The 5/8-11 spindle thread on your angle grinder means it has a 5/8 inch diameter spindle with 11 threads per inch. This threading is standard in many grinders, including models like the Makita 9554NB. Ensuring a correct fit for your grinding wheels and attachments is essential to prevent wobbling and improve safety. You’ll need compatible flange nuts and disks with the right arbor size for peak performance. Discover more important details about fitting and compatibility here.

What Does the 5/8-11 Spindle Thread Mean for Your Grinder?

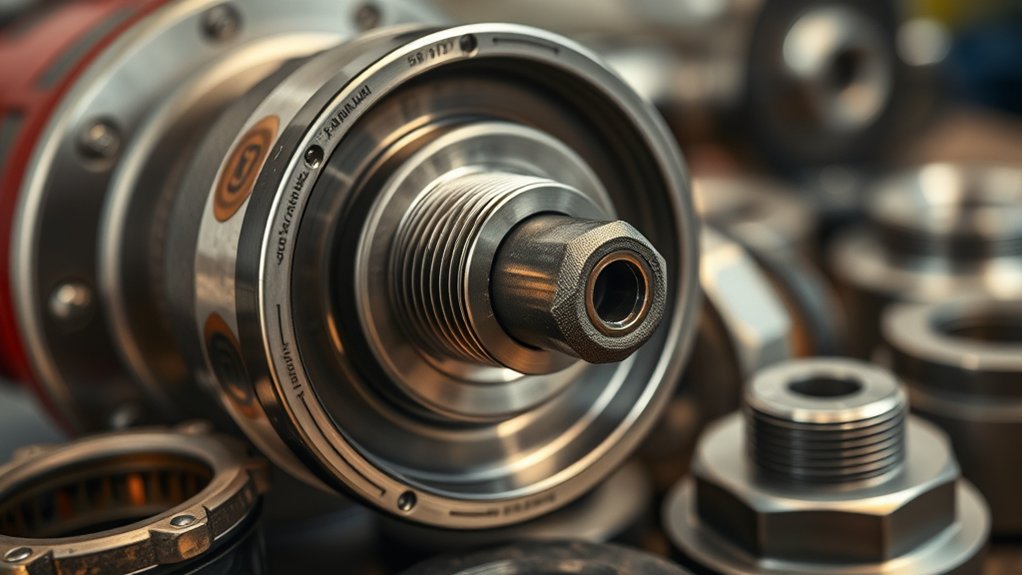

The 5/8-11 spindle thread is a vital specification for your angle grinder, indicating a spindle diameter of 5/8 inch with 11 threads per inch. This standard thread size is common in angle grinders ranging from 4-1/2 inches to 9 inches, ensuring compatibility with various grinding wheels. When you attach a grinding wheel, make sure that the flange nut is tightly secured. This prevents the disk from slipping or wobbling, which can lead to dangerous situations during operation. While adapters are available for using discs with different thread sizes on a 5/8-11 spindle, you must verify their compatibility and secure fit. Regularly inspect both the spindle threads and flange nut for wear or damage, as compromised components can jeopardize the grinder’s performance and your safety. Understanding the implications of the 5/8-11 spindle thread helps you make informed decisions for efficient, safe grinding.

Key Thread Sizes for Common Grinders and Their Implications

Understanding the 5/8-11 spindle thread is just one part of the broader picture when it comes to angle grinders. Recognizing key thread sizes helps you avoid compatibility issues and guarantees safe operation. Here are essential points to take into account:

- The 5/8-11 spindle thread is standard on many common grinders, like the Makita 9554NB.

- It’s important to match the flange nut and inner disc flange with the spindle thread to secure grinding wheels effectively.

- Using disks that don’t fit the 5/8-11 thread can lead to dangerous wobbling.

- Different bore sizes require appropriate adapters to prevent equipment damage.

- Mixing thread sizes, such as using a 5/8-11 disk on a different size spindle, can create significant safety hazards.

Choosing the Best Disks for 5/8-11 Spindles: A Step-by-Step Guide

Selecting the right disks for your 5/8-11 spindle is essential for achieving ideal performance and safety while using an angle grinder. First, verify the disk has a compatible 5/8-11 arbor hole to fit securely onto your grinder’s threaded spindle. Next, choose the disk type based on your task; for instance, a cutoff wheel is perfect for metal cutting, while a grinding disc excels in material removal. Pay attention to grit size: finer grits (80-120) yield smooth finishes, while coarser grits (36-60) are better for heavy-duty work. Always pair your disk with a flange nut that matches its specifications to prevent slipping and guarantee safe operation. Regularly inspect your disks for wear; damaged or worn disks can compromise safety and should be replaced promptly. Following these guidelines will enhance your grinding experience and keep you secure during use.

How to Ensure Compatibility With Flanges and Disks

Achieving ideal performance with your angle grinder hinges not just on choosing the right disks but also on verifying compatibility with the flanges. Here’s what you need to take into account:

- Always check that the flanges are designed for 5/8-11 spindle threads to prevent wobbling.

- Confirm the disk’s arbor hole matches the 5/8-11 thread for a secure fit.

- Ascertain proper engagement of the flange nut with the disk; tighten it securely to avoid movement.

- Some disks may have a 7/8 arbor hole, compatible with 5/8-11 spindles when used with suitable flanges.

- Regularly inspect both flanges and disks for wear or damage to maintain safety.

What to Do If Your Angle Grinder Attachments Don’t Fit?

When you find that your angle grinder attachments don’t fit, it’s important to start by verifying the spindle thread size, as this varies between models. Common sizes include 5/8-11 or M10, so confirm yours first. If there’s a mismatch, consider using spindle thread adapters to bridge the gap, allowing your attachments to fit securely.

Next, inspect the flange nut and inner disc flange; mismatched components can lead to unsafe operation. Verify that your cut off wheel or grinding disc has the correct bore size—commonly 7/8 for 5/8-11 grinders—to prevent wobbling and potential damage.

Lastly, regularly check for wear or damage on both the attachments and the grinder’s spindle. This vigilance is vital for maintaining compatibility and safety during use. By following these steps, you can guarantee a secure and effective operation of your angle grinder attachments.

Frequently Asked Questions

What Is a Spindle on an Angle Grinder?

A spindle on an angle grinder is a threaded shaft that drives attachments. Spindle types, materials, and dimensions vary, so verify proper maintenance and compatibility for peak performance and safety during grinding tasks.

What Is the Thread on an Angle Grinder?

The thread on an angle grinder varies by model, typically featuring common thread types like 5/8-11, M10, or M14. Ensuring thread compatibility with accessories is essential for safety and ideal performance in your tasks.

What Is a Spindle Lock on an Angle Grinder?

“A stitch in time saves nine.” A spindle lock on an angle grinder secures the spindle using a locking mechanism, enhancing safety features and ensuring tool compatibility, allowing you to change disks efficiently without risk.

What Is the Purpose of Using Proper Flange Size on a Grinder?

Using the proper flange size guarantees secure installation, prevents vibration, and enhances cutting stability. Flange compatibility with your grinding wheel and consideration of flange materials are essential for ideal performance and safety during operation.

Conclusion

In conclusion, understanding the 5/8-11 spindle thread is essential for maximizing your angle grinder’s performance. It’s the difference between a smooth, efficient operation and frustrating compatibility issues. While the right disks can enhance your work, mismatched flanges can lead to setbacks. By ensuring compatibility and selecting the best attachments, you can transform your grinding tasks from tedious to seamless. Embrace the precision of the 5/8-11 thread, and elevate your grinding experience to new heights.