Wiring a plasma cutter might seem challenging, but it’s a fascinating blend of engineering and safety. Whether you’re handling 120V or 240V, knowing the right configurations and breaker setups is vital. You’ll need to connect wires accurately and make sure grounding is flawless to prevent hazards. Adhering to electrical codes is non-negotiable. Curious about how to troubleshoot common issues or guarantee peak performance? Let’s explore the essential steps and safety measures involved.

Understanding 120V Wiring Configurations

When you’re setting up a plasma cutter, understanding 120V wiring configurations is important for both performance and safety. You must adhere to wiring standards to guarantee compliance and operational integrity.

The common plug types you’ll encounter for 120V connections are the 5-15 for typical household outlets and the 5-20 P for setups demanding higher amperage. It’s essential to recognize these outlet types for proper equipment compatibility.

Following the National Electrical Code (NEC) is non-negotiable, as it allows derating for duty cycle-limited machines, assuring safe operation.

Adhering to the NEC ensures safety by permitting derating for machines with limited duty cycles.

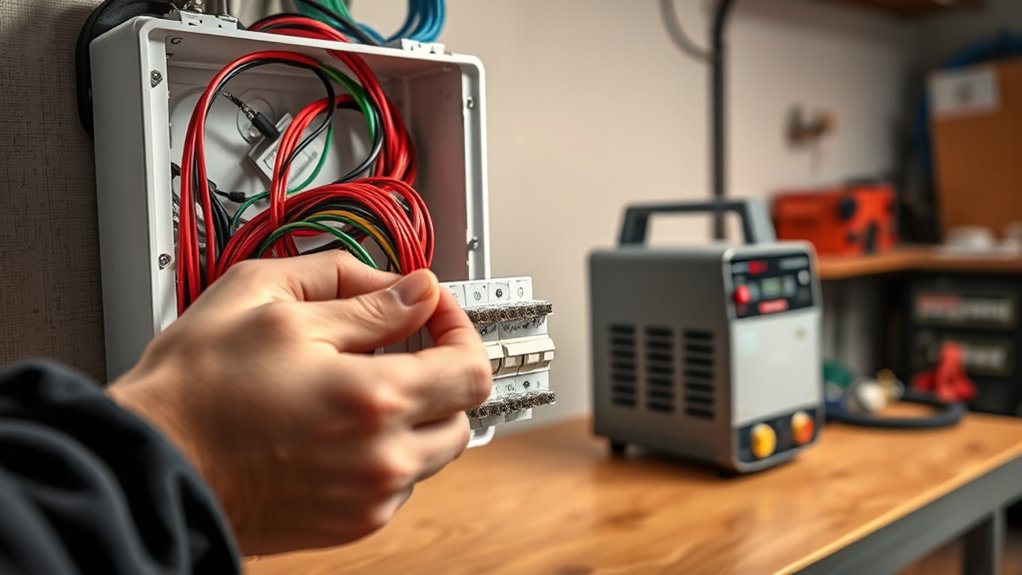

Begin by connecting the black wire to the gold screw (hot), the white wire to the silver screw (common), and the green wire to the green screw (ground). Tightening the strain relief securely is critical to prevent cable pull-out, which could lead to safety hazards.

Setting Up 240V Connections

Setting up a 240V connection for your plasma cutter involves a few critical steps to guarantee safety and functionality.

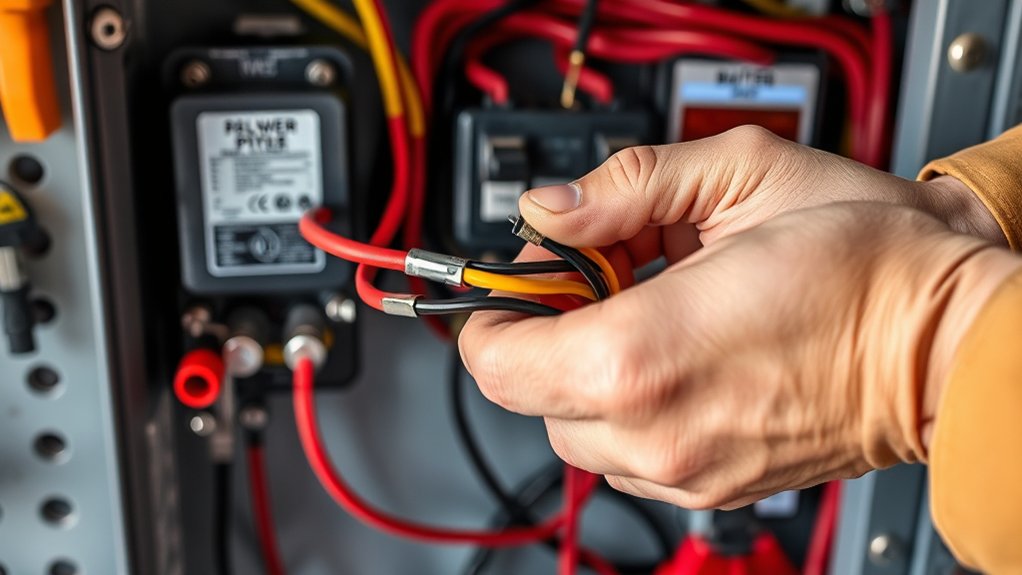

Begin by using a standard three-prong receptacle (6-50 R) and matching plug (6-50 P) to ascertain circuit compatibility. Refer to wiring diagrams specific to your equipment for precise guidance. In a 240V setup, both the white and black wires serve as hot wires. Connect the white wire to the smaller prong and the black wire to the larger prong to align with your device’s requirements.

Securely fasten all screws to prevent loose connections, which can lead to operational issues or safety hazards. Properly tighten the strain relief to avoid cable pull-out, ensuring a stable and secure connection.

Always adhere to local electrical codes and regulations during installation to maintain safety and compliance. These precautions help you achieve a reliable and safe electrical setup for your plasma cutter.

Choosing the Right Breakers for Your Plasma Cutter

Although selecting the right breakers for your plasma cutter may seem straightforward, it’s essential to confirm they align with the equipment’s electrical demands.

For a 120V plasma cutter, use a 15 amp breaker for standard circuits or a 20 amp breaker for higher amperage requirements. This guarantees that your breaker won’t trip during operation, providing seamless functionality.

When dealing with a 240V plasma cutter, opt for a double-pole breaker with a voltage rating suitable for the cutter’s needs, typically between 30 to 50 amps. Always consult the manufacturer’s guidelines to verify specific breaker types and ratings, as improper sizing can lead to equipment damage or safety hazards.

Incorporating breakers that comply with the National Electrical Code (NEC) is essential for both safety and peak performance.

Regular inspections for wear or malfunction are important, as these issues can impact safety and efficacy. Proper breaker selection is key to confirming your plasma cutter operates safely and efficiently.

Ensuring Proper Strain Relief and Wire Connections

Make certain that the strain relief is tightened properly to prevent cable pull-out, which is essential for both safety and the longevity of your plasma cutter’s wiring.

When making wire connections, always tighten the screws securely to prevent loose connections that can lead to electrical hazards or equipment failure.

Regular inspections of these components for wear or damage will help maintain peak performance and safety.

Secure Cable Strain Relief

Properly securing cable strain relief is essential to maintaining safe and efficient operation of your plasma cutter.

Effective cable management plays a critical role in electrical safety, preventing cable pull-out and reducing electrical hazards. Guarantee the strain relief is tight enough to grip the cable firmly, avoiding wear and damage over time.

In 120V configurations, adjust the strain relief to fit the plug type, whether 5-15 or 5-20. For 240V setups, guarantee it accommodates the three-prong system (6-50 R and 6-50 P).

Always verify that the strain relief complies with local codes and standards.

- Prevent cable pull-out

- Guarantee firm cable grip

- Adjust for 120V or 240V setups

- Comply with local codes

- Promote electrical safety

Tighten Wire Connection Screws

Fasten wire connection screws securely to prevent any loose connections that could lead to operational problems or safety hazards.

Use precise wire tightening techniques to verify a robust connection. For 120V setups, tighten the black wire on the gold screw (hot), the white wire on the silver screw (common), and the green wire on the green screw (ground).

In 240V configurations, both black and white wires are hot; secure the white wire to the smaller prong and the black to the larger.

After wiring, check the strain relief mechanism’s tightness to prevent cable pull-out.

Regularly apply connection maintenance tips by inspecting wiring connections for wear or loosening, especially in high-duty cycle applications, to guarantee consistent performance and safety.

Adhering to Local Electrical Codes and Standards

When installing a plasma cutter, it’s vital to comply with local electrical codes and standards to guarantee both safety and peak performance. Understanding local regulations secures your wiring setup meets safety compliance requirements, preventing potential hazards.

Begin by confirming your wiring configuration aligns with the National Electrical Code (NEC), especially for dual voltage systems (120V/240V). This alignment is significant for ideal safety and functionality.

- Wire Gauge Selection: Use the correct wire gauge for your circuit and breaker size to prevent overheating.

- Circuit Breaker Specification: Install breakers that meet local codes—15 amp for 120V circuits and 30 amp for 240V circuits.

- Regulatory Updates: Regularly review updates to your local electrical codes to maintain compliance.

- Voltage System Consideration: Pay attention to dual voltage requirements as specified by NEC.

- Inspection and Verification: Conduct thorough inspections to confirm all components meet local standards.

Prioritizing these elements will secure a safe and efficient plasma cutter operation.

Troubleshooting Common Wiring Issues

When troubleshooting common wiring issues with your plasma cutter, start by confirming that the power supply voltage matches the cutter’s requirements and that your wiring configuration is accurate.

Inspect all connections for signs of looseness or corrosion, as these can lead to intermittent power loss or complete operational failure.

Always verify the circuit breaker is functional and not tripped due to overloads or short circuits, addressing any such issues promptly to maintain safety.

Identifying Loose Connections

Making sure your plasma cutter operates efficiently often starts with identifying loose connections, a common but easily overlooked issue.

Begin with a visual inspection, checking for frayed wires or loose screws at the terminals. Intermittent power loss or flickering lights during operation often signal these problems.

Here’s how you can proceed safely and effectively:

- Visual inspection: Look for visible damage or loose components.

- Tug test: Gently pull on wires to check for movement, making certain secure connections.

- Continuity testing: Use a multimeter to verify proper current flow.

- Safety first: Always turn off power and unplug the unit before inspecting.

- Tighten connections: Make sure all screws and terminals are properly secured.

These steps help maintain a stable, efficient plasma cutter setup.

Resolving Incorrect Wiring

Having identified and addressed any loose connections, it’s important to tackle incorrect wiring configurations that could compromise your plasma cutter’s performance.

Begin by ensuring the black wire connects to the gold screw and the white wire to the silver screw in a 120V circuit to prevent reverse polarity issues. For 240V setups, verify both hot wires—black and white—are securely fastened to their respective prongs to avoid overheating.

The ground wire must be correctly attached to the green screw for ideal electrical safety and functionality. If your plasma cutter isn’t working, inspect the strain relief clamp for proper tension.

In single-phase 240V configurations, tape the red wire to prevent incorrect circuit connections, ensuring seamless operation and preventing potential hazards.

Frequently Asked Questions

Can I Use an Extension Cord With a Plasma Cutter?

Yes, you can use an extension cord with a plasma cutter, but make certain it meets extension cord limitations. Verify the cord’s gauge and length for plasma cutter compatibility, and prioritize safety by avoiding voltage drops or overheating risks.

What Personal Protective Equipment Is Necessary When Wiring a Plasma Cutter?

Imagine sparks flying as you work; you’ll need welding gloves to shield your hands from heat and safety goggles to protect your eyes from debris. Always prioritize safety by wearing the right gear when wiring a plasma cutter.

How Do I Determine the Correct Wire Gauge for My Plasma Cutter?

Check your plasma cutter’s manual for the required amperage. Then, use a wire gauge chart to select the correct wire size. Always prioritize safety and verify the wire gauge can handle the current without overheating.

How Can I Safely Test if My Wiring Is Correct?

To verify your wiring, perform voltage testing using a multimeter. Ascertain all connections match the circuit specifications. Turn off power first, then test each wire. This confirms correct wiring and prioritizes safety. Always follow proper procedures.

What Should I Do if My Plasma Cutter Trips the Breaker Frequently?

If your plasma cutter trips the breaker like clockwork, first check for overloaded circuits. Use proper breaker reset techniques, ensuring connections are tight. Evaluate your plasma cutter troubleshooting steps, focusing on wiring integrity and correct amperage. Always prioritize safety.

Conclusion

Wiring your plasma cutter is like assembling a precision machine—every detail matters. Verify your 120V and 240V connections are tight, breakers are correctly chosen, and grounding is inspected. Just like a well-tuned instrument, proper wiring guarantees safety and efficiency. Adhere to local electrical codes, and if issues arise, troubleshoot with a methodical approach. By prioritizing safety and precision, you’ll achieve maximum performance and reliability in your plasma cutting endeavors.