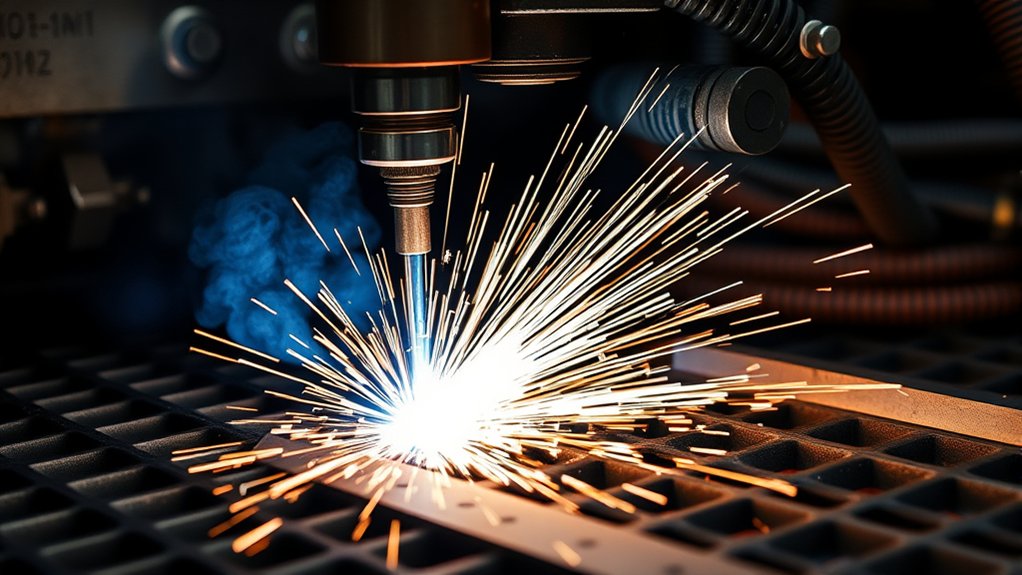

You’ll choose plasma cutting gas based on material, thickness, cut quality, and cost. Compressed air suits mild steel to about 1 inch, while oxygen improves edge quality on thicker carbon steel. For stainless and aluminum, nitrogen is common up to roughly 3 inches; beyond that, argon-hydrogen boosts speed and finish. Match gas purity, flow, and torch ratings to standards, and respect ventilation and PPE requirements. But which setup actually optimizes your shop’s workflow?

Compressed Air

One gas stands out for most plasma cutting tasks: clean, dry compressed air. As a versatile plasma gas, it supports cutting mild steel, stainless, and aluminum up to 1 inch (≤25 mm) with effective cut quality at lower cost.

To meet performance and safety standards, you must maintain a clean air supply. Use a dedicated air compressor sized for flow and pressure, plus a refrigerated dryer and staged filters to remove dust, oil mist, and moisture that destabilize the arc and erode consumables.

Compressed air minimizes operational costs because you don’t buy separate gases and it excels in low current cutting. However, expect some nitriding and oxidation on cut edges, which can reduce weldability.

Mitigate by adjusting parameters, performing post-cut edge prep, or selecting alternate process gas when codes require pristine weld interfaces. Verify dryness (e.g., pressure dew point ≤ +3°C) and filter ratings routinely, and document maintenance to guarantee consistent, compliant results.

Oxygen

When mild steel cut quality and speed are your priority, move from shop air to oxygen plasma. You’ll get the industry-standard result on mild steel: crisp edges, narrow kerf, and maximum travel speed.

Oxygen enhances kerf ejection by producing a finer spray of molten metal, delivering superior cut quality up to 1-1/4 in (≤32 mm) for demanding industrial applications. Pair oxygen with clean, dry air as a shielding gas to protect the arc and plate surface, improving performance and reducing contamination.

- Verify gas purity and flow per manufacturer specs; contamination degrades cut quality and increases dross.

- Use correct current, standoff, and swirl ring orientation to stabilize the arc and optimize kerf ejection.

- Expect higher operating cost; oxygen shortens consumable parts life—plan for inventory and timely changeouts.

- Implement ventilation, leak checks, and oxygen-compatible fittings to meet safety standards and prevent fires in plasma cutting cells.

Nitrogen

When you need high-current performance, nitrogen supports stable arcs for cutting stainless and aluminum, even on sections approaching 3 in.

You’ll also reduce downtime because nitrogen can extend electrode and nozzle life, often past 1,000 starts when operated within manufacturer duty-cycle and cooling limits.

Follow OEM gas specifications and pair nitrogen with approved secondary gases to maintain cut quality and protect consumables.

High-Current Performance

Although it costs more than shop air, nitrogen excels in high-current plasma cutting where precision and durability matter. You’ll leverage stable arc density to process sections up to 3 inches with excellent cut quality, while maintaining tighter tolerances and lower dross.

In industrial settings, nitrogen supports sustained high-current duty cycles, extending consumable life by reducing oxidation and thermal shock to electrodes and nozzles. Pairing nitrogen with carbon dioxide or air can boost cutting speed on thicker cross-sections, provided your system meets manufacturer specifications and safety requirements.

- Verify gas purity and flow rates to ISO/ASTM guidance for consistent precision.

- Match nozzle orifice to amperage to prevent double-arcing and tip wear.

- Use shield gas synchronization to stabilize kerf geometry.

- Monitor duty cycle, coolant temperature, and torch standoff to protect components.

Stainless and Aluminum

Building on nitrogen’s strength at high current, you’ll get standout results on stainless steel and aluminum where oxidation control and edge integrity matter.

Choose nitrogen for plasma cutting non-ferrous metals when you need high-current capacity, fast travel, and clean cuts up to about 3 inches. It maintains arc stability, delivers consistent cut quality, and limits nitriding or heat tint when you follow manufacturer amperage, standoff, and gas flow specifications.

Use a nitrogen gas combination—typically nitrogen with carbon dioxide or air—when you’re processing thicker sections and require improved dross removal and cooling.

While nitrogen can yield fair results on mild steel, reserve it primarily for stainless steel and aluminum to meet quality standards.

Verify torch duty cycle, confirm leak-free fittings, and monitor electrode/nozzle wear to protect consumable life and process safety.

Extended Consumable Life

Durability defines nitrogen-based plasma cutting, with stable arcs that reduce electrode and nozzle erosion and routinely exceed 1,000 starts per set.

You’ll see longer consumable life because nitrogen resists oxidation, keeps arc density consistent, and preserves cut quality on stainless steel.

In high-current plasma, nitrogen sustains energy transfer for thicker materials without premature wear.

Pair nitrogen with air plasma as a secondary gas to balance performance and operational costs while maintaining clean edges and tight kerf geometry.

- Specify nitrogen purity per manufacturer guidance; verify flow, pressure, and swirl ring alignment before each shift.

- Match nozzle and electrode to high-current plasma ratings to prevent overheating and micro-cracking.

- Use nitrogen/air secondary gas for stainless steel to stabilize arc and reduce dross.

- Track starts-per-set and cut length to forecast consumable life and budget.

Argon-Hydrogen Mixtures

Argon–hydrogen mixtures—most commonly 65% argon and 35% hydrogen—deliver the hottest plasma jet for cutting thick stainless steel and aluminum over 1/2 inch. You’ll use argon-hydrogen mixtures in plasma cutting when you need maximum cutting capability on high-alloy materials and demand cleaner and smoother cuts with minimal heat tint.

Argon’s inert behavior stabilizes the arc, while hydrogen raises enthalpy, improving cut quality and preventing contamination so finished surfaces appear polished.

Argon stabilizes the arc; hydrogen boosts enthalpy for cleaner, polished, contamination-free cuts.

Follow manufacturer duty-cycle limits and ventilation requirements. Expect potential jagged dross on the lower edge at high amperage; mitigate by refining standoff, travel speed, and current, and guarantee nozzle alignment meets spec.

When emissions control and edge finish are priorities, pair nitrogen as a shield gas to further stabilize the plume and reduce fume generation.

Verify gas purity, leak-test fittings, and ground per IEC/ISO safety standards. Purge lines before ignition, monitor torch cooling, and document parameters for repeatability and compliance.

Gas Selection by Metal and Thickness

You’ll select gas by matching metal and thickness to proven process standards.

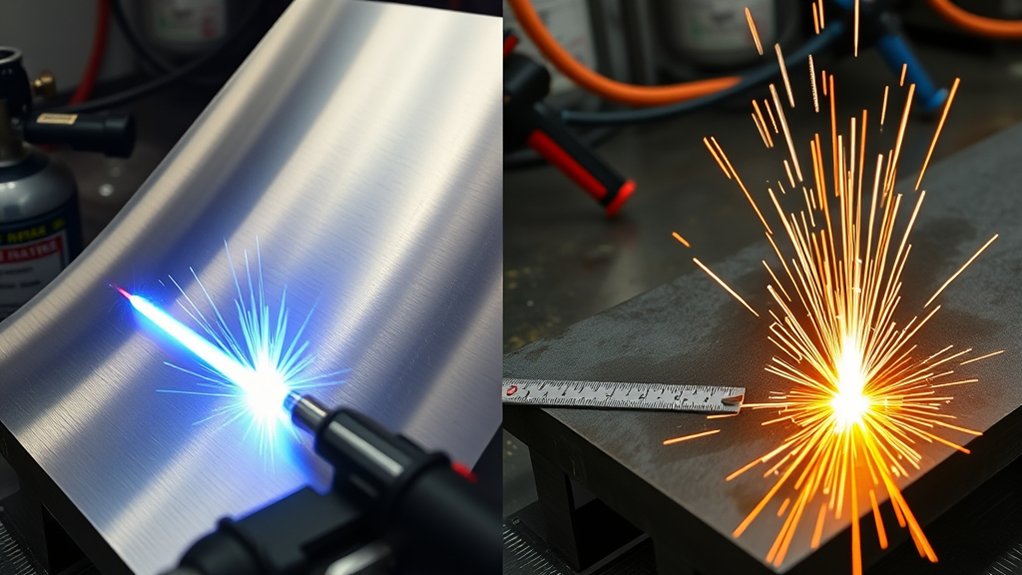

For mild steel, use compressed air up to about 1 inch, then switch to oxygen for carbon steel up to 1¼ inches to maximize cut speed and quality; avoid oxygen on stainless or aluminum.

For stainless and aluminum, choose nitrogen up to roughly 3 inches, and move to a 65% argon/35% hydrogen mix beyond ½ inch for cleaner, straighter cuts while observing equipment ratings and ventilation requirements.

Mild Steel Choices

For mild steel, prioritize oxygen for the primary plasma gas because it delivers the fastest speeds and cleanest edges up to about 1-1/4 in. You’ll get superior cut quality and reliable kerf geometry, making oxygen the industry-standard gas for cutting.

Pair oxygen with compressed air as a secondary gas to balance cost and cutting performance; this gas mixture maintains edge integrity while minimizing consumable spend. If you switch to compressed air plasma cutting alone, expect acceptable results on mild steel to roughly 1 in, though edges may be slightly rougher.

Nitrogen works, but it tends to leave more dross, so it’s a compromise.

- Verify gas purity and flow per OEM specs.

- Ground work securely; prevent arc blow.

- Use correct nozzle orifice and amperage.

- Monitor edge bevel and dross to adjust speed.

Stainless/Aluminum Options

Two gas families cover most stainless and aluminum work: nitrogen-based plasmas for thin-to-medium sections and argon–hydrogen blends for thick plate.

For cutting stainless steel and cutting aluminum up to 1/2 inch, specify nitrogen plasma to achieve excellent cut quality and long consumable life. You can mix nitrogen with carbon dioxide or air to enhance cutting speed while maintaining edge integrity.

When sections exceed 1/2 inch, switch to a 65/35 argon-hydrogen mixture; it delivers smooth kerfs and polished surfaces with stable arc density.

Avoid oxygen plasma on these alloys; it degrades consumable life and compromises finishes, though it’s appropriate for mild steel.

Compressed air is economical for general cuts up to 1 inch, but expect reduced performance and finish on thicker nonferrous plate.

Thickness-Based Gas Picks

One rule governs plasma gas selection: match the gas to the metal and its thickness to balance speed, edge quality, and consumable life.

For thin work under 1/2 inch, use compressed air across mild steel, stainless steel, and aluminum to maximize versatility and cost control.

Step up to oxygen on mild steel up to 1¼ inches for fast plasma cutting and crisp edges; don’t use oxygen on stainless steel or aluminum.

For greater material thickness, nitrogen maintains cut quality and extends consumable life, especially on stainless steel and aluminum up to 3 inches.

When stainless or aluminum exceeds 1/2 inch, an argon-hydrogen mixture (65/35) delivers smooth, dense cuts at higher operating cost.

- Verify material thickness with calibrated gauges

- Follow torch manufacturer gas pressure specs

- Use dry, clean gas to protect cut quality

- Monitor arc voltage and kerf for tuning

Equipment and Cost Considerations

Several equipment and cost factors determine which plasma-cutting gas you should run, starting with machine compatibility—your torch, power supply, and gas console must be rated for the specific gas (air, nitrogen, oxygen, argon-hydrogen) and pressure/flow standards.

Verify gas compatibility for your plasma cutting equipment before gas selection; mismatches reduce cut quality and violate safety and warranty requirements.

Verify plasma gas compatibility first—mismatches degrade cut quality and can void safety and warranty compliance.

Compressed air minimizes operational costs and suits many cutting materials, but it demands dry, clean supply air; schedule maintenance for filters, dryers, and lines to protect consumable life.

Performance gases improve edge quality and speed, especially on thicker materials, yet they raise cost per cut and may require upgraded consoles and regulators.

Plan for cylinder logistics, regulators, and leak testing. Track consumable life by gas type and amperage to determine true cost per part.

When evaluating options, balance upfront hardware, gas price, maintenance burden, and throughput targets to meet process standards and budget.

Frequently Asked Questions

What Gas Is Best for Plasma Cutting?

You’ll pick plasma cutting gases by material and thickness: oxygen for carbon steel, nitrogen benefits stainless/aluminum, argon-hydrogen for thick nonferrous. Consider ideal gas choices, gas mixtures explained, argon vs oxygen performance factors, cost comparisons, gas purity importance, and safety measures, including ventilation.

Does a Plasma Cutter Use Any Gas?

Yes—a plasma cutter uses gas. Measure twice, cut once. Use a plasma cutter basics gas selection guide; consider cutting speed factors, gas flow rate, efficiency comparison, nozzle types, cutting thickness considerations. Follow safety precautions, apply maintenance tips, and troubleshoot issues methodically.

What Is F5 Gas for Plasma Cutting?

F5 gas is a nitrogen–hydrogen blend for plasma cutting, typically about 95% nitrogen and 5% hydrogen. You’ll use it primarily for stainless steel cutting where you want bright, oxide-free edges and improved finish on thin to mid-thickness plate. Consider disadvantages (cost), equipment compatibility, safety, and storage. Compare F5 gas vs. nitrogen or compressed air for your application. Verify suppliers, applications, and standards-compliant handling.

Will a 20 Gallon Air Compressor Run a Plasma Cutter?

Yes—if it delivers 4–5 CFM at 90 PSI. That spec supports 1-inch cutting thickness limits for many plasma cutter brands. Mind duty cycle effects, compressor capacity, power supply needs, portability considerations, air compressor types, usage efficiency, and compressor maintenance tips.

Conclusion

You’ll choose plasma gases by metal and thickness to balance cut quality, speed, and cost. Air handles mild steel to about 1 in; oxygen sharpens thicker steel; nitrogen suits stainless and aluminum to ~3 in; argon-hydrogen excels beyond that. One telling data point: optimized gas selection can cut bevel angle by 30–50%, reducing secondary grinding. Follow manufacturer specs, verify gas purity, maintain regulators and hoses, and perform leak checks to uphold safety, consistency, and standards compliance.