You’re probably wondering if a plasma cutter can weld. It’s important to know that a plasma cutter is designed for precision cutting, not welding. It uses a high-velocity jet of ionized gas to slice through metal, creating clean cuts but leaving surfaces that might be unsuitable for welding without proper preparation. Understanding the limitations and potential of plasma cutting is vital. Curious about how this affects your welding projects? Let’s explore further.

Understanding Plasma Cutting

Plasma cutting, a powerful tool in metal fabrication, employs a high-velocity jet of ionized gas to efficiently melt and sever metal. This method is integral to plasma technology, offering precision and speed across various materials.

By harnessing advanced cutting techniques, you can achieve clean cuts that are essential for intricate designs and heavy-duty applications. Devices like the Yes Welder CT 2050 enhance this process with built-in air compressors, ensuring portability and convenience.

Achieve clean, intricate cuts with devices like Yes Welder CT 2050, offering portability and convenience through built-in air compressors.

However, the process can leave dross and oxidation on edges, necessitating thorough cleaning for ideal results in subsequent tasks. Dual voltage capability further amplifies a cutter’s versatility, allowing operation on both 110V and 220V, adapting to diverse environments.

While plasma cutting excels in material separation, it’s vital to understand its limitations, particularly in preparing surfaces for welding, where meticulous attention to detail is required to maintain structural integrity and aesthetic quality.

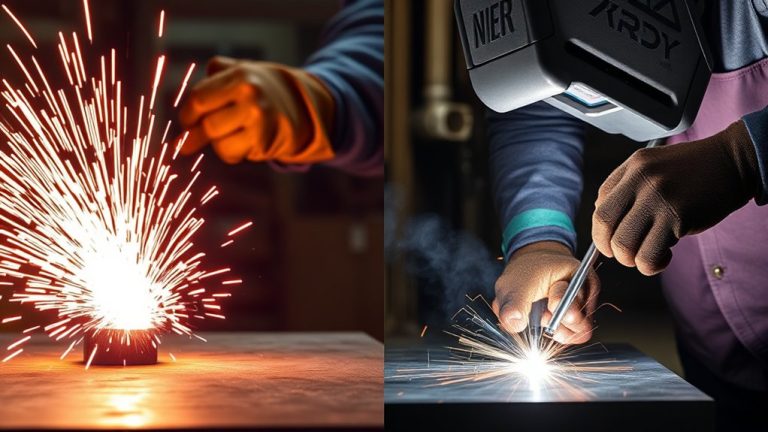

Challenges of Welding Over Plasma Cuts

While plasma cutting offers precision and speed, translating these advantages into welding can present challenges. Plasma contamination from dross and oxidation is a primary concern, as it can compromise weld quality.

Both stick and TIG welding techniques struggle with unprepared plasma cut surfaces, often resulting in weak and unattractive joints. The impurities left by plasma cutting lead to inconsistent bead sizes and poor aesthetics, making it difficult to achieve professional results.

To address these issues, you must understand the impact of plasma contamination on your welding techniques. Without proper preparation, you risk producing welds that lack strength and visual appeal.

Cleaning the cut edges by removing dross and oxidation is essential. This preparation step greatly enhances the weld quality and appearance, leading to smoother and more controlled welds.

Investing time in surface preparation guarantees that your welding efforts align with the precision and speed you’ve achieved with plasma cutting.

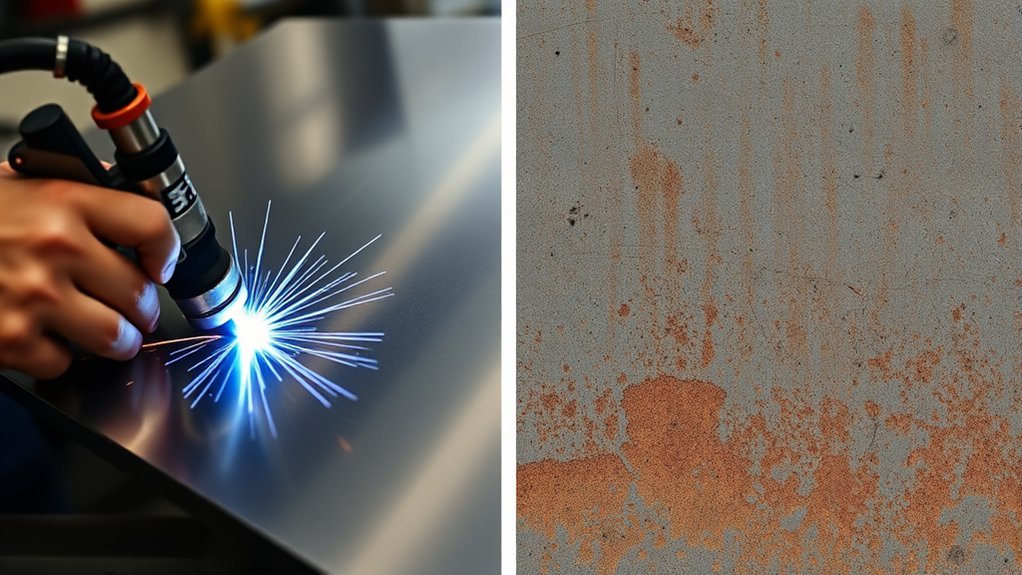

Surface Preparation for Welding Success

To achieve effective welding, you must focus on thorough surface preparation, as plasma-cut metal often harbors dross and oxidation that can compromise weld integrity.

Removing these contaminants with tools like grinding wheels or flap discs is essential for ensuring clean surfaces, which leads to consistent bead quality and robust joints.

Importance of Clean Surfaces

Understanding the importance of clean surfaces is fundamental to achieving welding success. Surface contaminants, such as dross and oxidation, can severely compromise weld quality, leading to weak joints.

By cleaning the metal before welding, you greatly enhance the weld’s quality, ensuring smoother puddles and better arc control. Utilizing tools like grinding wheels or flap discs to remove impurities from plasma-cut edges is essential. This preparation results in consistent and aesthetically pleasing welds.

Welds on clean metal exhibit improved characteristics, such as flatter beads in stick welding and easier filler addition in TIG welding. Ultimately, ensuring surfaces are clean before welding directly impacts the strength, appearance, and reliability of the final joint, making this step indispensable in the welding process.

Removing Dross Effectively

Since effective welding starts with proper preparation, removing dross from plasma-cut edges is essential for success. This residue can compromise welding quality by introducing contamination and hindering penetration.

To guarantee ideal results, consider these key points in dross removal:

- Utilize grinding wheels and flap discs to effectively clean plasma-cut edges.

- Eliminate oxidation to prepare metal surfaces for welding.

- Achieve smoother welding puddles and enhanced arc control with a clean surface.

- Aim for consistent bead size, improving overall weld integrity.

- Shift from challenging welding tasks to more manageable ones with thorough surface preparation.

Tools for Metal Cleaning

A clean metal surface serves as the foundation for successful welding, and achieving this requires the right tools for metal cleaning. Effective surface treatment is essential to remove contaminants like dross and oxidation that can compromise weld quality.

Utilize grinding wheels and flap discs to efficiently remove impurities from plasma cut edges, ensuring a pristine surface for welding. These tools enhance metal cleaning by leading to smoother weld puddles and better arc control, which are critical for strong and aesthetically pleasing welds.

Welding on dirty surfaces often results in weak joints and inconsistent bead appearances, underscoring the importance of thorough cleaning. Prioritizing surface preparation not only strengthens the weld but also enhances its appearance, making it a fundamental step in metalworking.

Comparing Welds: Clean vs. Dirty

Although it might be tempting to weld directly over a plasma-cut surface, doing so often leads to undesirable results. The presence of dross and oxidation from plasma cutting can create dirty welds, characterized by irregularities, brittleness, and poor aesthetics.

In contrast, clean welds on well-prepared surfaces exhibit superior strength and appearance. Here’s what you need to take into account:

- Contaminants: Plasma cuts often leave dross, leading to weld contamination.

- Bead Consistency: Clean welds show consistent bead size, while dirty welds are uneven.

- Arc Control: TIG welding on clean surfaces enhances control, improving quality.

- Filler Addition: Clean metal facilitates better filler metal integration.

- Structural Integrity: Proper preparation reduces porosity, enhancing weld strength.

Using a stick welding process on clean metal guarantees flatter, manageable beads, unlike those on contaminated surfaces.

Always prioritize cleaning to achieve ideal weld quality and minimize structural defects.

Tools for Effective Surface Cleaning

To guarantee ideal weld quality on plasma cut surfaces, select appropriate cleaning tools such as grinding wheels and flap discs.

Grinding wheels provide aggressive material removal, effectively eliminating dross and oxidation, while flap discs offer a finer finish with controlled abrasion.

Choose tools based on your specific cleaning needs to achieve clean metal surfaces, which are essential for strong, consistent welds.

Grinding Wheels Benefits

When preparing metal surfaces for welding, grinding wheels offer an efficient solution for removing dross and oxidation left from plasma cutting.

Selecting the right grinding wheel types and grit selection is essential for achieving peak surface preparation. These tools not only enhance weld quality but also promote better arc control by minimizing contamination.

Here are some benefits of using grinding wheels:

- Variety of grits and types: Tailor your surface preparation based on the material and the desired finish.

- Improved weld quality: Achieve cleaner welds with reduced contaminants.

- Enhanced arc control: Guarantee a stable welding process.

- Consistent performance: Regular maintenance and replacement maximize efficiency.

- Time efficiency: When combined with other tools, they reduce preparation time before welding.

Use grinding wheels for effective, clean metal surfaces.

Flap Discs Advantages

Flap discs offer unparalleled versatility for surface cleaning, seamlessly merging grinding and sanding capabilities into one tool. They’re your go-to for cleaning plasma-cut surfaces before welding.

The flap disc benefits from overlapping layers of abrasive materials, ensuring consistent surface finishes while minimizing heat that could warp metal. You can choose from various grits to match the abrasiveness required, whether for heavy material removal or fine finishing.

Their unique design allows them to conform to surface contours, providing better contact on irregular shapes than traditional grinding wheels. Using flap discs enhances weld quality by creating clean, smooth surfaces free from dross and oxidation, ensuring stronger and more visually appealing joints.

They’re an essential tool for achieving superior welding outcomes.

Cleaning Tools Selection

Selecting the right cleaning tools is vital for preparing metal surfaces effectively before welding. Proper cleaning techniques are essential to remove dross and oxidation, guaranteeing peak weld quality.

To achieve this, consider using:

- Grinding wheels: Ideal for removing thicker dross, enhancing surface maintenance.

- Flap discs: Provide a smoother finish, improving weld preparation.

- Wire brushes: Effective for cleaning smaller impurities, guaranteeing a pristine surface.

- Quality tools: Invest in durable tools to minimize contamination risk during welding.

- Consistent cleaning: Regular maintenance leads to better arc control and stronger welds.

Using these tools guarantees a clean surface, enhancing arc control and producing smoother puddles.

Recommendations for Optimal Welding Practices

Before you attempt welding on plasma-cut surfaces, it’s crucial to guarantee they’re thoroughly cleaned to enhance both quality and strength.

Employ proper welding techniques by utilizing grinding wheels or flap discs to remove any dross or oxidation. This preparation guarantees a smoother surface, improving arc control and bead formation.

When considering metal compatibility, remember that stick welding on clean metal results in flatter, more manageable beads. Avoid welding on dirty surfaces, as they often lead to inconsistent welds.

For TIG welding, starting with clean surfaces facilitates easier filler addition and enhances penetration, effectively reducing contamination risks.

Prioritize the surface condition to maximize your weld’s integrity and appearance. While plasma cutting is efficient, the edges may need additional preparation to meet ideal welding requirements.

If immediate welding is required, you might explore alternative techniques that naturally produce cleaner edges, guaranteeing better outcomes without extensive surface preparation.

Exploring Alternative Cutting Methods

When considering alternative cutting methods, each technique offers distinct advantages regarding surface finish and preparation time for welding. You’ll find that these methods can enhance cutting efficiency and improve surface quality, making them attractive options for your projects.

- Oxy-fuel cutting: Produces cleaner edges suitable for immediate welding, minimizing extensive surface preparation.

- Laser cutting: Offers high precision with minimal heat-affected zones, reducing distortion and enhancing weld quality over plasma cutting.

- Water jet cutting: Utilizes high-pressure water to achieve smooth surfaces, requiring little to no cleaning before welding.

- Band saws: Provide metal cuts with minimal burrs, enabling direct welding without additional surface treatment.

- Shear machines: Efficiently cut metal with clean edges, supporting immediate welding processes.

Each method’s unique properties focus on optimizing the balance between cutting efficiency and the resultant surface quality, thereby streamlining the welding workflow.

Selecting the appropriate technique can greatly impact the overall effectiveness of your welding operations.

Frequently Asked Questions

Can a Plasma Cutter Be Used for Non-Metal Materials?

You can’t use plasma cutting for non-metal applications effectively. Plasma cutters require conductive materials, primarily metals. They work by creating an electrical arc, which doesn’t interact with non-metals, making them unsuitable for such tasks.

What Safety Gear Is Required When Using a Plasma Cutter?

When using a plasma cutter, always wear safety goggles to protect your eyes from sparks and intense light. Keep a fire extinguisher nearby to quickly address any potential fires. Wear flame-resistant clothing, gloves, and appropriate footwear.

How Does Plasma Cutting Affect Metal Thickness?

Plasma cutting allows you to efficiently slice through varying metal thicknesses, considerably impacting metal properties. You’ll find that precise adjustments to the cutter settings enhance cutting efficiency, accommodating both thin and thick metals seamlessly.

Is a Special Power Source Needed for a Plasma Cutter?

Yes, you’ll need a special power source for a plasma cutter. Plasma technology requires a consistent, high-voltage power supply to ionize gas and create a plasma arc capable of cutting through metal efficiently and precisely.

Can Plasma Cutters Be Used Underwater?

Yes, you can use plasma cutters underwater, but they’re limited compared to underwater welding tools. Plasma cutters struggle with water’s conductive interference, reducing efficiency and precision. They’re not ideal for underwater welding tasks requiring high-quality, reliable joints.

Conclusion

In summary, understanding plasma cutting’s capabilities and limitations is essential. Plasma cutters excel at cutting, not welding; they create precise cuts but leave surfaces requiring cleaning. To weld successfully, clean the cut surfaces thoroughly. Compare welds on clean versus dirty surfaces to see the difference. Use effective tools for surface preparation. For best welding, follow recommended practices. Consider alternative cutting methods if necessary. A plasma cutter cuts cleanly; it doesn’t weld seamlessly without preparation.