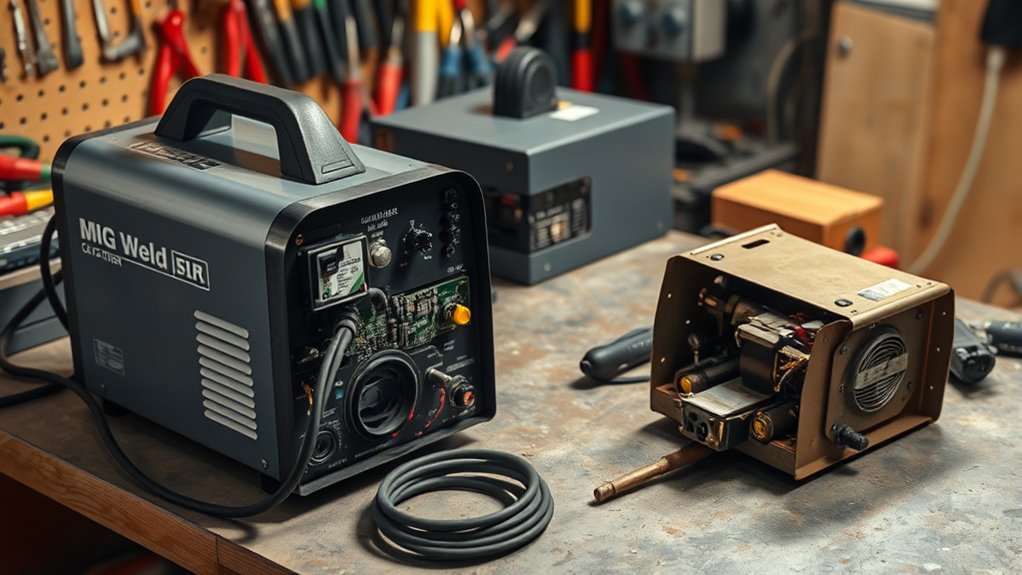

You might think converting a MIG welder to a plasma cutter is practical, but it’s technically complex and not advisable. The substantial differences in voltage and current requirements mean you’d face major modifications and potential safety hazards. MIG welders operate at lower voltages, whereas plasma cutters need around 10kV to start the arc. This transformation isn’t straightforward, but understanding the intricacies could save you time and resources in your metalworking endeavors.

Understanding the Basics of MIG Welders and Plasma Cutters

When delving into the mechanics of MIG welders and plasma cutters, it’s crucial to grasp their fundamental differences and applications.

Understanding MIG fundamentals involves recognizing that these welders utilize a continuously fed wire electrode and an inert gas to create a welding arc. This method is primarily for joining materials, operating at lower voltage and current levels than plasma cutters.

In contrast, plasma characteristics are defined by the use of ionized gas to cut through metals. Plasma cutters operate with high-voltage direct current, requiring around 10kV to initiate an arc. The process involves blowing compressed air through a narrow nozzle to form a high-temperature arc, exceeding 20,000°F, for precise metal cutting.

Due to their distinct internal components and operational mechanisms, attempting to convert a MIG welder to a plasma cutter is challenging and often doesn’t meet the performance or safety standards of dedicated plasma cutting equipment.

Key Differences Between Welding and Cutting Technologies

Although both MIG welding and plasma cutting serve essential roles in metalworking, their technologies diverge considerably in relation to operation and purpose.

MIG welding employs a continuous wire feed to join metals through fusion, making it ideal for welding applications. In contrast, plasma cutting utilizes ionized gas to efficiently melt and sever materials, showcasing superior cutting techniques. This distinction is rooted in their power requirements and operational mechanisms.

MIG welding fuses metals with wire feed, while plasma cutting uses ionized gas for precise severing.

Plasma cutters demand high-voltage direct current and compressed air to maintain a cutting arc, with higher amperages necessary for effective cutting processes.

MIG welders, however, operate at lower voltages suited for fusion. Additionally, plasma cutting creates cleaner edges with minimal thermal distortion, thanks to its narrower cut, unlike MIG welding, which generates a heat-affected zone that can alter base metal properties.

Consequently, plasma cutting excels in fabrication and demolition, while MIG welding remains pivotal for metal joining.

Technical Challenges in Converting Welders to Plasma Cutters

When you’re converting a MIG welder to a plasma cutter, one of the main challenges is modifying the voltage requirements to meet the plasma cutter’s needs, which include an initial spark at around 10kV.

You must also integrate robust safety measures, like circuit protection, to mitigate potential electrical hazards during operation.

Additionally, incorporating a compressor system is essential to replace the pressurized air function inherent in plasma cutters, which is absent in MIG welders.

Voltage Requirements Explained

Converting a MIG welder to a plasma cutter presents significant voltage challenges due to the fundamental differences in their power requirements.

Plasma cutters demand high-voltage direct current (DC) for effective operation, with voltage specifications around 10kV for arc initiation. In contrast, MIG welders operate at much lower voltages, typically insufficient for plasma cutting without extensive modifications.

The operational voltage for plasma cutters generally ranges from 125V to 140V, while MIG welders fall short of these requirements. Additionally, maintaining current stability is essential, as plasma cutting necessitates a stable current of approximately 50 Amps or more.

MIG welders often aren’t designed for such high current delivery, further complicating the conversion process. Therefore, these voltage discrepancies highlight the technical hurdles in adapting a MIG welder for plasma cutting.

Safety Considerations Highlighted

Despite the allure of transforming a MIG welder into a plasma cutter, it’s vital to acknowledge the inherent safety risks tied to this conversion. The high-voltage requirements, around 10kV for the initial spark, exceed typical MIG welder capabilities and pose a significant risk of electric shock if not properly insulated.

Ensuring adequate grounding is imperative. The use of ionized compressed air instead of inert gas introduces further complications. Hence, integrating proper safety equipment and protective gear is non-negotiable. This includes UV protection to prevent burns and appropriate circuit protection to avoid equipment failure.

Without these precautions, you risk creating hazardous conditions, such as fire risks and damage. Thorough understanding and careful execution are fundamental to mitigate these dangers effectively.

Safety Considerations and Risks Involved in Conversions

Understanding the safety considerations and risks involved in converting a MIG welder to a plasma cutter is essential, given the technical complexities and potential hazards. You must prioritize safety protocols to mitigate electrical hazards, as plasma cutting arcs require approximately 10 kV for initiation. This high voltage poses significant danger if not properly managed.

Prioritize safety: plasma cutting arcs need 10 kV, posing significant electrical hazards if not properly managed.

Make sure that your setup includes adequate circuit protection to prevent malfunctions that could lead to fires or equipment damage.

In addition, protect against UV radiation. Plasma cutting emits intense UV light that can cause severe skin burns and eye damage. Use appropriate shade lenses, specifically shade 8, to safeguard your vision.

Moreover, a clean and dry air supply is critical to avoid torch damage, adding another layer of complexity to the conversion process.

Without thorough research and understanding of these operational differences, your attempt at conversion could result in an unsafe setup with potentially dangerous outcomes.

Cost-Benefit Analysis of Conversion Versus Purchasing

While evaluating the decision between converting a MIG welder to a plasma cutter or purchasing a dedicated plasma cutter, it’s essential to analyze the financial and technical implications.

Converting might appear cost-effective initially, but the conversion costs can be substantial due to requirements for a high-voltage rectifier and air supply systems.

Consider these aspects:

- Performance and Efficiency: Dedicated plasma cutters generally outperform converted units, offering stable operation with higher power capacity.

- Safety and Reliability: DIY conversions can introduce fire hazards and improper setups, compromising safety and reliability.

- Long Term Value: Dedicated plasma cutters provide consistent performance and are designed specifically for plasma cutting, reducing ongoing maintenance issues that can arise from a converted setup.

Investing in a dedicated plasma cutter typically yields better long-term value, especially given the complexity of plasma cutting technology and the potential for ongoing technical challenges with converted equipment.

User Experiences and Insights From DIY Projects

When you’re tackling the conversion of a MIG welder into a plasma cutter, anticipate challenges like achieving the necessary voltage and current levels, often requiring components such as a 200 A bridge rectifier.

It’s vital to prioritize safety measures, especially to protect against UV radiation, by utilizing proper gear.

While a converted unit might offer cost savings, be aware of potential limitations in efficiency and reliability compared to a dedicated plasma cutter, with sufficient air supply being essential for peak performance.

DIY Conversion Challenges

Tackling the challenge of converting a MIG welder to a plasma cutter requires a detailed understanding of the technical hurdles involved. Your journey begins with mastering conversion techniques and meticulous component selection.

The standard MIG welder isn’t designed for the high-voltage direct current needed for plasma cutting, necessitating specialized components like a bridge rectifier and flyback transformer.

Successful DIY projects depend heavily on:

- Effective air supply: A pressurized air system is vital for propelling the ionized gas.

- Circuit protection: Essential for preventing accidents and equipment damage.

- Component compatibility: Ensuring selected parts can handle the required voltage.

Users have reported mixed experiences; improper setups can lead to inefficiencies and potential safety concerns.

Approach each step with a critical, analytical mindset to enhance success.

Safety Measures Importance

Converting a MIG welder into a plasma cutter presents not just technical challenges but also significant safety considerations.

When you engage in this conversion, ensuring the use of proper safety gear is paramount. UV radiation from welding arcs can lead to severe skin burns, exposing you to health risks if not adequately protected. Many DIY enthusiasts underestimate these dangers, often resulting in painful sunburns.

Always wear long sleeves and UV-blocking eyewear. Integrating sunscreen can further shield your skin from harmful radiation. The longer you work, the higher the risk, making protective clothing and proper shielding non-negotiable.

Additionally, incorporating circuit protection and safety features in your setup minimizes hazards associated with high-voltage operations, ensuring a safer working environment.

Efficiency and Limitations

While the idea of converting a MIG welder into a plasma cutter might seem appealing, the process often reveals significant efficiency and performance limitations. Users frequently encounter efficiency concerns due to the distinct operational mechanisms and high-voltage requirements for plasma cutting.

MIG welders aren’t inherently capable of achieving the approximate 10kV needed for the initial plasma spark, posing a substantial hurdle.

- Voltage Deficiency: MIG welders struggle to provide the high-voltage direct current essential for plasma cutting without extensive modifications.

- Air Supply Challenges: Adequate air flow, critical for effective plasma cutting, often necessitates additional components like a compressor.

- Reliability Risks: The compromised reliability and performance limitations typically lead experienced users to favor investing in dedicated plasma cutters instead.

Ultimately, the risks may outweigh the potential cost savings.

Recommendations for Optimal Metal Cutting Solutions

When seeking ideal metal cutting solutions, understanding the nuances of plasma cutting technology is essential. Plasma cutter types and cutting techniques vary, but dedicated plasma machines surpass multi-process units in reliability and efficiency. They stabilize cutting currents at 50 Amps or more, ensuring effective operations.

The intricate process begins with a 10kV arc initiation, shifting to a stable cutting arc, which underscores the importance of equipment designed explicitly for plasma cutting.

Opt for quality machines that incorporate pre-flow gases to prevent torch damage. Unlike modified welders, these machines are engineered for plasma applications. Although they might seem pricier due to complex design and components, they offer long-term savings by reducing operational costs and delivering consistent performance.

Invest in dedicated plasma cutters to achieve precision and reliability in your metal cutting tasks, ensuring your equipment meets the high-voltage DC requirements for peak functionality.

Frequently Asked Questions

Can a Converted Plasma Cutter Damage the Original MIG Welder?

Yes, a converted plasma cutter can potentially damage the original MIG welder. You should follow safety precautions and understand conversion risks thoroughly. Analyze voltage differences and component compatibility to prevent unexpected failures and maintain equipment integrity.

What Materials Can a Converted Plasma Cutter Handle?

Imagine slicing through metal like butter. You can handle various material types, including steel and aluminum, with cutting thickness dependent on power settings. Analyze your plasma cutter’s specs to guarantee peak performance and precise cuts.

How Does Conversion Affect the Lifespan of a MIG Welder?

Conversion implications on the lifespan of a MIG welder can be significant. You’ll find equipment durability might decrease due to altered electrical demands and thermal stress, potentially leading to premature wear if components aren’t designed for dual-functionality.

Are There Specific Brands Better Suited for Conversion?

When considering brand compatibility for conversion, some brands, like Lincoln and Miller, are more adaptable. Don’t jump the gun; analyze each brand’s technical specs to guarantee a smooth conversion process without compromising performance or efficiency.

Can Conversion Void the Warranty on a MIG Welder?

Yes, converting a MIG welder can void the warranty. Always check warranty policies and manufacturer guidelines. They often specify modifications, like plasma cutter conversion, that can invalidate coverage due to unapproved alterations or potential equipment damage.

Conclusion

Converting a MIG welder to a plasma cutter is like trying to turn a bicycle into a motorcycle; technically possible, but fraught with challenges and risks. You’d face significant technical hurdles, from voltage mismatches to safety hazards, making it a complex and unsafe DIY project. Instead, invest in a dedicated plasma cutter. It’s a smart, cost-effective choice that guarantees reliability and peak performance for your metal cutting needs, steering clear of potential pitfalls and inefficiencies.