When using an angle grinder, torque and speed are essential for performance. Torque helps maintain disc speed under load, especially for cutting tasks, while higher RPM enhances material removal efficiency in grinding. For cutting, aim for at least 6 Amps of torque alongside high RPM (10,000-12,000). In contrast, grinding requires lower RPM (7,000-8,500) with adequate torque to prevent stalling. Understanding how to balance these factors can greatly improve your grinding and cutting efficiency, leading to ideal results.

Understanding Torque and Speed in Angle Grinders

When it comes to angle grinders, understanding the interplay between torque and speed is crucial for ideal performance. Torque, measured in Amps, is important for maintaining disc speed under load. Higher torque prevents your angle grinder from bogging down during heavy cutting or grinding tasks. Speed, indicated by RPM (revolutions per minute), considerably impacts cutting efficiency. For aggressive cutting, a higher RPM of 10,000-12,000 is preferable, while lower RPMs of 7,000-8,500 offer controlled torque for grinding tasks. Balancing torque and speed is essential; high RPMs enable faster cutting, but without sufficient torque, you risk stalling when working with tougher materials. For general DIY projects, aim for a minimum of 6 Amps and 10,000 RPM to guarantee effective performance. By grasping the relationship between torque and speed, you can select the right angle grinder tailored to your project needs, maximizing efficiency and safety.

Why Does Torque Matter for Cutting Tasks?

Torque plays a critical role in cutting tasks because it directly affects your grinder’s ability to maintain speed under load. When faced with tough materials, higher torque guarantees effective cutting without stalling, allowing for deeper penetration and more efficient material removal. Selecting a grinder with the right torque is essential for achieving peak performance, especially in heavy-duty applications.

Torque Determines Cutting Power

Cutting efficiency hinges on the interplay of torque and speed, making torque an vital factor in any cutting task. High torque enables your angle grinder to maintain speed under load, preventing it from bogging down during heavy cuts. When you’re tackling tough materials like metal or concrete, a grinder with a torque rating of 6 Amps or more can considerably enhance your cutting power. This ability to sustain higher RPM is essential for aggressive cutting and keeping momentum. The balance between torque and speed guarantees that the disc doesn’t stall, allowing for efficient material removal. For peak performance, choose an angle grinder that offers both high torque and appropriate RPM ratings to achieve precise, effective results.

Essential For Material Removal

Maintaining consistent torque is key for effective material removal during cutting tasks. Torque directly impacts your angle grinder’s ability to sustain speed and power under load, especially when cutting through tougher materials like steel or concrete. Higher torque ratings enhance performance, allowing you to cut without bogging down, particularly at lower RPMs where precision is critical. The interplay between torque and RPM is essential; adequate torque guarantees the grinder maintains necessary cutting force without losing momentum. For demanding applications, aim for a grinder with at least 6.0 Amps of torque to guarantee efficiency. By optimizing torque, you’ll achieve a faster material removal rate, guaranteeing consistent engagement with the material and enhancing your overall cutting experience.

Why Is Speed Important for Grinding Applications?

In grinding applications, speed is vital because it directly influences edge speed and material removal efficiency. Operating within the ideal RPM range of 7,000 to 12,000 guarantees your grinder can perform effectively without stalling under load. Choosing a grinder that exceeds the RPM rating of your disc is essential for achieving the desired results and maintaining safety.

Edge Speed Considerations

While speed plays a vital role in grinding applications, understanding its impact on edge speed is essential for achieving ideal results. Edge speed, measured in inches per minute (ipm), directly affects grinding efficiency. For example, a 4.5-inch disc at 11,000 RPM achieves about 155,540 ipm, outperforming a 7-inch disc at 6,500 RPM, which reaches around 143,000 ipm. Larger disc circumference enhances material removal by providing a greater contact patch. Maintaining ideal RPM is vital; higher RPMs yield faster cuts for aggressive tasks, while lower RPMs offer control for precision grinding. Remember, the relationship between speed and torque matters; sufficient torque prevents blade bogging under load, ensuring effective grinding without compromising safety.

Material Removal Efficiency

Speed is a critical factor in grinding applications because it directly influences material removal efficiency. Higher RPM allows for faster material removal, especially when cutting through hard surfaces. For ideal results, aim for a speed range of 10,000 to 12,000 RPM; this prevents the tool from bogging down under load while enabling aggressive cutting. The edge speed considerably enhances efficiency—consider a 4.5-inch disc spinning at 11,000 RPM, achieving an impressive 155,540 inches per minute. In contrast, lower RPM tools around 6,500 RPM yield slower material removal rates, making them less effective for grinding. The size of the grinding disc also matters; a larger circumference increases the contact patch, further elevating material removal when paired with sufficient motor power.

Optimal RPM Selection

Choosing the ideal RPM for your grinding applications is essential to achieving the desired results and prolonging tool life. The best RPM for grinding tasks usually falls between 7,000 and 8,500 RPM, ensuring controlled torque and preventing overheating. Here’s why RPM matters:

- Higher RPM speeds boost material removal rates in cutting applications.

- Lower RPM settings enhance abrasive disc contact with the surface.

- Controlled torque at lower RPMs minimizes disc wear.

- Selecting the right RPM maintains a smoother finish.

- Managing RPM effectively can greatly extend disc lifespan.

Understanding the relationship between RPM and torque helps you select the best settings for grinding, ensuring efficiency without compromising tool integrity.

How to Balance Torque and Speed for Enhanced Grinder Performance

Balancing torque and speed is vital for maximizing the performance of your angle grinder, especially when tackling diverse materials and tasks. To achieve ideal performance, you need to understand the interplay between torque and RPM. Higher torque is essential for maintaining consistent disc speed under load, particularly when cutting through tougher materials. Grinders with higher amperage (above 6.0 Amps) excel in this regard. For aggressive cutting, aim for higher RPM, typically in the range of 10,000-12,000. Conversely, when grinding, lower RPM (7,000-8,500) provides better control and precision. A balanced combination, such as a grinder with 6.7 Amps and 11,800 RPM, guarantees effective material removal without stalling. Always verify that the grinder’s RPM exceeds the disc’s rated RPM to enhance safety and prevent failures during operation. By mastering this balance, you can greatly improve your grinder performance for any application.

How to Choose the Right Grinder for Your Needs

Understanding the balance of torque and speed helps when selecting the right angle grinder for your specific needs. To make an informed choice, consider the following aspects:

Choosing the right angle grinder requires understanding torque and speed to meet your specific needs.

- Size: Small grinders (4-5 inches) are great for precise work, while larger models (7 inches and above) tackle heavy-duty tasks.

- Power Source: Corded grinders offer constant power; cordless models provide portability, typically ranging from 18V to 60V.

- Amperage Rating: Aim for a minimum of 6.0 Amps for serious use; higher ratings maintain disc speed during heavy tasks.

- RPM Rating: Higher RPM (10,000-12,000) suits aggressive cutting; lower RPM (7,000-8,500) is better for controlled torque.

- Disc Compatibility: Verify the grinder’s RPM rating exceeds the disc’s to prevent failures and enhance performance for your cutting or grinding tasks.

Common Misconceptions About Torque and Speed

While many users assume that higher RPM always leads to superior performance, this belief can be misleading. Understanding the relationship between torque and speed is important for enhancing your angle grinder for cutting or grinding tasks.

| Application | Speed (RPM) | Torque | Power Rating (Amps/Watts) | Disc Type |

|---|---|---|---|---|

| Cutting | High | Low | Higher Power | Thinner Discs |

| Grinding | Moderate | High | Moderate to Higher Power | Thicker Discs |

| Material Removal | Fast | Varies | Higher Power | Depends on Task |

For grinding, adequate torque is necessary to maintain consistent pressure, preventing bogging down. Conversely, cutting tasks benefit from higher RPM for rapid material removal. It’s essential to match the disc type and size to your application to achieve the best performance and avoid overheating or inefficient results.

Real-World Examples of Torque and Speed in Angle Grinders

Many users find that torque and speed play distinct roles in real-world applications of angle grinders. Understanding how these factors affect performance can greatly enhance your results during cutting and grinding tasks. Here are some key examples:

- High-speed grinders (11,000 RPM) are ideal for rapid cutting of thin materials.

- High-torque grinders maintain consistent speed under load, ensuring effective cutting of dense materials.

- Low RPM models (around 6,500) excel in grinding, providing better control for material removal.

- Heavy-duty applications require grinders with both high torque and RPM to prevent stalling on thick materials.

- Task-specific selection is essential; cutting favors speed, while grinding benefits from increased torque.

Safety Considerations When Using High Torque or Speed Grinders

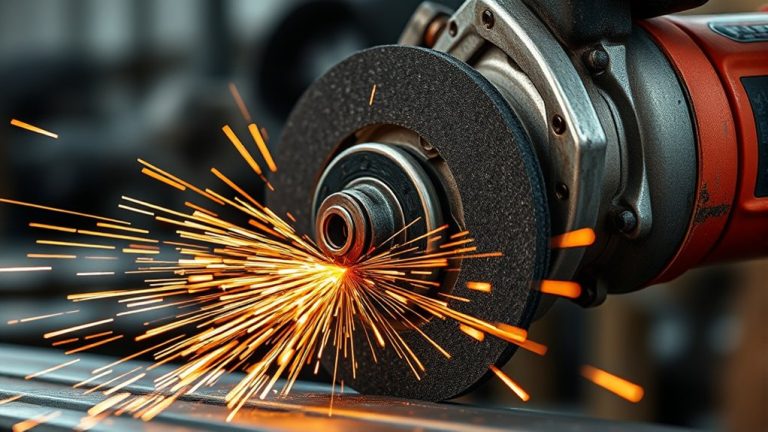

Using high torque or speed grinders can greatly enhance your efficiency in various tasks, but it’s crucial to prioritize safety. Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and face shields, to shield yourself from flying debris and sparks. High-speed grinders generate significant heat; allow them to cool down during extended use to prevent overheating, which can lead to burns or tool failure.

Before starting, check the RPM rating of your grinding disc to verify compatibility with your grinder’s speed. Using a disc rated for lower RPM risks dangerous breakage and severe injuries. Maintain a firm grip and a balanced stance while operating these powerful tools to minimize the risk of losing control. Regularly inspect and replace any worn or damaged grinding discs, as compromised discs can shatter at high speeds, posing serious safety hazards. Prioritizing these precautions will help guarantee a safer working environment.

Maintenance Tips for Long-Lasting Grinder Performance

To guarantee your angle grinder performs at its best and lasts longer, regular maintenance is essential. Neglecting proper care can lead to wear and tear, safety hazards, and diminished efficiency. Here are some key tips for effective grinder maintenance:

Regular maintenance is crucial for optimal angle grinder performance and longevity, helping to prevent wear, safety risks, and efficiency loss.

- Clean dust and debris from the grinder after each use, focusing on motor vents to prevent overheating.

- Inspect and replace worn or damaged discs immediately to maintain peak performance.

- Lubricate moving parts as per the user manual to avoid unnecessary wear and tear.

- Store grinders and accessories in a dry place, protecting them from rust and damage.

- Check electrical components and cords regularly for signs of wear, replacing them promptly to prevent electrical failures.

Frequently Asked Questions

Is Variable Speed Important for Angle Grinders?

Yes, variable speed’s essential for angle grinders. It enhances user control, ensuring torque output matches material compatibility. This promotes performance efficiency, tool longevity, and safety features, maximizing versatility benefits for various applications.

Is More Rpm Better for an Angle Grinder?

More RPM isn’t always better; consider torque importance, speed settings, and material compatibility. Balancing performance with safety guarantees tool longevity and meets user preferences for various application types, enhancing overall efficiency and effectiveness.

What Speed Angle Grinder for Cutting Metal?

For cutting metal, your angle grinder should run at 10,000 RPM or higher. Prioritize speed ratings, use appropriate blade types, and remember safety measures to tackle various material thicknesses and enhance performance through proper tool maintenance.

What Is the Difference Between Grinding and Cutting on an Angle Grinder?

Grinding techniques focus on surface refinement using thicker discs at lower RPMs, while cutting methods employ thinner discs for rapid slicing at higher RPMs. Proper disc selection guarantees material compatibility, enhances efficiency, and maintains safety precautions.

Conclusion

In the world of angle grinders, finding the right balance between torque and speed is like mastering a dance; each movement complements the other for optimal performance. Whether you’re cutting through tough materials or grinding for a smooth finish, understanding these dynamics guarantees efficiency and precision. By considering your specific tasks and choosing the right grinder, you’ll navigate your projects with confidence, transforming raw materials into polished results. Prioritize safety and maintenance, and your tools will serve you well for years to come.