You’re maintaining a Powermax Pro 30 and need the right consumables—start with electrode 220478, nozzle 220480, and retaining cap 220483. Check your exact Powermax30 variant for compatibility, especially if mixing 30/45 parts. Inspect every 20–30 hours; replace at the first signs of pit depth or nozzle orifice ovaling to keep arc quality stable and reduce dross. Next, you’ll want the cross-reference list and upgrade paths that can cut costs and downtime.

Powermax30 System Overview and Compatibility

For Powermax30 users, start by confirming your system variant—legacy Powermax30, Powermax30 XP, or Powermax30 AIR—since consumable fitment and air requirements differ across models.

You’ll match torches and parts by series to guarantee proper arc voltage and airflow, which directly impacts Powermax30 applications and plasma cutting benefits. The platform is rated to 30 A for cutting and gouging on mild steel, stainless, and aluminum, and it accepts FineCut options for tighter kerf and reduced dross on thin stock.

When planning replacements, verify torch family and catalog part numbers before ordering to avoid cross-series mismatches.

Check that your model supports FineCut SKUs for precision work and uses the correct retaining hardware for standard versus gouging setups.

Verify FineCut compatibility and use the correct retaining hardware for standard or gouging precision setups.

Confirm air delivery: shop air for legacy and XP; integrated compressor for AIR affects pressure tuning and duty cycle expectations.

Maintain a single-source list of approved assemblies so you can swap parts efficiently without compromising cut quality or system reliability.

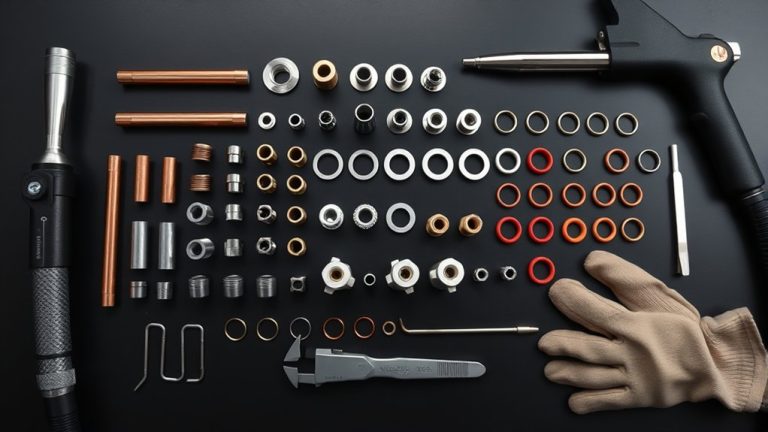

Essential Consumables: Nozzles, Electrodes, Swirl Rings

Consumables drive cut quality and uptime on the Powermax Pro 30, so match nozzles, electrodes, and swirl rings to the correct torch family and catalog SKUs before ordering.

Use only Pro 30–specified parts to avoid misalignment, gas leakage, and poor arc starts.

Nozzles focus the arc; verify the amperage rating and orifice spec on the SKU before purchase. Expect about $5.94 each.

Inspect daily for out-of-round wear and dross buildup; nozzle maintenance—clean, replace at first tapering—prevents bevel and kerf widening.

Electrodes initiate and carry the arc; plan replacements at the first copper mushrooming or deep hafnium pit. Typical cost is $9.16 per unit.

Track electrode life by cut length or pierce count; replace proactively to protect the nozzle.

Swirl rings stabilize gas flow; check for cracks, heat discoloration, or blocked ports. They run roughly $18.63.

Replace if you see unstable arc, wandering kerf, or uneven consumable wear.

Always re-seat O-rings lightly lubricated and torque the cap to spec.

Part Numbers Reference for Powermax30 and 30/45 Cross-Compatibles

You’ll reference core Powermax30 parts by number—start with Electrode 220478, Nozzle 220480, and Retaining Cap 220483—for routine replacements.

Where you run both 30 and 30/45 systems, standardize on these shared consumables to simplify stocking and cut downtime.

For quick outfitting, select a starter kit that bundles these SKUs with compatible cartridges for cutting or gouging and SmartSYNC torches.

Powermax30 Core Parts

Core components define the Powermax30’s reliability, and the key consumables you’ll track by part number are the Electrode 220478, Nozzle 220480, and Retaining Cap 220483—each cross-compatible with Powermax30 and 30/45 platforms.

You’ll leverage these Powermax30 features for precise plasma cutting, keeping arc stability and cut quality consistent. Replace the 220478 electrode ($9.16) when starts degrade; swap the 220480 nozzle ($5.94) when orifice wear widens; retain shield integrity with 220483 to prevent misalignment.

- Visualize a crisp, concentric arc as a fresh 220480 nozzle snaps into place.

- Watch pilot starts recover immediately after a 220478 electrode change.

- Hear airflow seal correctly when the 220483 cap seats firmly.

Keep uptime high with the T30V hand torch assembly ($380.69) and lead replacement kit ($203.07), plus 14 available consumables.

30/45 Shared Consumables

Three high-rotation items tie the Powermax30 to the 30/45 platform: electrode 220478, nozzle 220480, and retaining cap 220483—each drop-in compatible for quick swaps and consistent arc quality.

Use these part numbers interchangeably to standardize spares, simplify bins, and gain shared benefits across both systems.

For gas flow stability, swap in swirl ring 220670. When you need edge shielding or drag cutting, fit deflector 220569.

These cross-family pieces preserve stack-up tolerances and consumable durability while minimizing changeover time.

Replacement guidance:

- Electrode 220478: change when pit depth nears 1 mm.

- Nozzle 220480: replace for widening kerf or angularity.

- Retaining cap 220483: inspect threads/seal; replace if heat-crazed.

- Swirl ring 220670: replace on cracks or gas-channel wear.

- Deflector 220569: replace if warped or eroded.

Starter Kits Overview

Although individual pieces are easy to source, starter kits bundle the right 15–45 A parts for Powermax30 and 30/45 users with matched part numbers for fast ordering and replacements.

You get curated consumables—no guesswork—so you maintain cut quality and minimize downtime.

HyAccess Gouging Starter Pack (15–45 A) and HyAccess Consumable Starter Kit (15–45A) deliver cross-compatible items whose part numbers mirror the Powermax30 and 30/45 catalogs, simplifying replacement calls.

- Open the kit: verify nozzle, electrode, swirl ring, shield part numbers against your Powermax30/30–45 lists.

- Use 15–45 A profiles as labeled; match amperage to torch settings for best life.

- Log kit part numbers; reorder exact replacements to preserve torch geometry.

- Count bulk quantities; calculate savings—starter kit benefits improve user experience and inventory control.

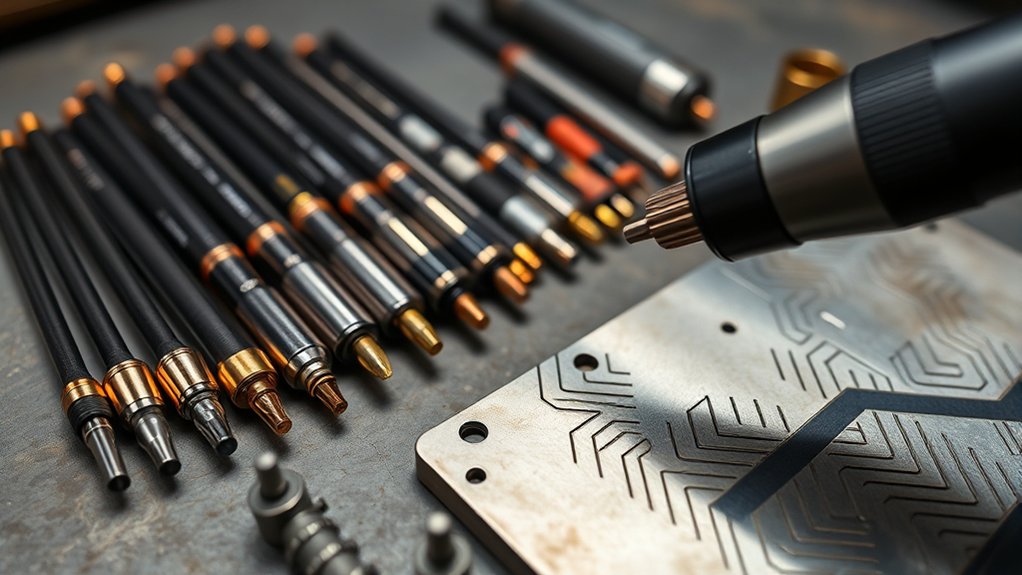

HyAccess Extended Consumables for Hard-to-Reach Cuts

For tight-access work, you’ll use HyAccess extended electrodes and nozzles that fit Powermax 30/30 XP and 45, specified by their HyAccess part numbers for assured compatibility.

Identify when to switch: choose the extended electrode/nozzle set when visibility and reach are limited to reduce torch repositioning and maintain cut quality.

Match each replacement by part number to your amperage and torch, then install per the service sequence to keep performance within spec.

What HyAccess Includes

When tight clearances block a standard torch, HyAccess extended consumables give you reach and control without re-fixturing. You get HyAccess features built for access, plus HyAccess benefits like faster setups with SmartSYNC compatibility and fewer fixture changes.

Each component is precision-made for durability and tight-tolerance performance on Powermax systems, including Pro 30.

- HyAccess Extended Electrode — long-reach electrode for confined joints; match amperage to your Powermax Pro 30 chart; replace when pit depth exceeds spec to maintain arc stability.

- HyAccess Extended Cutting Nozzle — extended orifice for intricate profiles; choose the correct current rating; swap at the first signs of edge bevel or dross increase.

- HyAccess Extended Gouging Nozzle — improved sightline in recesses; select style for removal rate; replace when orifice enlarges.

- HyAccess Retaining/Shield Interface — maintains standoff in deep access; confirm SmartSYNC cap pairing; inspect threads and O-rings during every change.

When To Use

Even in cramped fixtures or recessed joints, switch to HyAccess extended consumables when a standard torch can’t maintain standoff or sightline.

Use them for tight brackets, recessed gussets, or inside corner pierces where access limits arc stability. The longer design preserves arc length, improving precision performance while minimizing torch tilt and rework.

Choose the Extended Electrode for narrow channels or deep cavities; pair it with the HyAccess Gouging Nozzle when removing welds or back-gouging in confined spaces.

You’ll reduce repositioning, keep your cutting techniques consistent, and speed cycle time. When replacing, match the extended nozzle and shield style to your process (cut vs. gouge) and your Powermax30 setup, confirming system compatibility across Hypertherm platforms.

Swap worn parts proactively to maintain consistent kerf, smooth starts, and reliable pierces.

Part Numbers List

HyAccess extended consumables for the Powermax Pro 30 are identified by specific part numbers so you can order precisely what you need for tight-access cutting and gouging.

You’ll match parts to amperage (15–45 A) and torch task to maintain extended capabilities and cutting precision. Replace components as a set when wear affects arc shape or reach.

- Extended Electrode — part numbers span 15–45 A ratings; choose the amp-matched electrode to stabilize arc in deep or obstructed joints.

- Cutting Nozzle — select the orifice size and amp rating; correct part number maintains kerf control and heat balance in tight quarters.

- Retaining Cap — order the HyAccess-specific cap; it aligns stack-up and shields nozzle during close-in cuts.

- Gouging Nozzle — use the designated HyAccess gouge part; it improves visibility and material removal in confined geometries.

Pricing, Savings, and Bulk Starter Kits

Two clear paths help you control costs on Powermax30 consumables: buy individual part numbers as needed or step up to bulk starter kits for bundled savings. Use bulk pricing and savings strategies to match your duty cycle and stock policy. For precision cutting, electrodes run $9.16 each and nozzles $5.94; discounts apply on select lines—e.g., $3.90 off the Powermax 30/45 Electrode to $48.10. HyAccess Consumable Starter Kit (15–45A) combines multiple items at a lower blended rate, and orders over $300 ship free, improving landed cost per part.

| Item/Kit | Key Detail | Price/Benefit |

|---|---|---|

| Electrode (PN) | Unit price | $9.16 |

| Nozzle (PN) | Unit price | $5.94 |

| Electrode 30/45 (PN) | Promo price | $48.10 |

| HyAccess Starter Kit (15–45A) | Bundled mix | Reduced total |

| Cart ≥ $300 | Shipping | Free |

Tip: Plan replacements by burn rate. If you’re replacing electrodes/nozzles in pairs, kit up front; if your usage is light, buy singles and watch promos.

Torch Components, Replacement Kits, and Upkeep

While you can stretch consumable life with good technique, plan around the Powermax30’s core torch components and service kits so downtime stays near zero.

Prioritize assemblies and replacement kits first, then cycle consumables by cut quality. Consider torch upgrades only after baseline maintenance tips are locked in.

- 1) T30v hand torch assembly — $380.69 — replace when cable strain, gas leaks, or intermittent trigger faults persist after sub-assembly swaps.

- 2) Lead replacement kit, 15 ft — $203.07 — install when continuity tests show resistance drift; inspect strain reliefs and connector O-rings.

- 3) Torch handle replacement kit — $32.27 — use to restore ergonomics and trigger alignment; verify latch function with the safety trigger assembly ($16.46).

- 4) Main body replacement kit — $140.60 — swap if threads, gas passages, or seat faces are worn; pair with a new deflector ($18.63).

Keep consumables fresh: electrode ($9.16) changes when pit depth matches tip diameter; nozzle ($5.94) when orifice is oval or spatter-scarred.

Log part numbers, hours, and cut current to standardize intervals.

Cutting Guides, Safety Gear, and Helpful Accessories

You’ll choose a circle guide by package level—Basic ($163.05) or Deluxe ($271.39)—to match your cut radius needs and upgrade later without reworking your setup.

For safety, spec an operator face shield shade 8 ($73.26) and keep a clear window replacement on hand ($32.52); add Elkskin Welding Gloves ($39.11) and StarLite Safety Glasses ($1.65).

Protect and maintain the unit with the Powermax30 XP carrying case ($109.37) and an air filtration kit ($280.17) to stabilize cut quality and extend consumable life.

Circle Guide Options

Start with the circle-cutting fixtures: choose the Circle Cutting Guide Basic Package at $163.05 for standard radius work, or step up to the Deluxe Circle Cutting Guide at $271.39 for expanded diameter range and finer adjustment.

You’ll see circle guide benefits immediately: faster setup, repeatable arcs, and precision cutting on mild steel, stainless, and aluminum. Verify the kit’s compatibility with your torch body and standoff; note part numbers on the clamp, pivot pin, and radius arm for future replacements.

- Picture a rigid pivot pin anchoring your arc, the radius arm locking to the exact diameter.

- Visualize smooth carriage motion that prevents tip dive and oval circles.

- Imagine quick swaps between small and large radii without recalibration.

- See labeled components bagged for instant re-ordering when wear appears.

Essential Safety Gear

Safety first begins with part-confirmed gear that fits your Powermax workflow. Specify protective equipment by part and price so you can maintain compliance with safety standards and plan replacements.

Use the Operator Face Shield Shade 8 (part-confirmed, $73.26) for plasma arc glare and spatter; pair it with clear window replacements (part-confirmed, $32.52) to restore visibility when pitted or clouded. Inspect the shield lens each shift; replace at first haze, deep scratch, or heat distortion.

For guided cuts, select the Circle Cutting Guide Basic Package (part-confirmed, $163.05) for standard diameters, or upgrade to the Deluxe Circle Cutting Guide (part-confirmed, $271.39) for extended radius control and finer indexing.

Verify torch model compatibility before purchase, and record install dates to align preventive replacement with your shop’s inspection interval.

Carrying and Storage Accessories

Inventory discipline extends to how you carry, protect, and stage Powermax components. Choose carrying solutions and storage options that map to your job mix, budget, and replacement cadence.

For circular work, standardize on a guide and keep spare parts bagged, labeled, and dated. For PPE, track windows as consumables and replace at the first haze.

- Circle Cutting Guide, Basic Package — $163.05. Specify part no. from your supplier; tag kit contents and calibrate before first cut.

- Circle Cutting Guide, Deluxe — $271.39. Use when you need extended radius and finer adjustment; record accessory arm part numbers.

- Operator Face Shield Shade 8 — $73.26. Maintain a log for window change intervals.

- Clear Window Replacements — $32.52. Stock two per shield; replace on scratching.

Add a Powermax30 XP foam-lined carrying case — $109.37 — for protected transport.

Maintenance Intervals and Signs It’s Time to Replace

Someone running a Powermax Pro 30 should plan inspection and replacement at 20–30 operating hours, logging torch-on time per job to forecast consumable changes.

Use these maintenance tips to keep cuts consistent and minimize downtime: pull the shield, nozzle, and electrode on schedule and document wear by part number so you can reorder quickly.

Watch for replacement signs tied to cut quality. If you see increased dross, wider kerf, or arc instability, check the electrode first; heavy pitting or burn marks indicate immediate replacement.

Inspect the nozzle orifice under magnification; ovaling, chips, or micro-cracks degrade arc shape and demand a new nozzle. Excess bevel or double-arc starts also point to a worn nozzle.

Track usage patterns: short, frequent pierces wear nozzles faster; long continuous cuts stress electrodes.

Replace single components rather than running a mixed good/bad stack. Proactive swaps at 20–30 hours prevent cascading damage to adjacent consumables and keep performance on spec.

Upgrading to Hypertherm Cartridge Platform (SYNC) Options

While you’ve been managing a multi-piece stack (shield, nozzle, electrode) on the Powermax Pro 30, upgrading to the Hypertherm Cartridge Platform (SYNC) consolidates those parts into a single, color‑coded cartridge that installs with a torch adapter.

You’ll gain Hypertherm advantages like SmartSYNC auto‑setting of amperage/mode and end‑of‑life alerts that prompt timely replacements. With cartridge identification by color and label, you’ll reduce mix‑ups and streamline inventory.

- Visualize the adapter install: thread the SYNC torch adapter, seat the cartridge, and the torch recognizes process data automatically.

- Picture the color bands: yellow for drag cutting, gray for mechanized, and green for gouging—fast cartridge identification at a glance.

- See the control panel confirm: amperage/mode auto‑loads; you verify, test fire, and cut—no nozzle/electrode pairing required.

- Imagine the end‑of‑life icon: when it triggers, remove the spent unit and twist on the replacement cartridge, restoring cut quality.

For replacements, match the SYNC cartridge’s part-number family to your process and amperage; keep adapter and cartridge SKUs paired for consistent performance.

Ordering, Shipping, and Support Resources

Because genuine parts protect cut quality and torch life, order Powermax30 consumables and SYNC adapters/cartridges from authorized suppliers by exact part number to avoid compatibility issues.

Use the online catalog to verify each nozzle, electrode, swirl ring, shield, and retaining cap by SKU before checkout. Cross-check torch variant and amperage rating, then confirm quantities to match your replacement intervals.

Expect fast order processing; most in-stock items ship same day. Take advantage of free shipping on orders over $300 within the continental US—bundle high-use part numbers to minimize freight cost and downtime.

Track shipments via the supplier portal and set reorder points based on your average burn rate.

For customer inquiries, contact support with your torch model, serial number, and part numbers under review. Support can validate compatibility, suggest equivalent replacements, and assist with troubleshooting cut quality.

Review online product pages for specs, pricing, and inventory status to make an informed, parts-accurate purchase.

Frequently Asked Questions

How Do Ambient Temperature and Humidity Affect Consumable Lifespan?

Ambient effects shorten consumable lifespan: temperature fluctuations cause thermal shock, while humidity promotes oxidation and arc instability. You’ll inspect wear faster, adjust duty cycles, store parts desiccated, and schedule replacements sooner, cross-referencing part numbers to match electrodes, nozzles, and shields precisely.

Are There Recommended Air Compressor Settings for Optimal Consumable Wear?

Target 90–120 PSI air pressure at the torch, 6–8 CFM; studies show 1 PSI drop can cut life 3%. Match nozzle size (e.g., 220480) to orifice; replace filters regularly; verify regulator gauge accuracy and duty-cycle limits.

Can Counterfeit Consumables Be Identified Visually Before Installation?

Yes—you can often spot fakes via visual inspection. Check for counterfeit markings, inconsistent fonts, shallow laser etching, misaligned part numbers, poor plating, off-spec dimensions, and missing holograms. Compare to OEM drawings; reject and replace with verified P/Ns.

What Storage Conditions Prevent Oxidation of Electrodes and Nozzles?

Store parts in sealed desiccant bags at 20–25°C, <40% RH, away from ozone and salts. For electrode preservation and nozzle protection, use anodized trays, oil‑free handling, nitrogen purge cabinets, and rotate stock by part-number date codes to minimize replacements.

How Do Cutting Stainless vs. Aluminum Impact Consumable Selection?

You’ll pick different consumables: stainless needs fine-cut nozzles, slower cutting techniques, shorter life; aluminum favors wider orifices, higher speed. Match material thickness: thin=220941 nozzle/220842 electrode; medium=220930/220842; thick=220931/220842. Replace when orifice ovalizes or pit depth exceeds 1 mm.

Conclusion

You’ve got the roadmap: match your Powermax30 variant, verify part numbers, and swap before wear turns your cut into Achilles’ heel. Keep electrodes 220478, nozzles 220480, and retaining caps 220483 on hand; add swirl rings and HyAccess as your mission demands. Inspect every 20–30 hours, monitor arc starts and dross, and consider SYNC upgrades when workflows tighten. Order verified kits, leverage cross-compatibles where specified, and you’ll keep the arc true, like Odysseus’ bow—precise, repeatable, ready.