The angle grinder flange is a significant component for securing grinding and cutting discs. It’s important to fit it correctly; the raised hub must face the disc for grinding; switch to the flat side for cutting. Always check compatibility and orientation before use to enhance safety and prevent accidents. Regular inspections for wear and damage are necessary. To optimize performance and avoid common mistakes, understanding different flange types and troubleshooting tips is important. You’ll uncover more significant insights further on.

What Is an Angle Grinder Flange and Its Purpose?

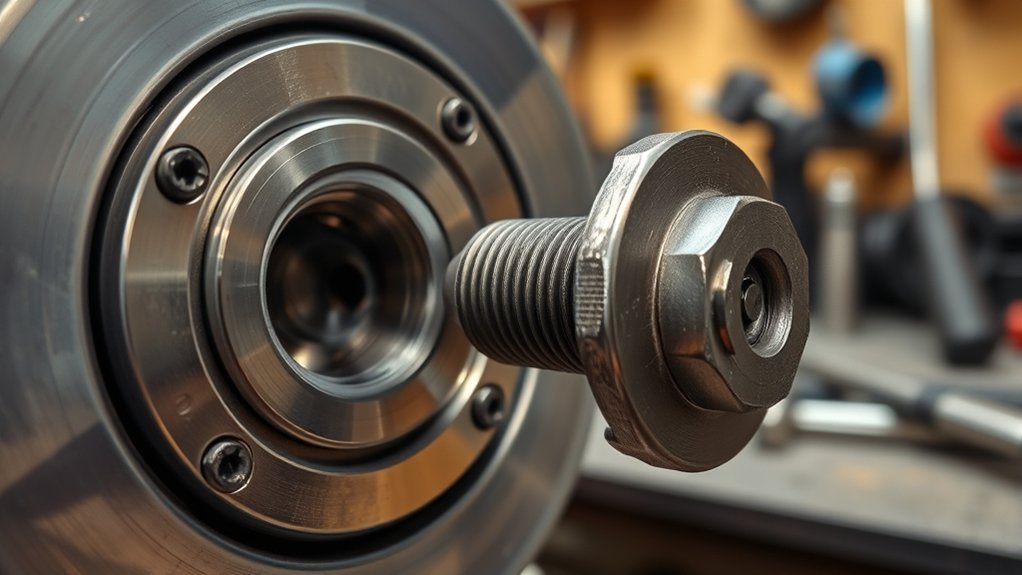

An angle grinder flange is an essential component that secures accessories like grinding and cutting discs to the spindle of your angle grinder. It comes in two types: a top flange, featuring a raised center hub for grinding discs, and a flat side for cutting discs. This design guarantees proper fitting based on the accessory you’re using. Flanges accommodate both 5/8 inch and 14mm center-hole accessories, enhancing compatibility across various angle grinder models.

The proper orientation of the flange is critical; incorrect usage can lead to accidents or damage to your equipment. A well-designed flange allows for easy release and secure fitting, which is fundamental for maintaining tool performance and safety. By understanding the role of the flange, you empower yourself to utilize angle grinders effectively, guaranteeing your work is not only efficient but also safe. This knowledge liberates you from potential mishaps and enhances your mastery of the tool.

How to Safely Fit Your Flange

Fitting your flange correctly is vital for safe and effective operation of your angle grinder. Start by consulting your flange compatibility checklist to confirm the right flange for your specific grinder model. When using grinding discs, position the raised hub of the top flange to secure the fit. For thinner cutting discs, flip the flange to utilize the flat side, preventing slippage. Remember to reverse the flange anytime you switch disc types, which maintains safety and clamping pressure. Verify proper alignment by tightening the flange adequately; loose attachments can lead to dangerous situations. Regularly inspecting your flanges for wear and damage is essential to guarantee they provide the necessary support during operation. By following these flange fitting techniques, you can enhance your angle grinder’s safety and performance, empowering you to work with confidence.

Avoiding Common Flange Mistakes: Key Tips for Safety and Efficiency

While using an angle grinder, avoiding common flange mistakes is essential for maintaining safety and efficiency. First, verify you conduct regular disc compatibility checks; remember that grinding discs require a raised hub, while cutting discs need a flat side for proper fitting. When switching between different types of discs, always reverse the flange as needed to secure it properly, preventing potential accidents.

Implement flange maintenance tips by inspecting for wear or damage before each use. A compromised flange can lead to dangerous situations, so make this a routine practice. Additionally, familiarize yourself with the threading of your angle grinder to verify compatibility with the flange. Finally, never overlook the importance of securing the flange properly; a loose fit can result in disc detachment, posing serious injury risks. By following these guidelines, you’ll enhance both your safety and efficiency during operations.

Types of Flanges: Threaded vs. Threadless

Understanding the types of flanges is vital for maximizing your angle grinder’s performance. Flanges come in two primary types: threaded and threadless. Threaded flanges have internal threads, making them secure for high-torque applications, while threadless flanges allow for quick, tool-free accessory changes. This distinction is significant for selecting the right flange based on your specific tasks.

When considering a flange materials comparison, make sure you choose materials that enhance durability and compatibility with your angle grinder model, as outlined in the flange compatibility guide. Proper flange maintenance tips, such as regular inspections and cleaning, will help prolong the lifespan of both flange types, guaranteeing safety and efficiency during operation. By understanding these differences, you can make informed decisions that lead to peak performance and a safer working environment.

Troubleshooting Flange Issues: Quick Fixes and Tips

Proper flange selection is just the beginning; ensuring they function correctly is equally important. Regular flange maintenance tips can prevent compatibility issues and enhance safety. Start by checking the orientation—ensure the raised hub faces the disc. If you encounter a tight flange, use an adjustable wrench on the cutaway sides for easier release.

| Problem | Quick Fix |

|---|---|

| Flange too tight | Use adjustable wrench on cutaway sides |

| Wrong flange type | Match flange to specific disc type |

| Worn or damaged flange | Regularly inspect and replace as needed |

| Lost flange | Consider a universal flange for 7/8 center-hole accessories |

If you face flange replacement options, always prioritize compatibility with your specific angle grinder. Keeping a keen eye on these aspects will not only enhance your tool’s performance but also liberate your grinding experience.

Frequently Asked Questions

Why Are 9 Inch Grinders Banned?

9-inch grinders are banned due to safety regulations addressing their torque and kickback risks. Tool limitations make them harder to control, prompting the adoption of safer grinder alternatives that guarantee better user safety and efficiency.

What Is the Purpose of Using Proper Flange Size on a Grinder?

Using the proper flange size guarantees flange compatibility, enhancing grinder safety and tool maintenance. This prevents accidents by securely holding discs, reducing vibrations, and optimizing performance, ultimately empowering you to work confidently and efficiently.

Can I Turn My Grinder Into a Polisher?

Yes, you can turn your grinder into a polisher by using appropriate polisher attachments and buffing pads. Make certain the RPM is suitable for surface finishing to avoid damaging materials, and secure everything properly for safety.

What Is a Backing Flange on a Grinder?

A backing flange on a grinder secures discs, ensuring stability and safety. Use proper materials and follow flange installation tips diligently. Prioritize grinder safety precautions to avoid accidents and enhance your grinding experience.

Conclusion

In conclusion, understanding your angle grinder’s flange and backing nut is essential for peak performance and safety. By ensuring proper orientation and fit, you can prevent accidents that could be as catastrophic as a house of cards tumbling down. Remember to avoid common mistakes and choose the right flange type for your needs. With these insights, you’ll not only enhance efficiency but also prolong the lifespan of your tools. Stay safe and grind smart!