No-load speed in angle grinders is the maximum RPM achieved without any material resistance, typically ranging from 7,000 to 12,000 RPM. Under load, this speed drops due to material resistance, often falling to 7,000-8,000 RPM for tougher materials. The grinder’s torque plays a vital role, as higher torque models maintain RPM better during heavy use. Understanding these dynamics is essential for selecting the right tool for your project and optimizing performance. Explore further to gain deeper insights.

Understanding No-Load Speed: Its Importance for Efficient Angle Grinder Use

Understanding no-load speed is critical for maximizing the efficiency of your angle grinder. This term refers to the maximum RPM the grinder can achieve without any applied cutting or grinding force. Typically, you’ll find no-load speeds ranging from 7,000 to 12,000 RPM, which directly influences the tool’s suitability for various applications. Knowing the no-load speed allows you to assess its potential efficiency when tackling different materials. However, keep in mind that the operational speed often decreases due to material resistance, which can greatly affect performance. This discrepancy underscores the importance of matching your grinder’s no-load speed with the RPM ratings of the discs or blades you’re using. By understanding these factors, you can guarantee your angle grinder operates effectively, maximizing both productivity and safety in your projects.

Understanding RPM Ratings: How They Affect Performance Under Load

When you look at an angle grinder’s RPM rating, you’re examining its no-load speed, which indicates how fast the disc spins without any resistance. Under load, however, that speed decreases due to the material’s resistance, affecting cutting efficiency. Understanding this relationship is essential for selecting the right grinder for your specific tasks and ensuring peak performance.

No-Load Speed Defined

No-load speed, measured in revolutions per minute (RPM), is a critical specification that reflects an angle grinder’s maximum potential performance without the influence of material resistance. This benchmark provides insight into what the tool can achieve during cutting or grinding tasks. For instance, the Bosch GWS 6-100 S offers a no-load speed of approximately 10,000 RPM, which may drop to around 9,000 RPM or lower when engaged with material. Understanding this distinction between no-load speed and actual working speed is essential for effective tool selection. Utilizing a disc rated for a higher RPM than your grinder’s no-load speed can lead to safety hazards or tool failure, emphasizing the importance of matching capabilities to task requirements.

Impact of Load Conditions

The relationship between no-load speed and performance under load greatly impacts an angle grinder’s effectiveness during operation.

- A no-load RPM typically ranges from 10,000 to 12,000.

- Under load, actual RPM can drop, affecting efficiency.

- High torque models, rated above 6.5 Amps, maintain stability under load.

- Matching the RPM rating with accessory requirements guarantees safety.

When you’re cutting or grinding, understanding how RPM means on angle affects your work is vital. A high no-load RPM can lead to decreased performance under load, increasing wear on your disc. Selecting the right angle grinder based on its RPM rating and load capabilities optimizes both efficiency and safety, empowering you to tackle demanding tasks with confidence.

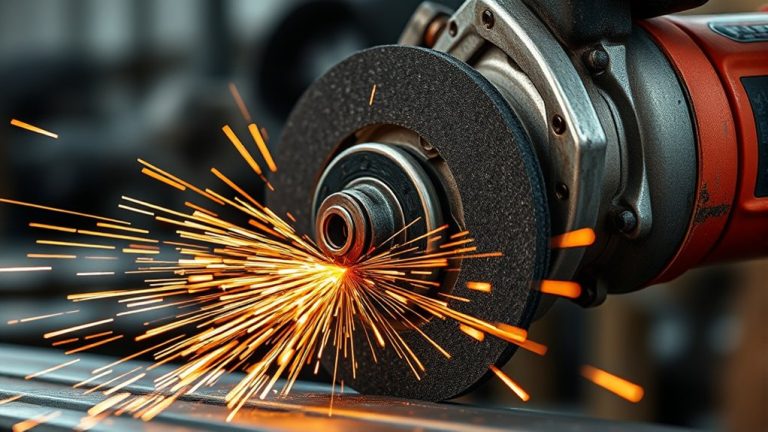

How Material Resistance Affects Your Grinder’s RPM During Use

Understanding how material resistance impacts your angle grinder’s RPM during operation is essential for achieving peak performance. When you engage your grinder, the material being cut or ground generates drag, greatly lowering the effective RPM. For instance, while your corded grinder may boast a no-load speed of 10,000 RPM, this can plummet to 7,000-8,000 RPM under heavy load, depending on the material’s hardness and thickness.

Higher torque models, particularly those rated at 6.7 Amps or more, excel at maintaining RPM under load. The interaction between the grinding disc and the material largely dictates this RPM drop. Softer materials result in less resistance, while harder materials lead to substantial reductions in effective speed. Recognizing these dynamics helps you select the right grinder and disc combination, ensuring efficient and safe material removal tailored to your specific tasks.

Choosing Accessories for No-Load and Working Speeds

When choosing accessories for your angle grinder, it’s essential to select discs that align with the tool’s no-load speed rating for peak performance. Understanding the compatibility factors, including minimum RPM requirements, guarantees safe operation during various tasks. Matching the disc’s RPM with your intended application prevents dangerous overspeeding and enhances the efficiency of your work.

Selecting Appropriate Grinder Discs

Selecting the right grinder disc is essential for ensuring both efficiency and safety during your cutting or grinding tasks. Match the disc’s RPM rating with your grinder’s no-load speed to avoid dangerous accidents. Consider these factors when selecting:

- Higher RPM discs for faster cutting speeds

- Lower RPM discs for controlled grinding applications

- Diameter of the disc, as a 4.5-inch disc typically spins faster than a 7-inch under the same load

- Compatibility with your grinder’s specifications to enhance performance

Understanding Disc Compatibility Factors

Disc compatibility plays an essential role in the safe and effective operation of your angle grinder. Selecting accessories rated for your grinder’s no-load speed is vital to prevent failures during use. For example, if your grinder’s no-load speed is 12,000 RPM, verify that any grinding discs you choose can handle that speed, as actual working speeds may drop to around 8,000 RPM due to resistance. Always refer to the manufacturer’s guidelines for minimum and maximum RPM ratings for both your angle grinder and its accessories. This careful selection guarantees that the RPM rating of the disc exceeds the grinder’s no-load speed, promoting safety and peak performance while you work. Don’t compromise on disc compatibility; your safety depends on it.

Matching RPM With Tasks

Verifying that the RPM ratings of your angle grinder and its accessories align with the tasks at hand is essential for peak performance. Consider the following:

- No-load speed of your tool, typically between 6,500 to 12,000 RPM.

- Cutting discs rated for the same or lower RPM to prevent hazards.

- Operational speeds that drop under load affecting cutting efficiency.

- A powerful motor that can handle the demands of tougher materials.

Using a cutting disc rated above your grinder’s no-load speed can lead to inefficient cutting and increased wear. Always match the revolutions per minute of accessories with your grinder’s specifications to guarantee safety and achieve that efficient cutting you seek, liberating your projects from delays and frustrations.

Safety Tips: Understanding No-Load Speed for User Protection

While it might be tempting to focus solely on cutting power, understanding no-load speed is essential for guaranteeing your safety when using an angle grinder. The no-load speed indicates the maximum RPM your grinder can achieve without any load, serving as a critical benchmark for performance.

| Aspect | Details | Safety Implications |

|---|---|---|

| No-Load Speed | Maximum RPM without load | Establishes safe operating limits |

| Disc RPM Rating | Must meet or exceed grinder’s no-load speed | Prevents catastrophic disc failure |

| Material Resistance | Actual speeds lower under load | Highlights need for caution during operation |

| Regular Maintenance | Inspect grinder and components | Guarantees compatibility and operational safety |

| User Protection | Understand RPM ratings for safe use | Reduces injury risks associated with misuse |

Always guarantee your disc is rated appropriately for your grinder’s no-load speed to maintain user protection and avoid accidents.

Real-World Applications of No-Load Speed in Angle Grinders

Understanding no-load speed not only enhances safety but also plays an essential role in real-world applications of angle grinders. The no-load speed, typically ranging from 7,000 to 12,000 RPM, directly influences cutting efficiency and the suitability for various materials. When selecting a grinder, consider the following:

- The RPM drop under material resistance

- The type of work—cutting, grinding, or polishing

- The compatibility of accessories with grinder specifications

- The choice between corded models and cordless models

For instance, a grinder rated at 10,000 RPM may struggle to maintain that speed when cutting tougher materials, often dropping to 8,000 RPM or lower. This impacts the overall cutting speed and finish quality. By understanding no-load speed, you can make informed decisions, ensuring your tool meets the demands of your projects and operates safely and effectively under load.

Frequently Asked Questions

What Is No-Load Speed in an Angle Grinder?

No-load speed in an angle grinder refers to the maximum RPM achievable without resistance. Understanding this helps you assess motor performance, tool efficiency, and safety precautions, considering speed variations and operational guidelines for ideal use.

What Is the Meaning of RPM in Grinder?

RPM in a grinder measures its speed, impacting grinding efficiency and motor power. Guarantee wheel compatibility and adhere to safety standards. Proper tool maintenance enhances user experience, while vibration control minimizes fatigue during operation.

What Is the Best RPM for an Angle Grinder?

For ideal cutting, aim for 8,000 to 12,000 RPM with your angle grinder. Consider wheel selection, power requirements, and grinding techniques, while always prioritizing safety precautions and regular maintenance for best performance.

Should the Grinder’s Max RPM Never Exceed the Rated RPM of the Grinding Wheel?

Yes, your grinder’s max RPM should never exceed the grinding wheel’s rated RPM. Confirming grinding wheel compatibility enhances safety precautions, optimizes motor performance, and guarantees effective tool maintenance under varying load conditions across different grinding wheel types.

Conclusion

In the world of angle grinders, a high no-load speed doesn’t guarantee superior performance under load; it’s a delicate balance. While RPM ratings signal potential, real-world scenarios expose the grinder’s limitations against material resistance. Choosing the right accessories can either enhance efficiency or lead to frustration. By understanding these dynamics, you equip yourself for safer, more effective use. Ultimately, knowing when to push your grinder and when to hold back can mean the difference between a job well done and costly mistakes.