You run a CNC plasma cutter by converting toolpaths into G‑code that drives servo or stepper motors with encoder feedback for precise motion. A torch height controller samples arc voltage to maintain standoff, stabilizing kerf and cut quality. The power supply ionizes gas, forming a constricted arc that melts and ejects metal at speed. Success depends on calibrated motion, THC tuning, and consumable health—get any of these wrong, and tolerances drift fast. Want the exact setup steps?

What a CNC Plasma Cutter Does and Why It’s Used

Precision defines a CNC plasma cutter: it drives an ionized gas arc to melt and eject metal, producing clean, repeatable cuts in steel, aluminum, and other conductive alloys.

You program geometry; the CNC system executes paths with automated torch motion to deliver accurate profiles and consistent kerf. The result is high throughput on mid-to-thick plate with tight tolerances and minimal post-processing.

You’ll use it when you need speed and metal versatility across gauges and alloys. Torch Height Control (THC) reads arc voltage to maintain standoff, stabilizing arc energy density, improving edge quality, and extending consumable life.

That control lets you hold pierce heights, cut heights, and lead-ins precisely, reducing rework and scrap.

Typical CNC applications include production of brackets, gussets, frames, flanges, and architectural patterns. You can process varying thicknesses on one table, shifting jobs without tooling changes.

The process scales from single prototypes to batch manufacturing with predictable cycle times.

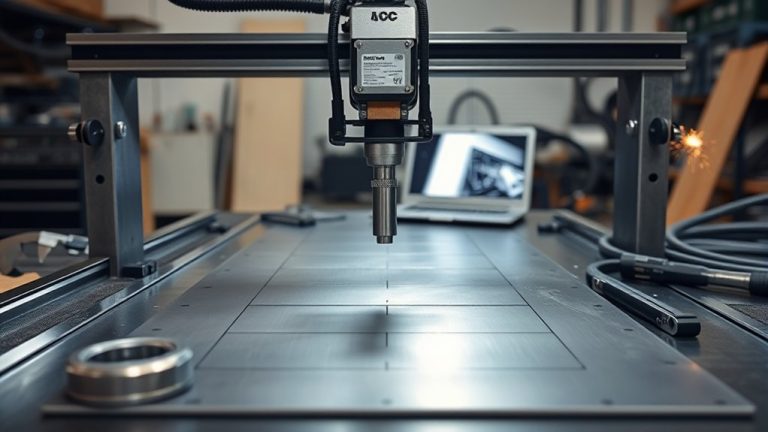

Motion Control: Motors, Drives, and Path Accuracy

Two core elements drive path accuracy in a CNC plasma cutter: the motor/drive system and the feedback loop. You command motion with G-code; the controller translates each segment into axis trajectories. Selecting motor types (stepper vs. servo) and matching drive systems determines torque bandwidth, velocity ripple, and positional fidelity along X, Y, and Z. Servos with high‑resolution encoders close the loop, correcting error in real time. Steppers can work open-loop but benefit from encoders for fault detection. Linear guides and rails reduce friction and chatter, enabling smooth acceleration profiles and consistent kerf geometry. During cutting, the feedback loop monitors position and adjusts velocities to compensate for material shift or gantry compliance, preserving path accuracy.

| Component | Function | Metrics to Track |

|---|---|---|

| Motors (stepper/servo) | Generate motion | Torque, inertia match |

| Drives | Current/velocity control | Loop bandwidth |

| Encoders | Position feedback | Counts/rev, latency |

| Controller | G-code to trajectories | Interp. tolerance |

| Guides/Rails | Smooth linear motion | Straightness, preload |

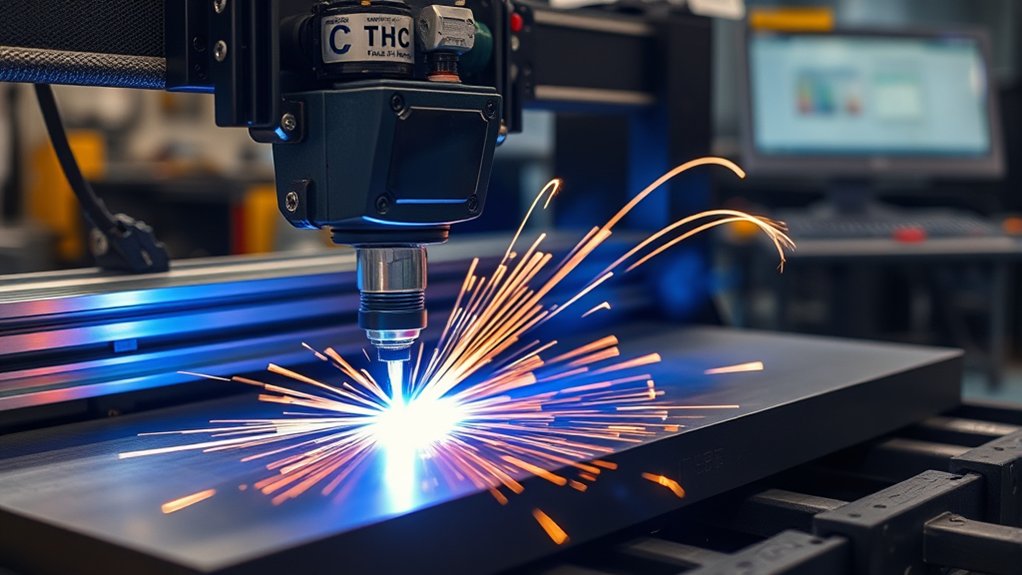

Torch Height Control: Elements, Setup, and Operation

Although motion control sets the path, torch height control (THC) locks in cut quality by holding a precise arc length above the work. You use a motor-driven positioner to execute torch adjustments in real time, driven by arc-voltage feedback. The control console coordinates commands and feedback from the plasma interface, regulating torch-to-work distance to stabilize kerf geometry and reduce bevel.

Begin with Initial Height Sensing (IHS): probe the surface, establish pierce height, then drop to cut height. Set voltage settings based on material, thickness, and amperage; typical ranges are 100–200 VDC. Calibrate by cutting a test coupon, measuring edge angle and dross, and nudging target voltage until the bevel approaches zero and dross minimizes.

During cutting, the THC closes the loop—if voltage rises, it lowers the torch; if voltage falls, it raises it—maintaining standoff despite plate warp. A tuned THC plus trained operators extends consumable life, improves consistency, and reduces downtime.

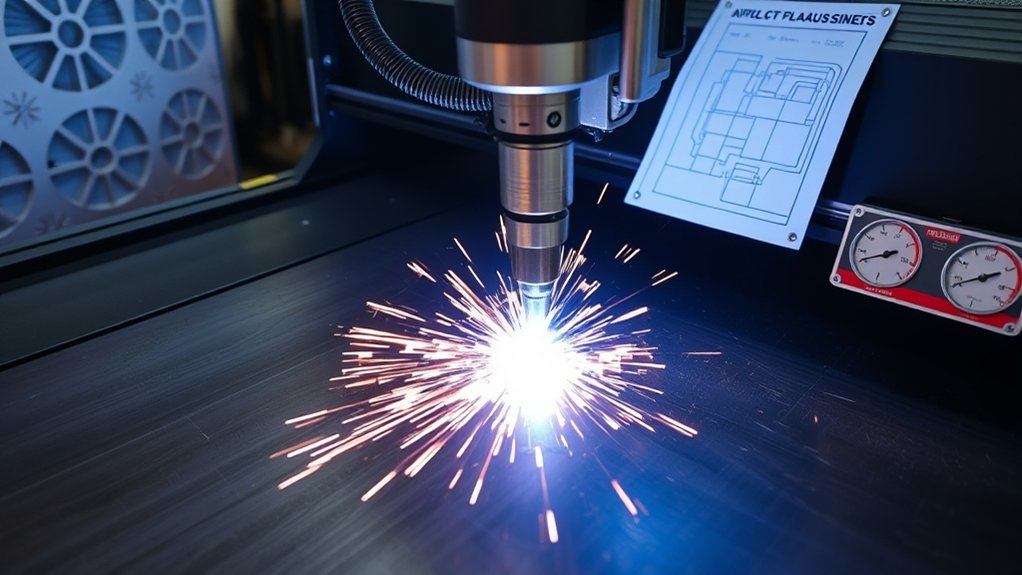

Arc Basics: Plasma Generation, Voltage, and Standoff

While the motion system defines the path, the arc does the work: you create plasma by adding energy to a process gas until it ionizes, forming a conductive column that reaches temperatures up to ~30,000°C. Those plasma properties deliver current density and heat flux sufficient to sever metal rapidly. You control the arc electrically: arc voltage rises as torch-to-work standoff increases and falls as it decreases. Typical cutting voltage runs ~100–200 VDC, depending on nozzle, current, and speed.

Maintain a 1–2 mm standoff to balance kerf width, dross, and bevel. Voltage regulation links standoff to closed-loop control: the THC reads arc voltage in real time and corrects height to hold the setpoint. Calibrate the target voltage to your consumables and amperage; small errors shift bevel angle and waste energy.

| Parameter | Typical Range | Effect |

|---|---|---|

| Arc Voltage | 100–200 VDC | Tracks standoff |

| Standoff | 1–2 mm | Minimizes bevel |

| Temperature | Up to 30,000°C | Enables clean severing |

From File to Finished Part: Workflow, Cut Quality, and Maintenance

Before an arc ever strikes, your process starts in software: import a DXF or draft geometry in CAD, apply cut rules (lead‑ins/outs, kerf compensation, tabbing), and post a CAM toolpath with verified pierce sequence and cut order.

Next, nest parts to maximize sheet coverage; lock grain or heat-affected boundaries as required and track drops to improve material yield across jobs.

Validate toolpaths with dry-run simulation to confirm clearance, THC behavior, and cycle time for workflow optimization.

On the machine, set amperage, cut speed, pierce height, and cut height per thickness and consumable spec.

Monitor arc voltage, dross, and edge bevel; adjust speed ±5–10% and height ±0.1 mm to stabilize kerf and minimize rework.

Use appropriate fume control—water table depth or downdraft CFM—to maintain visibility and regulatory compliance.

Maintain daily: inspect nozzle/electrode wear, clean shield and ohmic surfaces, verify air quality (dry, oil‑free, correct pressure), square slats, and update consumable life records.

Frequently Asked Questions

What Safety Gear Is Essential When Operating a CNC Plasma Cutter?

You need safety goggles, a full-face shield, leather gloves, flame-resistant jacket, welding apron, hearing protection, steel-toe boots, and a respirator. Keep a fire extinguisher nearby. Verify PPE ratings: ANSI Z87.1, NRR ≥25 dB, FR category 2+, P100 filtration.

Can a Plasma Cutter Engrave or Mark Without Fully Cutting?

By Zeus, yes—you can plasma mark without full penetration. You’ll reduce current, increase standoff, raise travel speed, and shorten duty cycles. Employ low-amp plasma marking and controlled engraving techniques, verifying depth with micrometer checks and consistent parameter logging.

How Does Shop Ventilation Affect Plasma Cutting Fumes and Dust?

Shop ventilation directly reduces plasma-cutting fume concentration and dust resuspension. You implement local fume extraction, maintain negative pressure, optimize airflow rates (e.g., 100–150 fpm capture), and monitor particulates/metals to protect air quality, operator exposure (ppm/mg/m³), and equipment cleanliness.

What Materials Are Unsuitable or Hazardous to Cut With Plasma?

You must avoid hazardous materials and unsuitable metals: galvanized steel, cadmium-coated parts, lead, beryllium copper, magnesium, and painted/unknown alloys. In a shop incident, cutting galvanized plate spiked zinc fumes to 8× limits, triggering metal fume fever despite ventilation.

How Loud Is Plasma Cutting, and Do I Need Hearing Protection?

Plasma cutting noise typically reaches 90–120 dB at the torch. You need hearing protection necessity: wear NRR 25–33 dB earmuffs or earplugs. Measure levels with a dosimeter; account for compressor, fume extractor, and enclosure attenuation.

Conclusion

You’ve seen how a CNC plasma cutter turns digital intent into metal reality. You command motion control to trace paths with encoder-verified precision, let THC lock standoff via arc voltage, and harness plasma’s heat to optimize kerf and edge quality. Treat the workflow like an instrument panel: validate files, calibrate drives, tune voltage windows, verify consumables, and log cut metrics. Do that, and the machine becomes a scalpel of lightning—fast, exact, and repeatable across jobs and alloys.