFC) models run steadier on long cords and generators. If using a generator, choose clean power with continuous watts ≈2–3× the cutter’s input kW and good voltage regulation. Verify plug/receptacle type, grounding, and local electrical codes—or consult a qualified electrician.

Plasma cutters: 110V or 220V—discover which suits your needs best for efficiency and power, and unlock the secrets to precision and versatility.

Know the perfect generator size for your plasma cutter with our detailed sizing chart and tips—discover the secret to seamless metal cutting!

Investigate the crucial amperage needed for your plasma cutter to ensure maximum efficiency and safety—discover how to optimize your workshop's power setup.