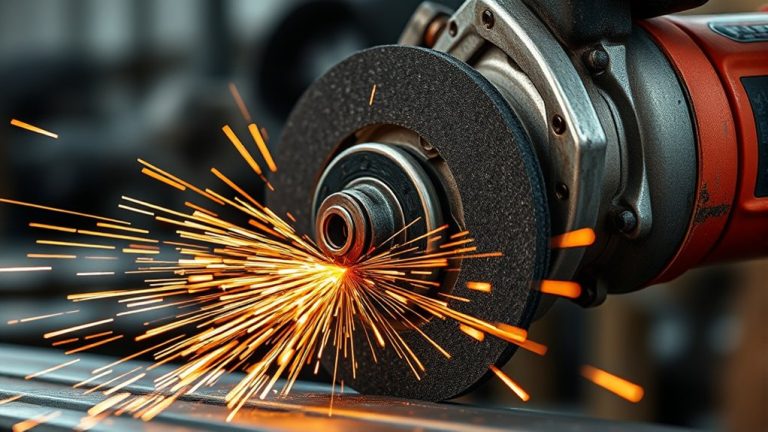

Angle grinder amperage measures the electrical current drawn by the tool, essential for its power and performance. Higher amp ratings lead to better torque, especially for heavy-duty tasks. For most projects, you’ll want at least 6 amps, with 6.7 amps ideal for heavier applications. Picking the right amperage guarantees efficiency and prevents stalling during use. Understanding these specifications will help you choose the best grinder for your needs, and there’s more to take into account for peak tool selection.

What Is Angle Grinder Amperage and Why Does It Matter?

Angle grinder amperage is a crucial specification that directly affects the tool’s performance and efficiency. The amperage rating indicates the electrical current drawn by the tool, and a higher amp rating typically leads to increased torque, important for heavy-duty tasks. For professional use or serious DIY projects, a minimum of 6.0 Amps is recommended for a 4-1/2 inch grinder, guaranteeing it doesn’t stall under load. High-performance angle grinders often exceed 6.5A, allowing them to maintain disc speed during demanding applications. Understanding amperage is essential for selecting the right grinder for specific projects, as it guarantees your power tools can effectively handle the material thickness and type. Using a grinder with insufficient amperage can lead to tool bogging or failure during operation, compromising safety and efficiency. Choosing the right amperage rating empowers you to achieve ideal results in your projects.

How Angle Grinder Amperage Affects Performance and Efficiency

When selecting an angle grinder, understanding how amperage influences performance and efficiency is essential. The amperage rating directly correlates with the power and torque a grinder can deliver. Higher amperage tools, typically above 6 Amps, are vital for heavy-duty tasks as they prevent stalling and maintain consistent RPMs during demanding cutting jobs.

| Amperage (Amps) | Power (Watts) | Recommended Use |

|---|---|---|

| 6.0 | 720-800 | Light to moderate tasks |

| 6.7 | 800-850 | Heavy-duty applications |

| 8.0+ | 960+ | Industrial and fabrication |

A grinder with 6.7 Amps efficiently tackles tougher materials, ensuring aggressive cutting and longevity under stress. Prioritizing higher amperage tools means you enhance performance and efficiency, especially when facing dense or thick materials.

Ideal Amperage Ratings for Common Angle Grinder Tasks

Selecting the right amperage rating for your angle grinder is vital for achieving excellent results in various tasks. For general DIY projects, aim for a grinder with at least 6 Amps and 10,000 RPM to guarantee efficient cutting or grinding. If you’re tackling heavy fabrication work, choose an angle grinder rated at 6.7 Amps or higher; this provides the necessary torque and speed for demanding applications. Professional-grade grinders often exceed 6.5 Amps, preventing bogging down under heavy loads and maintaining consistent performance. While lower amp grinders (below 6 Amps) may suit lighter tasks like polishing or finishing, they can struggle with tougher materials. Understanding the specific amperage needs of your task will help you select the right tool for the job, maximizing power consumption and promoting safety. Remember, matching the ideal amperage ratings to your projects is essential for superior results.

Comparing Low vs. High Amp Angle Grinders

Understanding the differences between low and high amp angle grinders can considerably impact your project’s success. Low amp grinders, typically drawing 2 to 6 amps, excel at light-duty tasks like small metal cutting. In contrast, high amp models, starting at 6.5 amps and reaching up to 15 amps, are suited for heavier applications requiring greater power and torque.

| Feature | Low Amp Grinders |

|---|---|

| Amperage Range | 2 to 6 amps |

| Ideal Use | Light-duty tasks |

| Performance | Lower torque |

| Best RPM | Varies, generally lower |

| Material Thickness | Thin materials |

| Feature | High Amp Grinders |

| Amperage Range | 6.5 to 15 amps |

| Ideal Use | Heavy-duty tasks |

| Performance | Higher torque |

| Best RPM | 10,000 to 12,000 RPM |

| Material Thickness | Dense or hard materials |

Choose wisely based on your project’s demands.

The Link Between Amps, Watts, and RPM

The relationship between amps, watts, and RPM is vital for maximizing the performance of your angle grinder. Amperage, or running amps, indicates the electrical current drawn by the tool; higher amps deliver greater torque, enhancing performance under load. Wattage, calculated as watts = amps x volts, is important too. For instance, a grinder with 6.7 amps typically translates to about 800-850 watts in a 120V system, directly affecting cutting and grinding capabilities. RPM measures the spindle speed; higher RPM values (10,000-12,000) are ideal for aggressive cutting, while lower RPM (7,000-8,500) offers better control for grinding tasks. Selecting an angle grinder with the right power ratings guarantees you meet specific project demands. Understanding how amps, watts, and RPM interconnect allows you to choose the best tool for your needs, assuring both efficiency and safety in your work.

How to Pick the Right Amperage for Your Projects

To pick the right amperage for your projects, start by evaluating the specific requirements of the tasks at hand. Evaluate the tool specifications, focusing on the amperage needed for the material thickness and hardness you’ll encounter. This guarantees you select an angle grinder that delivers the performance you need without sacrificing efficiency.

Assess Project Requirements

Choosing the right amperage for your angle grinder is essential for achieving peak performance in your projects. Assess your project requirements by considering the material thickness and hardness. For light DIY tasks, a grinder with a minimum of 6 amps is sufficient. However, heavy fabrication work often demands grinders rated at 6.7 amps or higher.

| Project Type | Recommended Amperage |

|---|---|

| Light DIY Projects | 6 Amps |

| Heavy Fabrication Work | 6.7 Amps or Higher |

| Precision Cutting | Lower Amperage |

| Aggressive Cutting | Higher Amperage |

Always refer to the manufacturer’s specifications to guarantee you select the appropriate amperage for your specific cutting needs.

Evaluate Tool Specifications

When considering the right amperage for your angle grinder, it’s vital to align the tool’s specifications with your project demands. For general DIY projects and cutting tasks, aim for a minimum of 6 Amps. If you’re tackling heavy-duty applications like metal fabrication or welding, opt for grinders rated at 6.7 Amps or higher to prevent stalling. Additionally, check the RPM rating; high-performance models should exceed 10,000 RPM for peak speed and efficiency. Always match the grinder’s amperage to the material and task; higher amps provide more torque, important for thicker materials. Understanding these specifications guarantees you select the right power tools to achieve your desired results without bogging down during operation.

Debunking Common Misconceptions About Angle Grinder Amperage

While many assume that higher amperage in angle grinders guarantees superior performance, this belief overlooks several essential factors that influence a tool’s effectiveness. Amps do indicate torque and the ability to handle demanding tasks, but they aren’t the sole determinants of performance. The grinder’s RPM, build quality, and motor efficiency are equally important in evaluating how well it’ll perform. A common misconception is that low amp grinders can tackle heavy-duty jobs; they often falter under pressure, risking damage or failure. Additionally, understanding the relationship between amps, watts, and volts is significant. For instance, a 6.7 Amp grinder typically translates to around 800-850 Watts, making it versatile for various tasks. When you’re ready to choose the right angle grinder, remember that a balance of specifications, not just amps, is key to revealing true performance in your power tools.

Frequently Asked Questions

Is a Higher Amp Grinder Better?

Yes, a higher amp grinder typically enhances performance, offering better motor strength and cutting speed. It improves tool efficiency while managing heat generation, ensuring durability factors align with your power requirements for demanding tasks.

What Is a Good Amperage for an Angle Grinder?

For angle grinder performance, aim for 6 to 15 Amps. Consider your usage frequency, material types, and safety. Selecting the right grinder with ideal amperage guarantees you meet tool power requirements without compromising efficiency.

How Many Amps Is 5000 Watts at 240 Volts?

To calculate, 5000 watts at 240 volts equals about 20.83 amps. Confirm your equipment matches this amperage for ideal tool performance, considering voltage, wattage conversion, and safety guidelines to maintain electrical efficiency and compatibility.

Does Higher Amps Mean More Power?

Yes, higher amps generally mean more power. Increased amperage impacts motor efficiency, enhances cutting speed, improves tool durability, reduces heat generation, and optimizes energy consumption, greatly elevating your user experience based on project requirements.

Conclusion

In the grand scheme of angle grinders, you might think higher amperage always means better performance. Ironically, choosing the right amperage doesn’t just involve picking the biggest number you see. Instead, it’s about matching the tool’s capabilities with your specific tasks. By understanding amperage and its implications, you’ll guarantee your projects run smoothly and efficiently. So, next time you’re tempted to go big, remember: sometimes, less really is more. Choose wisely, and your work will thank you.