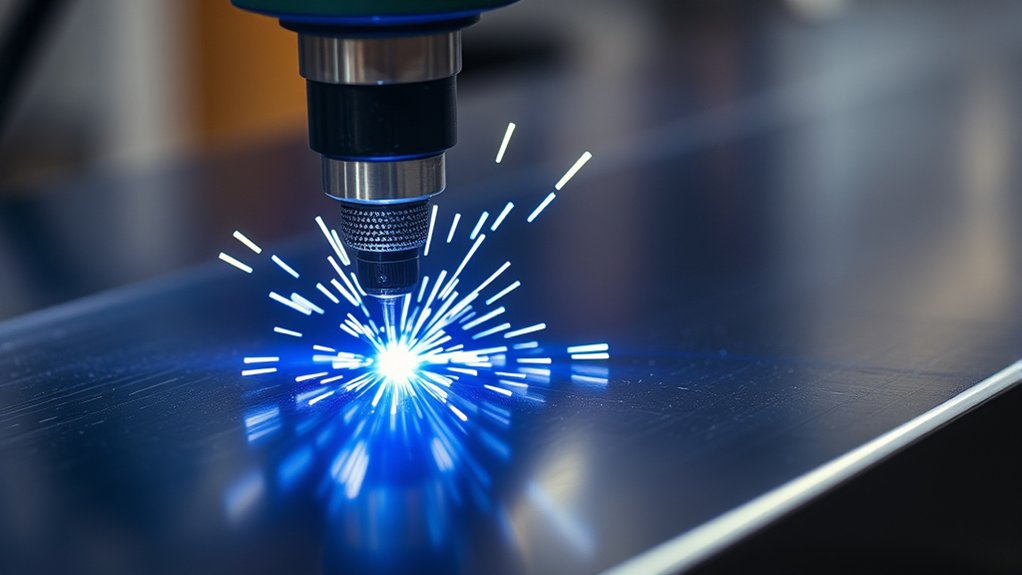

If you’re wondering whether stainless steel can be effectively cut with a plasma cutter, the answer is yes, provided you use clean-cut settings. Selecting the right gas, such as nitrogen or H2Mix, is vital depending on the material’s thickness. Consistent torch speed and angle are key to minimizing dross and achieving sharp edges. Employing CNC controls and automatic torch height adjustment further enhances precision. Want to perfect your cutting technique?

Understanding Plasma Cutting for Stainless Steel

When you explore the intricacies of plasma cutting for stainless steel, it’s vital to contemplate the variables that affect the process’s success. The plasma arc’s interaction with stainless properties is critical, especially in determining the effectiveness of the cut.

Understanding the plasma arc’s interaction with stainless steel properties is crucial for effective cutting.

For stainless steel thicknesses under 5 mm, utilizing nitrogen as the plasma gas enhances precision, given its compatibility with the material’s properties. Conversely, thicker materials benefit from H2Mix or F5 gases due to their capacity to manage the challenging thermal dynamics.

To harness the full potential of your plasma cutter, adjusting torch speed and amperage is necessary. For instance, a setting of 45 inches per minute (ipm), 70 psi, and 30 amps is ideal for .05 stainless steel.

Dross accumulation is a persistent issue, threatening cut quality, yet maintaining a constant torch speed and employing surface conditioning discs can mitigate this. Mastering these factors empowers you to achieve precise cuts.

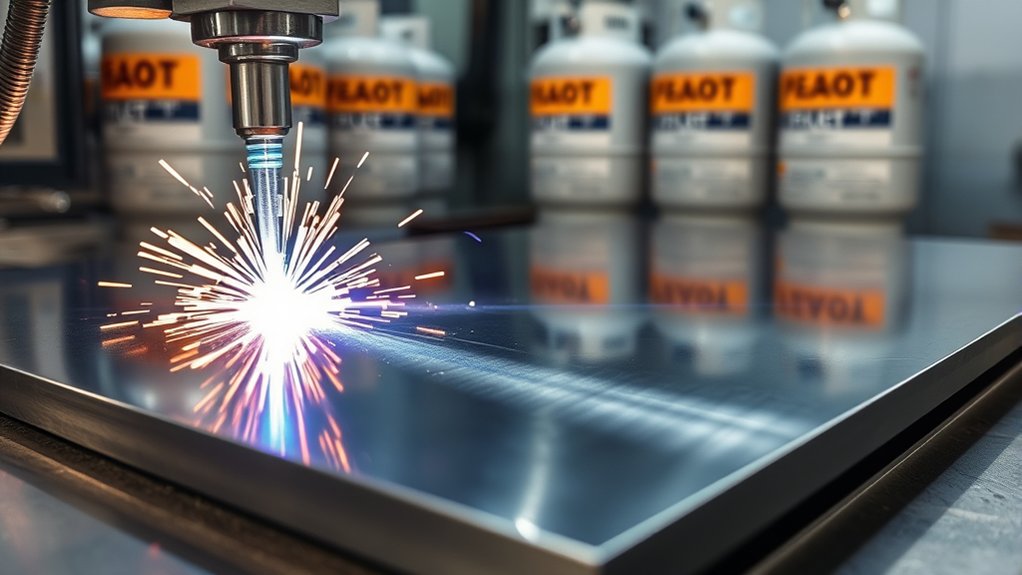

Optimal Cut Quality and Gas Selection

When aiming for peak cut quality on stainless steel, your choice of plasma and shield gases is critical.

For thicknesses under 5 mm, use nitrogen plasma gas, while F5 gas is ideal for cuts between 5 mm and 12 mm; for thicknesses exceeding 12 mm, opt for H2Mix plasma gas with nitrogen shield.

Additionally, make sure you adjust the cutting parameters, such as amperage, precisely according to the material thickness and manufacturer guidelines to achieve smooth edges and minimal dross.

Gas Choices Impact Quality

In the domain of plasma cutting stainless steel, selecting the right gas is essential for achieving ideal cut quality.

Nitrogen excels in gas efficiency and oxidation reduction, particularly for thicknesses under 5 mm, delivering cleaner cuts with minimal oxidation.

When cutting thicknesses between 5 mm and 12 mm, use F5 plasma gas paired with a nitrogen shield to enhance cut quality.

For thicknesses over 12 mm, H2Mix plasma gas is most effective.

While nitrogen may increase operating costs, it’s worth the expense for superior edge finishes.

The choice of shield gas—air, nitrogen, or water—also influences outcomes.

Nitrogen stands out, greatly reducing oxidation and achieving cleaner stainless steel edges.

Parameters for Smooth Edges

Achieving smooth edges in plasma cutting stainless steel hinges on precise parameters and gas selection. For ideal cut quality, consider your material thickness and choose the appropriate gas. Use nitrogen plasma gas and nitrogen or water shield gas for thicknesses under 5 mm. For 5–12 mm, F5 plasma gas with nitrogen shield gas is best. Over 12 mm, H2Mix plasma gas excels. Maintain a consistent cutting angle and constant torch speed. It reduces dross and aids edge preparation, ensuring clean finishes. Slow down towards the end for full cuts, avoiding tabs. Follow your owner’s manual for specific settings.

| Thickness (mm) | Plasma Gas | Shield Gas |

|---|---|---|

| < 5 | Nitrogen | Nitrogen/Water |

| 5 – 12 | F5 | Nitrogen |

| > 12 | H2Mix | Nitrogen |

Techniques for Cutting Various Thicknesses

Cutting stainless steel with a plasma cutter requires selecting the right technique based on material thickness to confirm precision and quality.

Your cutting techniques should be aligned with thickness considerations to optimize results. Here’s how you can tackle various thicknesses:

- Less than 5 mm: Utilize nitrogen plasma gas coupled with nitrogen or water shield gas. This combination confirms superior cut quality and minimizes imperfections in thinner materials.

- 5 mm to 12 mm: Opt for F5 plasma gas with nitrogen shield gas. This setup enhances cut quality and diminishes dross formation, making your cuts cleaner and reducing post-cut cleanup.

- Greater than 12 mm: Employ H2Mix plasma gas with a nitrogen shield gas. For thicknesses between 5 mm and 50 mm, the Vented Water Injection (VWI) process can be particularly effective.

Managing Dross and Slag Challenges

To effectively manage dross and slag when plasma cutting stainless steel, you should focus on maintaining a precise torch speed.

Adjusting the torch speed can greatly reduce dross accumulation and facilitate easier removal.

Additionally, employing heat management strategies, such as using nitrogen as a shield gas, can enhance cut quality and minimize unwanted heat effects on the material.

Torch Speed Adjustment

When cutting stainless steel with a plasma cutter, managing dross and slag requires careful adjustment of the torch speed. Achieving ideal cut efficiency involves balancing speed and precision. Adjust your torch speed within 45 to 130 inches per minute based on material thickness. This reduces dross accumulation effectively.

Consider these strategies:

- End-of-Cut Slowing: Slow down towards the end to guarantee complete cuts without leaving tabs, minimizing dross formation.

- Consistent Speed: Maintain a steady speed to reduce slag, as stainless steel dross is more ductile and adheres firmly.

- Pierce Cuts: Use longer, straighter lead-ins for effective pierce cuts, mitigating dross buildup at initial piercing.

Fine-tuning speed and torch height enhances cut quality, guaranteeing a cleaner, more efficient operation.

Dross Removal Techniques

Though cutting stainless steel with a plasma cutter results in more challenging dross removal due to its viscous nature, employing the right techniques can mitigate these issues.

Start by maintaining a constant torch speed, as variations can increase slag production. Adjust the cutting speed and pressure; higher speeds often reduce dross.

After cutting, utilize surface conditioning discs or flap discs for effective dross removal. When approaching the end of a cut, slow down to let the arc catch up, achieving cleaner results.

These post-processing techniques not only improve cut quality but also liberate you from excessive cleanup. By mastering these methods, you’ll efficiently manage dross and slag challenges, transforming your stainless steel cutting experience into a streamlined process.

Heat Management Strategies

While cutting stainless steel with a plasma cutter, managing heat is essential to reducing dross and slag formation. You’ll want to focus on minimizing heat retention and optimizing thermal conductivity to achieve cleaner cuts.

Here are three strategies:

- Maintain Torch Speed: A constant speed prevents excessive heat absorption, reducing dross. Avoid abrupt changes to limit energy retention.

- Optimize Lead-Ins: Implement longer, straight lead-ins when piercing. This stabilizes the arc and minimizes initial heat buildup, reducing slag.

- Adjust Settings for Thickness: Follow your manual for cutting thicker stainless steel, where thermal conductivity plays a pivotal role. Vented Water Injection (VWI) methods help manage heat effectively for materials between 5 to 50 mm, ensuring efficient dross control.

These strategies will help you achieve precision and freedom in your cutting projects.

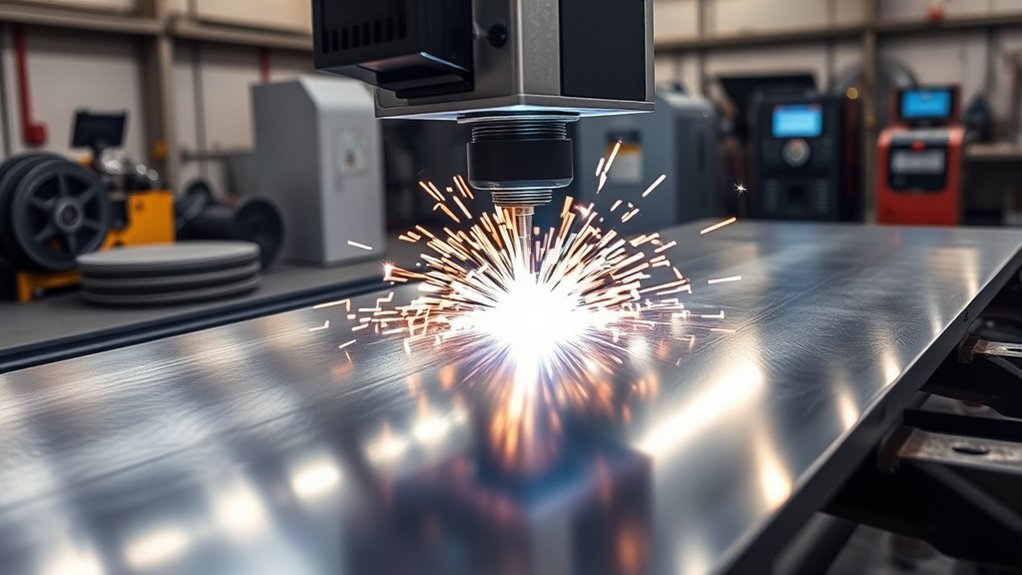

Recommended Plasma Cutting Systems

For cutting stainless steel with precision and efficiency, consider high-performance plasma cutting systems like the XPR300 and XPR170. These plasma systems are engineered for excellence, offering unmatched cutting efficiency and superior X-Definition cut quality.

The XPR300 excels with its ability to enhance productivity and reduce consumable costs, perfect for demanding applications. Meanwhile, the XPR170 is ideal for mid-range thicknesses, using next-generation X-Definition processes to guarantee precise and efficient cuts.

When selecting a plasma cutter, consider options that support various gas combinations, as they provide superior edge quality compared to basic air plasma systems. Industrial plasma systems can handle stainless steel thicknesses up to 160mm, delivering sharp edges and shiny finishes, whereas air plasma systems are limited to 25mm.

Additionally, prioritize features like CNC controls and automatic torch height control. These elements are essential for achieving the accuracy and liberation you seek in stainless steel cutting.

Safety Considerations in Stainless Steel Plasma Cutting

When cutting stainless steel with a plasma cutter, ensuring safety is paramount due to the hazardous fumes produced during the process. Hexavalent chromium, a known carcinogen, is a significant health risk, necessitating effective fume extraction systems. The exposure limit for hexavalent chromium is only 0.5 micrograms/m³.

Ensuring proper ventilation and using N95 or P100 respirators will help protect you from toxic inhalation. Additionally, electrical grounding is critical to avoid electrical hazards.

Here are three essential safety measures:

- Fume Extraction: Incorporate an efficient ventilation system to maintain air quality and comply with exposure limits.

- Respiratory Protection: Wear N95 or P100 respirators to minimize inhalation of metal fumes.

- Electrical Grounding: Properly ground all equipment to prevent electrical shocks or malfunctions.

Maintaining a clean workspace and readily available fire safety equipment will further mitigate risks from intense heat and stray sparks.

Frequently Asked Questions

What Maintenance Is Required for a Plasma Cutter Used on Stainless Steel?

Guarantee plasma cutter maintenance includes checking consumables, inspecting torch leads, and cleaning air filters. For stainless steel care, regularly clean the nozzle and guarantee correct settings for peak performance. Embrace the freedom of precision cutting with effective upkeep.

How Does Weather Affect Plasma Cutting of Stainless Steel Outdoors?

Did you know 20% of plasma cutting issues are weather-related? Humidity impacts arc stability, while wind effects can disrupt plasma flow. For ideal cuts, guarantee conditions are calm and dry, liberating your craftsmanship from environmental constraints.

Can Plasma Cutting Cause Warping in Thin Stainless Steel Sheets?

Yes, plasma cutting can warp thin stainless steel sheets. You can prevent warping by managing heat effectively. Use lower amperage settings, increase cutting speed, and guarantee sufficient cooling to maintain structural integrity and achieve precise, warp-free cuts.

What Is the Lifespan of Consumables When Cutting Stainless Steel?

When cutting stainless steel, consumable lifespan varies based on cutting efficiency and technique. You can maximize lifespan by maintaining ideal gas flow, correct amperage settings, and ensuring clean, dry air supply, liberating yourself from frequent replacements.

Are There Specific Plasma Cutters Designed Only for Stainless Steel?

You won’t find plasma cutter types designed solely for stainless steel, but many models offer stainless steel compatibility. Choose one with adjustable settings and sufficient amperage for precise cuts, liberating your projects with versatility and efficiency.

Conclusion

In the domain of stainless steel plasma cutting, you’re the maestro orchestrating a symphony of precision and efficiency. With the right gas choice—nitrogen for lighter pieces and H2Mix for the hefty ones—you’ll dance through the metal with ease. Keep your torch angle and speed in harmony to avoid a dross-laden performance. Embrace CNC controls and automatic height adjustments as your steadfast companions, ensuring each cut is a masterpiece, safe and flawless, like a well-composed sonnet.